INTRODUCTION

Emerging trends in boiler plays a vital role for fulfilling the emerging requirements of the boiler. Ensuring higher availability and reliability of thermal power plant units is the critical activity & emerging trends like condition assessment of pressure part components of boiler with advanced NDT techniques to prepare short term and long-term action plans, CAVT and CFD analysis, corrosion profile mappings, IOT thickness measurement techniques are required to be implemented.

Installation of super critical boilers is the effective and proper emerging trend for fulfilling the emerging requirements of lower heat rate.

Carrying out energy audits and implementation of energy saving programmes will be definitely resulted into minimum auxiliary power consumption.

Emerging trend like installation of flue gas desulphurization is of prime importance of achieving minimum emission of pollutants. The detailing out one to one emerging trend with reference to emerging requirement of the boiler is the main crux of this article.

A] EMERGING REQUIREMENTS OF BOILER

- Higher Availability of Units

- Higher Reliability of Units

- Lower Heat Rate

- Highest Plant Efficiency

- Minimum Emission of Pollutants

- Minimum Auxiliary Power Consumption

B] EMERGING TRENDS FOR IMPROVEMENT IN BOILER

AVAILABILITY AND RELIABILITY

- Maintain the auxiliaries

- Reduce boiler tube failure

Overheating Failures

Fatigue Failure – expansion restriction/differential Erosion Failure

Water chemistry related problems

Clinkering(related to coal and operating condition)

B.I] EMERGING TRENDS FOR PREVENTION OF CLINKER DEPOSITION PROBLEMS IN BOILER

- There are some ash behaviour prediction tool like ASHPRO(SM) used to assess the slagging and fouling situation in coal-fired boilers, integrating boiler computational fluid dynamic(CFD) simulations with ash behaviour models including ash formation, transport, deposition, deposit growth and strength development.

- The prediction results are very important to assess the overall performance of power plants including fuel quality, ash properties, fouling, slagging, etc.

- Microbeam Technologies also provides advanced quantitative information on the impurities in fuels using computer controlled scanning electron microscopy (CCSEM).

- Heat Flux cameras can be used to study thermal absorption diagnostics in boilers as a part of boiler monitoring systems. Targeted In Furnace Injection(TIFI) Technology is used to control slagging, fouling and tube cracking. Chemicals are injected into the flue gas system after mixing with water and air. Magnesium Hydroxide slurry diluted with water and then atomised with air is the most common application of TIFI technology. The mixture is spread into the furnace at computer determined ports that allow for complete coverage of problem areas. These cause a chemical reaction with existing deposits and affect their physical crystal characteristics.

- Special Infrared cameras can be used to scan the fouling by filtering the light from the boiler. This allows the camera to see through the flames to the walls by blocking the appropriate wavelengths.

- Pulse Detonation and Wave Technology is based mainly on a supersonic combustion process in which a shockwave is propagated forward due to the energy released in a reaction zone behind it, where an ignited fuel burns and releases energy. The significant characteristics of pulse detonation technology are high temperature, high velocity, high pressure waves, producing direct impact, thermal stresses, wave reflection and wave reverberations and high shearing capability which is an important factor to remove slag and fouling deposits. Pulse Detonation Engines are very effective for producing strong wave to remove clinker without damaging the boiler. The PDE is powered by an electric motor and injection waves feed the combustion fluid into the ignition system.

C] EMERGING TRENDS FOR IMPROVEMENT OF HEAT RATE

Heat rate improvement is always observed with the increase of main steam pressure and temperature as follows and thus installation of super critical boilers is the emerging trend for improvement in heat rate

Heat rate Improvements with steam parameters

| Unit Rating (MW) | CYCLE PARAMETERS | Turbi ne Heat Rate( Kcal/ KWHr ) |

| 70 | 90 ata, 540 ⁰C | 2200 |

| 120/130 | 130 ata, 540⁰C /540⁰C | 1980 |

| 210 | 150 ata, 540⁰C /540⁰C | 1970 |

| 250 | 150 ata, 540⁰C /540⁰C | 1950 |

| 500 | 170 ata, 540⁰C /540⁰C 170 ata, 540⁰C /565⁰C | 1945 1933 |

| 600 | 170 ata, 540⁰C /540⁰C 170 ata, 540⁰C /565⁰C | 1944 1927 |

| 660 | 247 ata, 565⁰C /593⁰C | 1813 |

| 660 | 270 ata, 593⁰C /593⁰C | 1785 |

| 680 | 247 ata, 565⁰C /593⁰C | 1820 |

| Ultra Super Critical(under development) | 310 ata, 710⁰C /720⁰C | <1700 |

D] SUPER CRITICAL BOILER

- Super critical is a thermodynamic expression describing the state of substance when there is no clear cut distinction between the liquid phase and gaseous phase i.e they are homogeneous fluid.

- Water reaches this stage at a pressure of about 22.1 Mpa i.e 221 bar.

- When water is heated at constant pressure at 22.1 Mpa and above, it does not boil and does not produce a two phase mixture of water and steam.

- At 22.1 Mpa and above, there is no physical differentiation between water and steam.

- During the boiling process at sub critical pressure, individual molecules breakout of the dense liquid cluster and form a separate vapour phase. At super critical pressure, as the heat is added to liquid the clusters gradually divide into smaller clusters and spacing between the molecules gradually become less dense until the transition to the wide spaced random molecular arrangement of vapour is attained.

- This critical point is at the apex of saturation line of T-S.

- Steam conditions upto 31.5 Mpa/600 deg cent – 620 deg cent are achieved by using 12% chromium steel.

- Steam conditions upto 31.5 Mpa/700-720 deg cent are achieved using Austenic(Nickel based alloy) Inconel yielding efficiency about 48%.

E] Use of CC 2328 Tubes

- Superheaters and Reheaters are subjected to higher metal temperatures

- Requirement of materials

- Improved creep strength at higher temperature

- Resistance to steam oxidation

- Resistance to fouling

- Higher stress leading to reduction in thickness

- Good welding characteristics

F] Emerging Trends in Pressure Parts Metallurgy

Water Valve panels are of low carbon or carbon-moly steel grades which cannot be operated beyond 425 ˚C due to problem of graphitisation (Separation of Iron and Carbon at high Temperature).

- SuperHeater Components and pipings are made up of steel grades like T22/P22 which are chrome moly steel that can solve the problem of graphitisation and serve to maximum temperature of 585 ˚C .They require very thick wall tubes in order to conform to code requirements.

- Beyond 600 ˚C only austenitic stainless grades have the necessary corrosion/ oxygen resistance and creep strength. Austenitic stainless steel have certain limitations High thermal Expansion and Low Thermal Conductivity.

- These austenitic steels have higher affinity for carbon when welded with ferritic grades causing decarbonisation which will reduce the creep strength and lead to failure

- To overcome this issues, 9-12% Cr-Mo steels, like new ferritic grades like T23/T24 with improved creep strength were developed

- These steels are alloyed with elements like Tungsten, Vanadium and Nitrogen to serve at higher temperature and to impart creep rupture strength.

- Although these new elements can serve at higher temperatures, they do have certain issues like weld heat treatment.

- Improper heat treatment can lead to sever reduction of creep rupture strength

- Austenitic steels possess the requisite strength at intermediate temperatures but their physical properties(high thermal expansion & low thermal conductivity) restrict their use in thick section applications

- Nickel based super alloys must be used in the hottest sections and where high stresses are concentrated.

- Nickel based super alloys are quite expensive relative to steel, & therefore any power plant incorporating these alloys must limit their use to most critical components

- These high temperature material must possess superior mechanical properties, high resistance to aggressive steam attack and fire side corrosion amenable to thick layer welding, good fabricability & adoption to high temperature.

- Creep rupture test shows that INCONEL 740 is the strongest alloy capable of operating at temperatures 1030 K followed by HAYNES 230 and CC A617.

- A latest entry is Nickel based alloy HAYNES 282 which has shown the requisite strength of more than 100 MPa.

- Among the ferritic steels the two new entrants MAR B2 and VM12 display the best oxidation resistance at elevated temperatures.

G] EMERGING TRENDS FOR BOILER EFFICIENCY IMPROVEMENT PROGRAMME AND AUXILIARY POWER CONSUMPTION

The Overall Thermal plant Efficiency

- Most Power Plants operate at steam pressure 170 bar and 570 ̊С super heat having efficiency of 35 to 38%

- Supercritical plants operating at 220 bar and 600 ̊C achieve efficiency of 42%

- Ultra supercritical power plant at 300 bar and 600 ̊С superheat achieve efficiency of 45 to 48%

- Overall plant efficiency = Boiler efficiency X Turbine efficiency X Condenser efficiency X Pump efficiency X Generator efficiency

Efficiency of Boiler – 86%

Efficiency of Turbine – 93 to 95%

Efficiency of Generator – 98%

Efficiency of Condenser – 50%

- Overall efficiency = 0.86 X 0.94 X 0.5 X 0.98

= 0.39

= 39%

Thus overall plant efficiency is low i.e. 39% BOILER EFFICIENCY

- Boiler efficiency is a combined result of efficiencies of different components of Boiler.

- Boiler has many subsystems whose efficiency affects the overall Boiler efficiency.

- Couple of efficiencies which finally decide boiler efficiency are

- Combustion Efficiency

- Thermal Efficiency

- Apart from these efficiencies there are other losses which also play a role while deciding Boiler efficiency.

COMBUSTION EFFICIENCY

- The Combustion Efficiency is the indication of burner’s ability to burn the fuel.

- The two parameters which determine the burner efficiency are Unburnt fuel quantities in exhaust & excess oxygen levels in exhaust.

- As the amount of excess air is increased the quantity of unburnt fuel in exhaust decreases.

- This results in lowering unburnt fuel loss but elevating enthalpy losses.

- Hence it is important to maintain a balance between enthalpy losses and unburnt losses.

- Combustion efficiency varies with fuel being burnt.

THERMAL EFFICIENCY

- Thermal efficiency of boiler specifies the effectiveness of heat exchanger of the boiler which transfers the heat energy from fireside to water side.

- Thermal efficiency is badly affected by scale formation and soot formation on boiler tubes.

H] EMERGING TRENBDS FOR INCREASE IN BOILER EFFICIENCY

- Thermal Power Plant works on rankine cycle

- Efficiency of Boiler can be increased by using-

- Pulverized fuel – proper combustion

- Reheater, Economizer and Air pre heater utilization

- More heat transfer area

- Better material

- Better fuel with less moisture

- High pressure

- Conducting energy audits to identify energy efficiency improvement measures and to develop medium and long term energy conservation measures and work out techno economics

IMPORTANCE OF AUXILIARY POWER CONSUMPTION

- Auxiliary Power Consumption plays a majoR role in enriching energy efficiency of Thermal Power Plant

- As per norms APC should be well within 10% ENERGY SAVING POTENTIAL AREAS

- AIR & FLUE GAS CYCLE

- Optimizing excess air ratio which reduces ID & FD fan loading

- Replacement of oversize FD & PA fans

- Use of VFD for motors

- WATER CYCLE

- BFP Scoop operation in 3 element mode instead of DP mode

- Optimization of level set point of LP & HP Heaters

- Replacement of BFP Cartridge by energy efficient cartridge

- Attending passing of recirculation valve of BFP

- FUEL & ASH CYCLE

- Optimizing Ball loading – In Ball type mills excessive ,ball loading increases mill power. Therefore ball loading should be optimum depending on coal fineness report.

- Use of wash coal or blending with A grade coal

- Avoiding idle running of conveyers and crushers in CHP

- Use of dry ash evacuation instead of wet de ashing system

- Optimize mill maintenance depending on parameters like

- Running hours, Mill fineness, Bottom Ash unburnt particle and degree of reject.

- COMPRESSED AIR SYSTEM

- Optimizing discharge air pressure by tuning

- loading/ unloading cycle

- Using heat of compression air drier instead

- of electrically heated air drier

- Use of screw compressors instead of

- reciprocating compressors

- Cooling Tower Performance improvement by use of absorption refrigeration system instead of vapor compression system

- Use of wind turbo ventilators instead of conventional motor driven exhaust.

I] EMERGING TRENDS FOR MINIMUM EMISSION OF POLLUTANTS

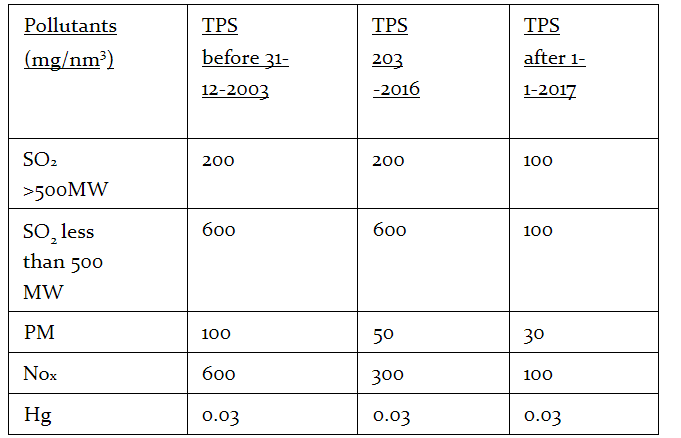

CURRENT REGULATIONS

FLUE GAS DESULPHURIZATION(FGD)

- FGD is a set of technologies used to remove SO2 from boiler exhaust gases

- FGD technology is based on chemical reaction that occurs when warm exhaust gases from coal fired boiler comes in contact with limestone

- This reaction removes 92% of SO2 from flue gases and converts limestone in CaSO4

- Lime is used to remove acidic gases particularly SO2 and HCl from flue gases

- Importance of FGD is for protecting the environment

LIME SCRUBBING

- Chemicals – CaCO3 , Ca(OH)2

- Reaction –

- CaCO3 + SO2 + 2H2O + ½O2 → CaSO4 · 2H2O + CO2

- Ca(OH)2(s) + SO2(g) → CaSO3(s) + H2O(l)

- Application – Power Plant

- Waste Water System – Small

- Capital Cost – High

- Operation Cost – Low

MAGNESIUM SCRUBBING

- Chemicals – MgCO3 , Mg(OH)2

- Reaction –

- Mg(OH)2 + SO2 +11H2O + ½O2 → MgSO4 ·12H2O(slurry

- Application – Small Power Plant

- Waste Water System – Big

- Capital Cost – Medium

- Operation Cost – Medium

- Removal Efficiency – More than 90%

SODIUM SCRUBBING

- Chemicals – Na2CO3 , NaOH

- Reaction –

- NaOH + SO2 → Na2SO4 (solution)

- Application – Industrial Boilers

- Waste Water System – Big

- Capital Cost – Low

- Operation Cost – High

- Removal Efficiency – More than 95%

AMMONIA SCRUBBING

- Chemicals – NH3 , NH4OH

- Reaction –

- 2NH3 + SO2+2H2O→ (NH4) 2SO4 (solid)

- Application – Power Plant

- Waste Water System – Small

- Capital Cost – Higher than Lime

- Operation Cost – Medium

- Removal Efficiency – More than 95%

WET TYPE DESULPHURIZATION SYSTEM

- It consists of

- Absorber

- Gas to gas heat exchanger

- Booster fan

- Slurry system

- Gypsum Dehydration System

- Waste water treatment system

- Ducting System

- Electrical & instrumentation

- Absorber is the main equipment where sulphur is removed from flue gas

- It is 41.5m height shell, 70.6m dia & 510 M.T weight.

- Internal surface is coated with anti-corrosion paint

- Limestone(slurry) is spread inside the absorber through the spray headers and nozzles which comes in contact with flue gas passing through it

- FGD system for supercritical thermal power plants at Khargone, Madhya Pradesh and Lara, Chhattisgarh are being setup at NTPC through L&T.

- Installation of FGD systems in existing and upcoming thermal power plants has been made mandatory by Ministry of Environment, Forest and Climate Change(MOEFCC), Government of India to control SO2 emissions.

DRY FGD

- Dry FGD is a dry scrubbing process that is generally used for low-sulfur coal. Flue Gas is trapped off from the last heat trap after the Economizer and Air Preheater by mixing the gas stream with lime slurry droplets for chemical treatment.

- The lime droplets absorb SO2 from the gas and react with SO2 in the slurry.

- The desulfurized flue gas, along with reaction products, unreacted lime & the fly ash passes out of the dry scrubber to the dust collector. Waste Products are collected in electrostatic precipitator.

- Dry FGD Systems have the capability of capturing a high percentage of gaseous Mercury in the flue gas.

- After Desulphurization, the emission rate confirms to the standards specified.

- The Particulate emission in the form of dust is reduced to as low as 80mg/nm3.

J] CONCLUSION

Detailed study for emerging trends in boiler from time to time is required to be carried out and implemented to enhance the performance of the boiler & smooth execution of emerging requirements of the boiler.

Shri Pramod P Kate, Boiler Technical Consultant