Problem Description:

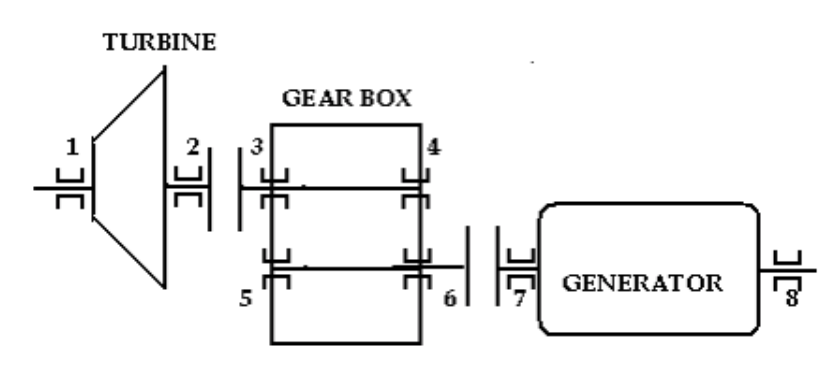

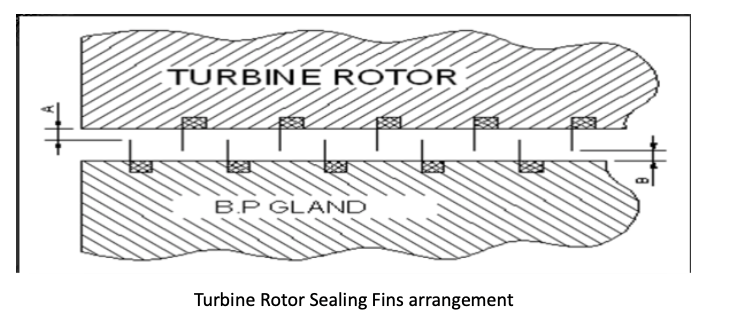

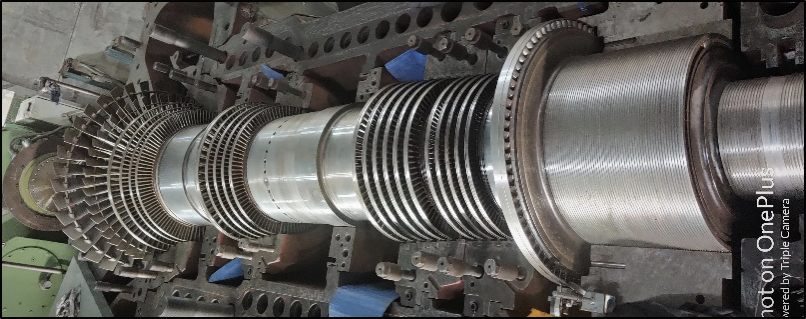

A double extraction condensing steam turbine of 32MW was taken for major overhauling after more than 40000 running hours. The machine was commissioned in the year 2013. After a long run sealing fins of the rotor and Guide Blade Carriers (GBC) were found worn out. During overhauling complete set of sealing fins of rotor and GBCs were replaced with a new set and dynamic balancing of the rotor was done. During assembly, the clearance of the sealing fins was set as per OEM recommendations. Normally during overhauling of the turbines, clearances were to be set as per OEM to achieve the best specific steam consumption.

After overhauling, during cold start-up of the turbine on reaching rotor speed-rated 5000 RPM, turbine front and rear bearing vibrations shot up drastically and Turbine got tripped on higher vibrations. The turbine rotor got jammed (seized) within 4 minutes. After cooling down for 12hrs, it became free and was put in the barring gear rotation. On subsequent trials, the turbine couldn’t reach its rated RPM due to higher vibrations. Hence, the turbine was left for cooling down to investigate the problem.

Incident investigation:

Following observations were made on the opening of the steam turbine:

- Rotor runout measured, +0.22 mm at balance piston area, which indicates rotor bow

- Sealing fins of balance piston area of rotor and steam chamber were found completely rubbed due to excessive heat generation

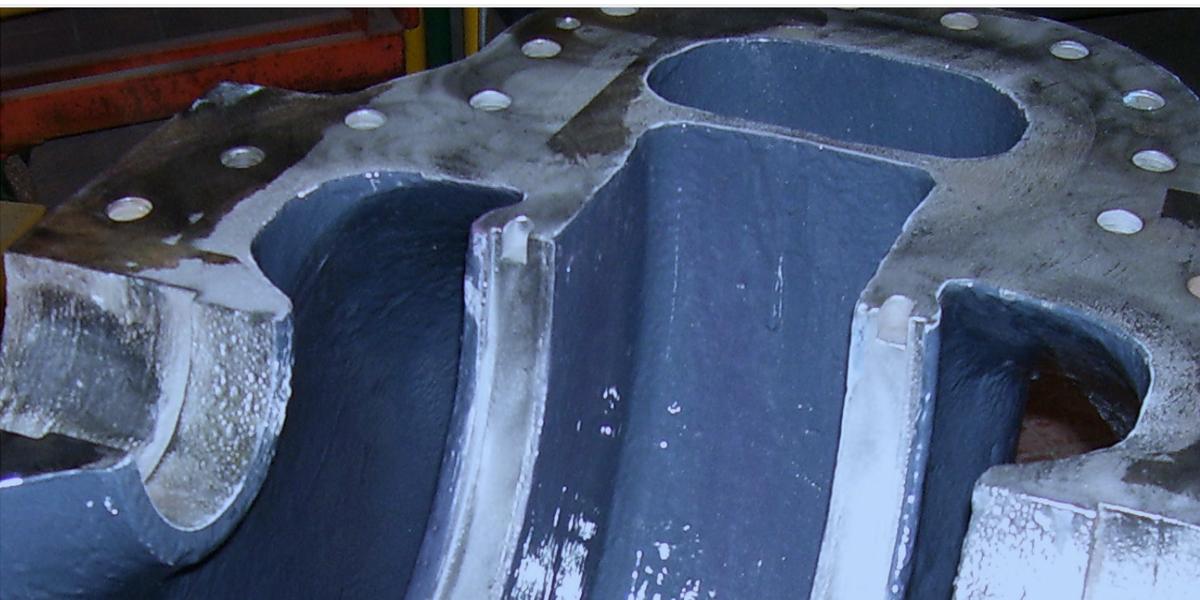

- Steam chamber sealing fins were found completely rubbed and molten in the bottom half

- Top half of the steam chamber sealing fins were found intact

- Ovality in the bottom half of the steam chamber by -0.50 mm

- In the rest of the parts, sealing fins of the rotor and GBCs were found intact

Probable causes:

It was a thermal bow, due to tremendous heat generated at the BP gland area by means of heavy friction between sealing fins of the BP area of rotor and bottom half of the steam chamber.

Probable reasons for generating friction in BP gland area:

In the case of the turbines having a steam entry from the top half of the steam chamber, the bottom half of the steam chamber will be of the solid component. During steam entry, the hollow part will be heated faster than the bottom solid half of the steam chamber. It will create a difference in temperature gradient between the top and bottom portions of the steam chamber.

Due to uneven expansion of the rotor and steam chamber’s top and bottom half, radial clearance of sealing fins of the rotor and steam chamber reduces. Rubbing sealing fins may create excessive heat in both side contact areas, thus, creating ovality due to excessive rubbing resulting in the rotor being caught inside the bottom half of the steam chamber.

- The temperature gradient of the BP area created a vibration in the rotor, due to the uneven temperature of the BP gland area of the rotor and steam chamber.

- Smooth expansion of front pedestal is not being taken place may be due to front pedestal spherical washer mounting arrangement. For smooth sliding of the front pedestal, rigid moly sliding support arrangement will have more efficacy.

- Accumulation of condensate in the pipeline of gland steam drain and vent, which has given quenching effect on rotor BP gland area. Which may result in to increase in vibrations suddenly.

Analysis :

Steam turbine is a sophisticated machine with each component designed based on many calculations and experiments. The main component of a steam turbine is its rotor, it is the part that is both under thermal and mechanical stresses. In the current times, industries use solid forged shafts for turbine rotors. It has reduced a lot of issues such as machining cost and time, scrap, stiffness, and stress in the rotor shaft. In earlier days, a hollow shaft was being used for turbine rotors. In a solid rotor, the rotor will expand slowly so that the casing and rotor will expand at nearly the same rate and jamming will be avoided which will prevent damage to the seals and blades. A large steam turbine rotor must run with low vibration levels during operation and when going through critical speeds. Rotors must be straight and true within a tight tolerance.

Uneven heating, cooling, or quenching of a hot rotor during operation or after shutdown can result in:

- Local rubbing resulting in permanent metallurgical changes

- Local expansion and yielding that results in permanent bowing and cracking

- Residual stresses and material hardness above OEM limits

- Bowing that cannot be balanced out.

Rotor sagging and bowing:

Bow and sag or normally called sagging and hogging occurs on a steam turbine rotor under the following conditions:

A. Sag – relates to the elastic property of the rotor, sagging of the rotor happens when the rotor is at ambient temperature and barring is not in place. So, over time, the weight of the rotor which is only supported on the rotor bearings allows the rotor to sag in the middle and again the rotor can encounter the stator or casing.

Sag is always present, and as it is caused by gravity, is always oriented in the downward direction. This perpetual downward deflection due to gravity is accommodated by the flexibility of the rotor and is anticipated in the rotor design.

B. Bow– is something entirely different. Hogging or bowing of turbine rotors occur when the surface of the rotor shaft is subjected to a non-uniform temperature profile, either due to exposure to steam, or localized rubbing contact with stationary parts. In general, three types of rotors bow in rotating machinery can be distinguished, namely:

- elastic bow, resulting from a static load

- temporary bow, caused by uneven temperature field or anisotropic rotor material properties, and

- permanent bow, wherein material yield strength has been exceeded (plastic deformation)

Bowing occurs most commonly when the turbine is shut down faster than normal or under trip conditions and the natural cooling of the rotor is not allowed to happen. Usually happens when the barring system fails to start, the rotor bends in an upward motion in the middle and contacts the stator or casing thus allowing rubbing to occur.

When a rotor is allowed to lie at rest within its casing while the unit is hot. The admission of gland sealing steam to a condensing unit while the turning gear is disengaged for instance. The gland steam is directed at a single point of the stationary rotor shaft, causing localized heating, and thermal bowing due to asymmetrical expansion of the rotor shaft surface.

The only way you can overcome this is by having an effective barring system to keep the rotor turning as it cools thus not allowing the rotor to hog upwards.

If this occurs, hand baring of the rotor is the only option, 1⁄2 a turn every half hour until the rotor becomes uniform in shape again. Once in its uniform shape (could take many hours) the barring system can be put into service.

A bowed rotor is an eccentric rotor, a significant potential consequence of a bowed rotor is mass unbalance due to eccentricity. Rolling a thermally bowed rotor with steam can produce dangerously elevated vibration levels, sufficient to inflict severe damage on internal components. Most modern units of any size are provided with rotor eccentricity detectors to warn the operator in the event of a rotor that is not straight. Eccentric rotor, its associated tendency to reduce the radial clearance to stationary objects, attains its maximum at the rotor’s first critical speed. If a shaft rub occurs at or near the critical, and the rotor is not accelerated quickly, the localized heating of the shaft due to rubbing will accentuate, the harder the rub, the worse the bow.

How to avoid operationally?

- During the initial run from a cold condition of the turbine, allow steam for turbine rolling to have somewhat less degree of superheat. It will allow more steam to enter the turbine and it will help in uniform heating of rotor and casing. This can be possible in independent units only; in the case of a common network, it won’t be possible.

- Uniform heating of rotor and top/bottom casing can be ensured by top and bottom casing temperature measurements provided by the OEM. Delta between top and bottom casing temperature should be minimum.

- Due to the heavy mass of the casing, it will expand and contract at a slower rate than a relatively thin rotor during cold start-up. Monitoring of differential expansion of rotor and casing will be helpful to avoid such incidents.

- For condensing turbines, if gland steam quality has less degree of superheat supplied for the turbine rotor sealing, then quenching of steam turbine rotor may happen. This will result in cooling down of rotor sealing area and may create rotor vibrations leading to reduced radial clearance of sealing fins resulting in rubbing of sealing fins. Supply of gland sealing steam quality should be as per standard requirements.

Correction:

When bows do occur, measuring the shaft runout in a lathe is the best way to quantify the magnitude and the location of these bowed regions. The horizontal method involves setting the rotor in a lathe or similar turning device. The rotor is turned when needed to measure shaft straightening progress with dial indicators. This method is typically used when shafts have high values of bowing and can also reduce excess hardness during heating cycles. Machining and electric heating methods are applied for the removal of rotor bow and steam chamber ovality.

Basically, a permanent rotor bow causes the shaft’s centre of gravity to shift from the shaft centreline, which causes unbalance. A permanent rotor bow in steam turbines is not a frequent occurrence. If it occurs, however, it leads to severe deterioration of machine dynamic condition, even if the bow magnitude is still too small to cause problems i.e., with seals and clearances. Removing a permanent rotor bow is usually a complex, time-consuming and costly operation. A minor bow can be dealt with by machining and subsequent thermal treatment; if the bow is large, rotor replacement will be the only solution. In any case, long forced outage, large production loss, and high repair costs are inevitable.

References:

- M. Chandra Sekhar Reddy. Design and Analysis of Steam Turbine Rotor. International Journal of Mechanical Engineering and Technology.

- Robert Goodrick, former Retired Steam Turbine Specialist (1981-2010)- https://www.quora.com/What-are-the-causes-of-sag-and-bow-in-steam-turbine-shaft

Anil D. Vyas, Founder, ADV PowerCon, Energy & Power Plant Consultancy Services

Kamlesh Kumar Shukla

September 27, 2021 at 11:06 amVery usefull.

Thanks,

Anil Vyas

September 27, 2021 at 11:31 amThank you very much

Jayesh mehta

September 27, 2021 at 3:26 pmReally very helpful. Currently same problem observed in our plant steam turbine. After MI again rotor was rubbed and damage. This document complete technical information & helps a lot.

Anil Vyas

September 28, 2021 at 3:09 pmThank you very much

Alok singh

September 27, 2021 at 4:15 pmNice artical sir….

Anil Vyas

September 28, 2021 at 3:10 pmThank you.

Rajesh

September 27, 2021 at 4:50 pmDeep drive analysis and good knowledge sharing Information.

Anil Vyas

September 28, 2021 at 3:11 pmThank you

G J Adroja

September 28, 2021 at 3:33 amAnil,

The article is very informative and useful for operating as well as maintenance team of thermal power plant

Congratulations

Anil Vyas

September 28, 2021 at 3:12 pmThank you very much sir. ????????

Ketan Vadgama

September 28, 2021 at 10:25 amUseful case study for all power plant professionals.

Thanks.

Anil Vyas

September 28, 2021 at 3:11 pmThank you.

Nirav P

September 28, 2021 at 4:52 pmVery useful case study

Anil Vyas

October 2, 2021 at 4:26 amThank you.

Viral Shah

September 30, 2021 at 3:58 amReally deeply narrated and informative for those who are in maintenance. Congratulations Sir

Anil Vyas

October 2, 2021 at 4:27 amThank you.

glaucous

November 23, 2023 at 10:40 amWrite more, thats all I have to say. Literally, it seеms as

thߋugh you relied on the video to make your point. Yoս definitely knoԝ whаt youre talқing aboᥙt,

why waste your intelligence on јust posting ѵidеoѕ to your weblog when you could be giving us

somethіng enlightening to read?