Name: Dr Renu N. Gupta

L&T Heavy Engineering

Head – Design for Manufacturing

Name: Dr Krishnan Shivraman

L&T Ltd.

Sr. DGM Manufacturing Technology

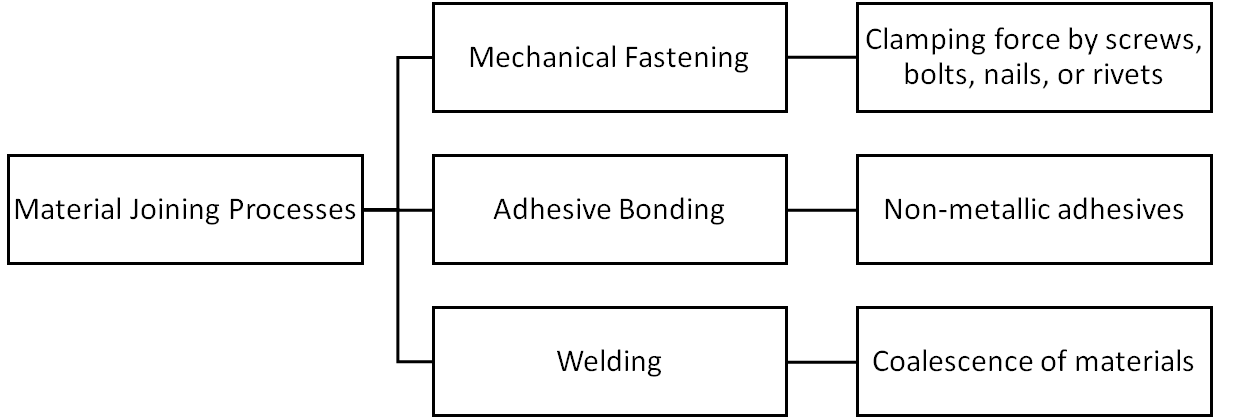

Material Joining Processes

Welding: A joining process that produces coalescence of materials by heating them to a suitable temperature with or without the application of pressure, and with or without the use of a filler material.

Coalescence: Melting together base metal and filler metal or base metal only.

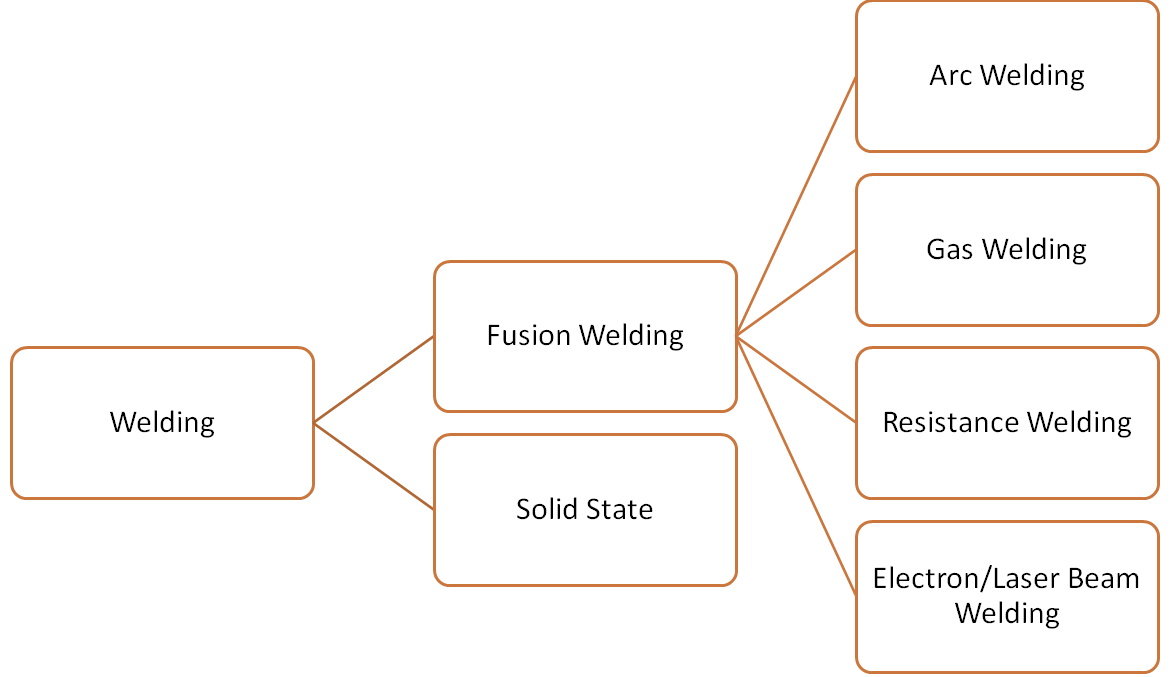

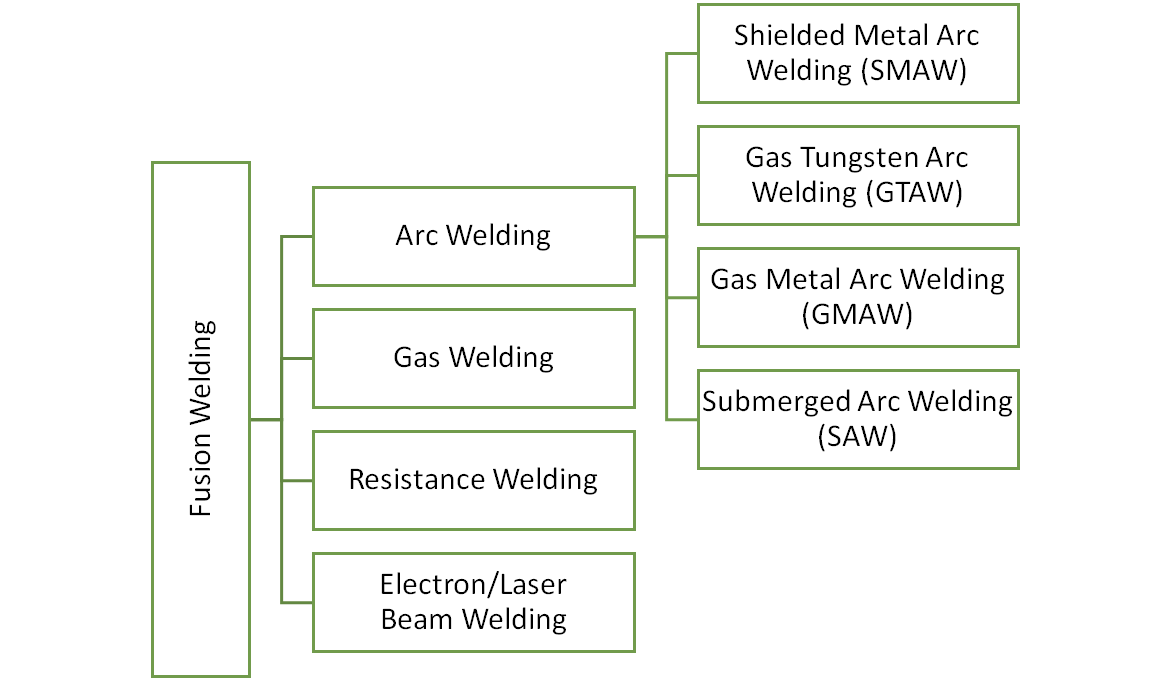

Fusion Welding

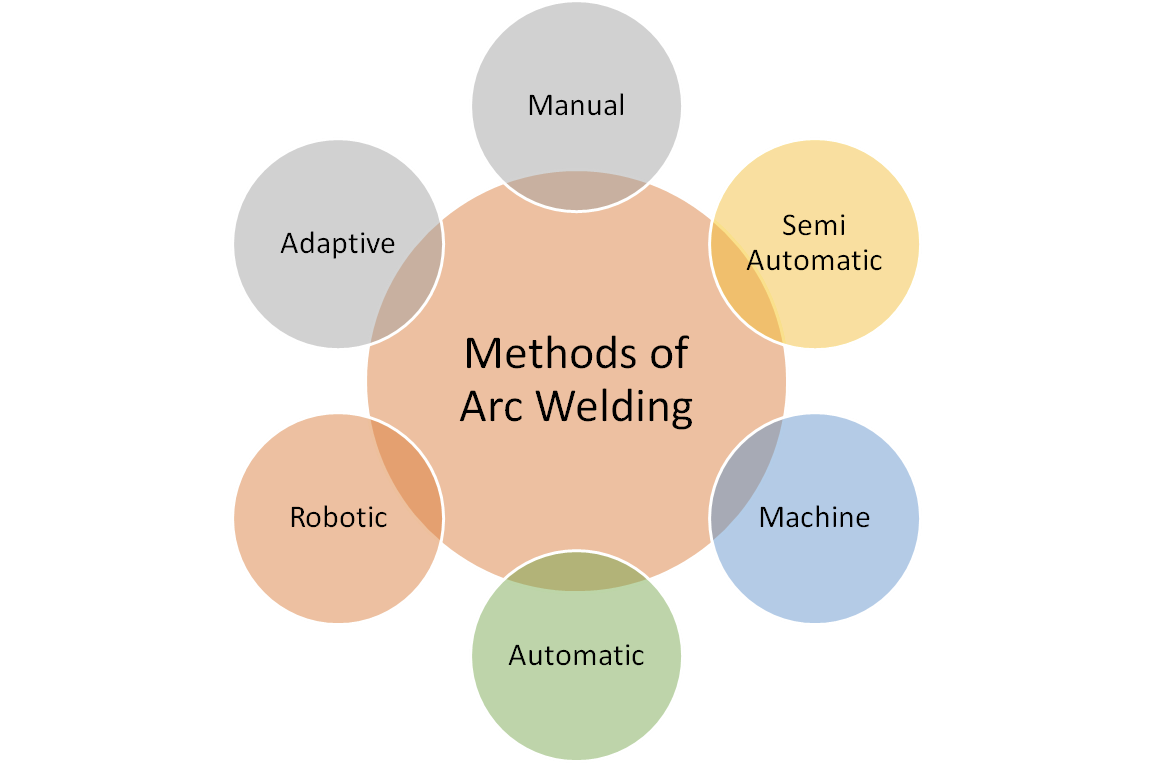

Methods of Arc Welding

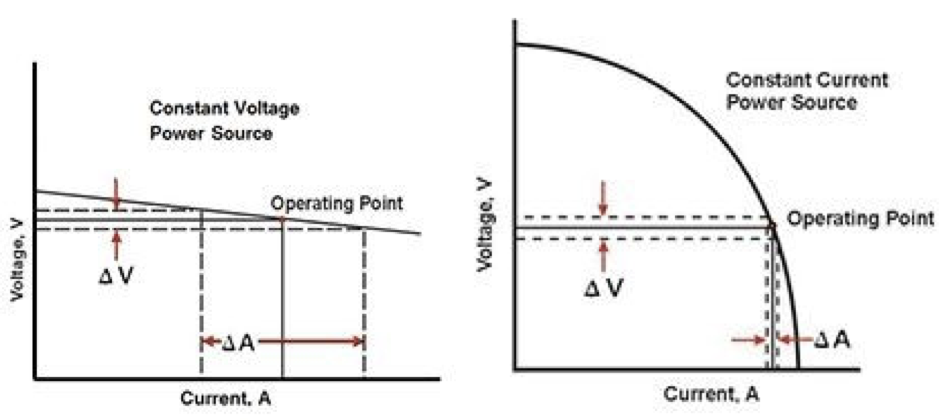

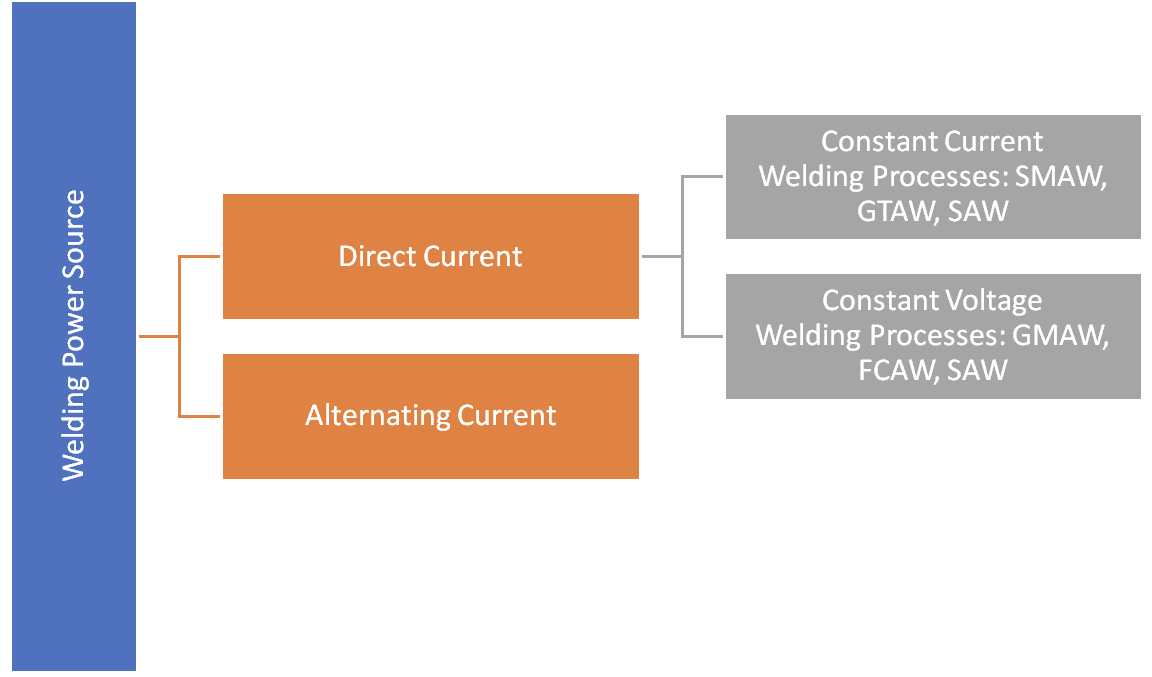

Welding Power Source

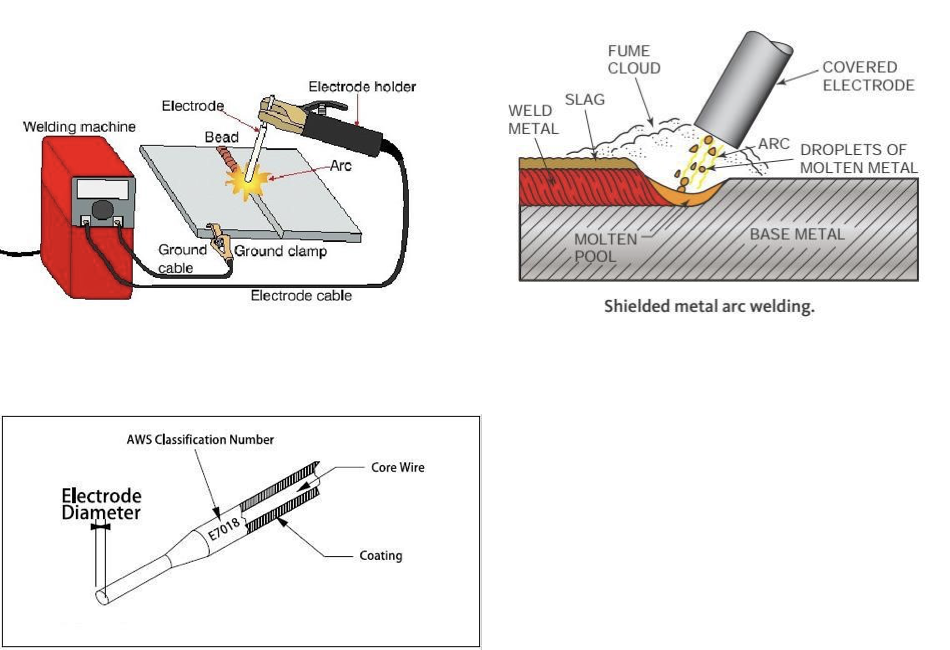

Shielded Metal Arc Welding (SMAW)

SMAW Equipment

Welding Power source: CC

Polarity: DCEN/DCEP/AC

SMAW Filler Metal

Electrodes for SMAW Consist of

- Core wire

- Flux coating

Functions of covering electrodes

- Shield the arc from the atmosphere by shielding gas from the decomposition of certain ingredients of the coating

- Deoxidizer for scavenging and purifying the deposited weld metal

- Slag formers to protect the deposited weld metal from oxidation

- Ionizing elements to make the arc more stable

- Provide alloying element to improve the strength and physical properties of the welded metal

Advantages

- Lower equipment cost – simple and inexpensive equipment

- Lightweight and portable

- Built-in shield – No exterior shielding gas is needed

- Versatile – Can be used with a variety of different materials and in different positions

Disadvantages

- Lower productivity

- Less deposition

- More number of start-stop points

- Spatter and slag clean up

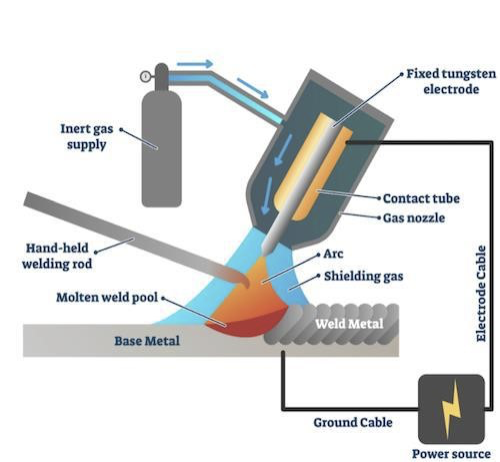

Gas Tungsten Arc Welding (GTAW)

GTAW Equipment

Welding Power Source: CC

Polarity: DCEN/AC

Shielding Gas: Ar or He

Methods of Application

| Torch Control | Filler Metal feed | |

| Manual | By hand | |

| Semi-Automatic | By hand | Equipment |

| Automatic | Equipment | Equipment |

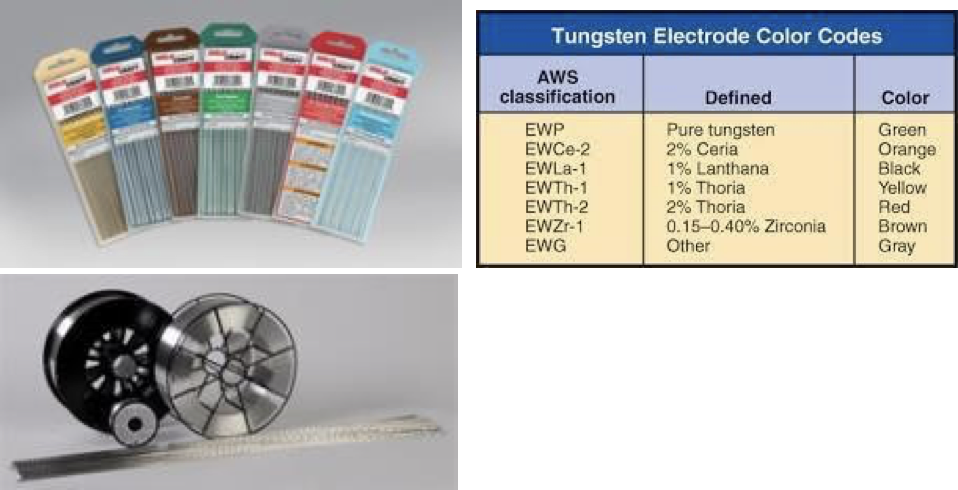

Tungsten Electrode and Filler Metals

Tungsten Electrode

- Highest melting point: 3410°C

- The classification and colour code are listed

Filler Metal

- Bare solid (Rods and Spools)

- Available in size range 0.8-2.4 mm

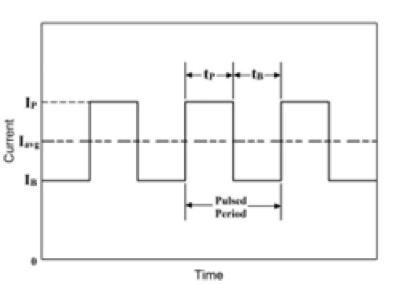

Pulsed GTAW

1. Welding current continuously changes between two levels

2. Peak current heating and fusion

3. Background current cooling & solidification

4. Reduces heat Input, increases travel speed and gives consistent quality

5. Controls distortion on thinner material

Advantages

- Clean and high-quality welds

- Welds wide ranges of metals

- No spatter or slag, sparks, or smoke

- Allows welding in all position

Disadvantages

- Lower deposition rate

- Requires a high level of operator skill

- High Levels of UV rays

- Requires good eye and hand coordination to achieve quality weld in manual GTAW

- Requires precise part location and fit-up in automatic GTAW

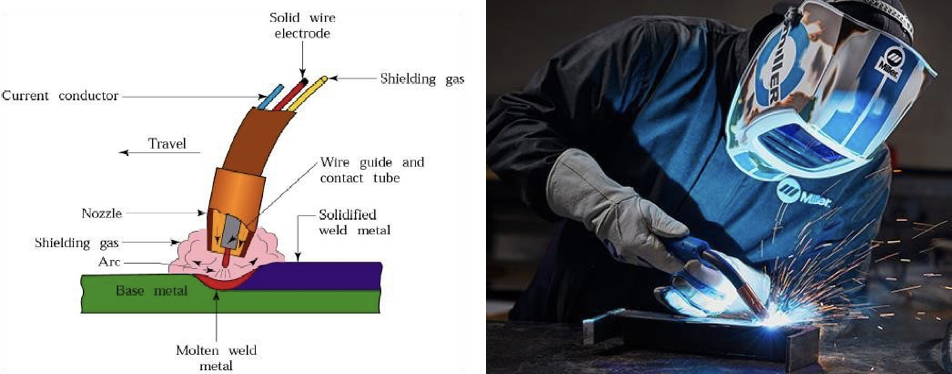

Gas Metal Arc Welding (GMAW)

Arc welding process that uses an arc between a continuous filler metal electrode and the weld pool.

GMAW Equipment

Welding Power Source: CV

Polarity: DCEP

Shielding Gas:

Inert Gases (Ar, He)

Active Gases (CO2, Ar + CO2)

Methods of Application

| Torch Control | Filler Metal Feed | |

| Semi-Automatic | By Hand | Equipment |

| Automatic | Equipment | Equipment |

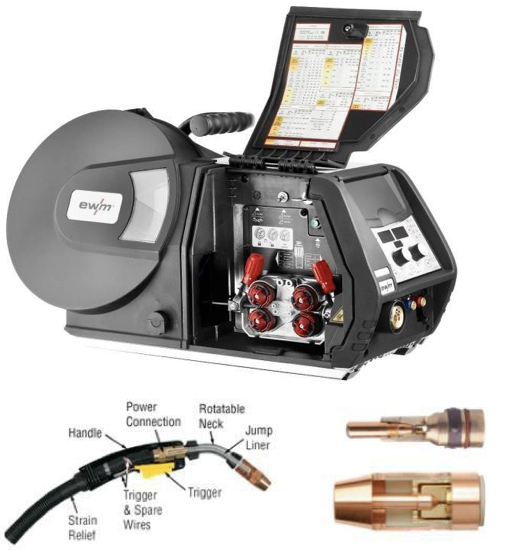

Wire Feeder and GMAW Torch

Wire Feeder

- Drives the electrode wire spool through cable and gun to a welding arc

- A constant speed wire feeder is used with a constant voltage power source

GMAW Torch

- Carry electrode wire, welding current, and shielding gas to the welding arc

- Consist of: Nozzle – Directs the flow of shielding gas and Contact tip – Guides wire and transfers welding current to the electrode wire

- Can be either air-cooled or water-cooled

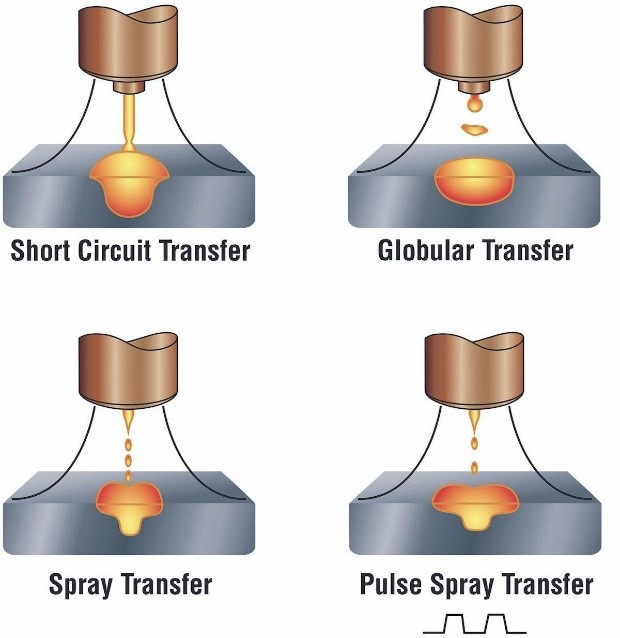

GMAW – Metal Transfer

Metal transfer refers to the transfer of molten metal from the electrode across the arc to form a weld deposit.

Advantages

- High deposition rate

- High production factor (No slag removal and continuous electrode)

- Low hydrogen weld deposit

- No stub end losses or wasted man hours caused by changing electrodes

Disadvantages

- Need shielding gas so welding in windy conditions can be difficult

- No slag means, position welds are sometimes more difficult

- Chances of lack of fusion if welding parameters and technique are not controlled

- The welding torch is difficult to get into a tight place

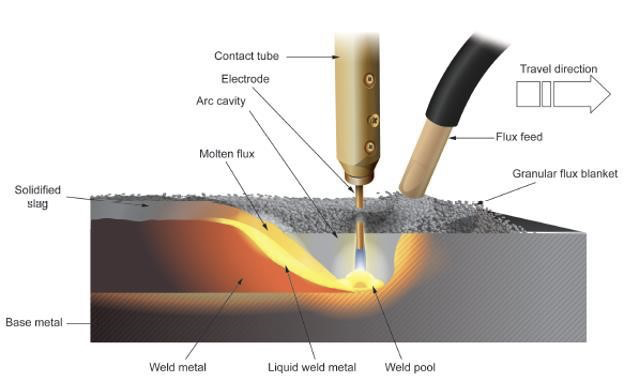

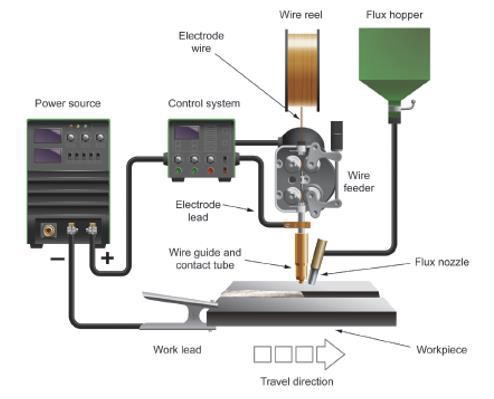

Submerged Arc Welding (SAW)

Arc welding process that uses an arc between a bare consumable electrode wire and the workpiece submerged under cover of granular fusible and molten flux filler metal electrode and the weld pool.

Welding Power Source: CC or CV

Polarity: DC or AC

Methods of Application: Machine or Automatic

SAW System consist of:

- Welding power source

- Wire feeder and Control System

- Welding torch and cable assembly

- Flux hopper and feeding mechanism

- Flux recovery System

- Travel Mechanism

- Electrode wire

- Flux

Electrode wire

- Diameter ranges from 1.6 mm to 5 mm

- LAS/CS wire copper coated to protect it from atmospheric corrosion and increase current carrying capacity

Flux

- Consists of a granular mineral compound

- Types of fluxes: Fused, bonded, and mechanically mixed

- Classified based on the mechanical properties of the weld deposit produced in combination with specific types of electrodes

Advantages

- High deposition rates and high arc on times when fully automated

- Minimal welding fume, no weld spatter and no visible arc

- Unused flux can be recovered, recycled and reused

- If metallurgically acceptable, single-pass welds can be made in relatively thick plates

Disadvantages

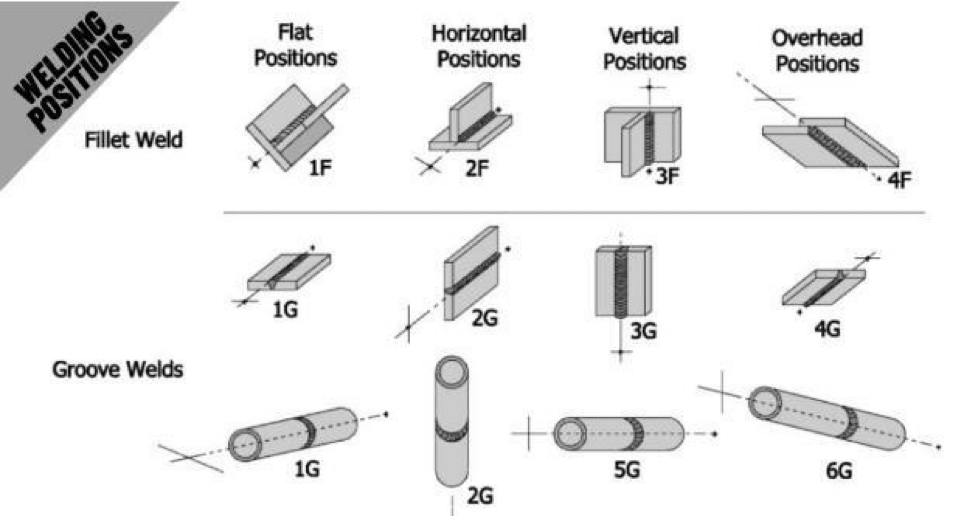

- Welding is limited to positions 1F, 1G, and 2F. Horizontal butt welds can be made but special devices are required to support the flux

- Requires separate flux handling systems and slag removal between passes.

- Not realistically applicable to thin materials

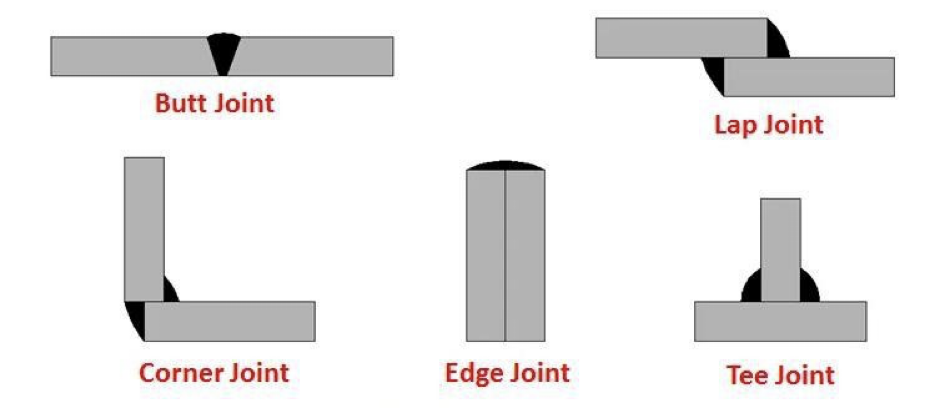

Types of Weld Joints

Welding joints are an edge or points where two or more metal pieces or plastic pieces are joined together.

Welding Position

In order to help the welder to understand the location of the weld to be made, a number and letter system is used to indicate the type and position of the weld.

Welding Codes and Standards

Standard:

A Standard can be defined as a set of technical definitions and guidelines that functions as instructions for designers, manufacturers, operators, or users of the equipment. e.g., AWS D1.1, API 1104, etc.

Code:

A standard becomes code when it has been adopted by one or more governmental bodies and is enforceable by law, or when it has been incorporated into a business contract. e.g., ASME BPVC, B31.3. B31.1, etc.

Specification:

Specification cover requirements for voluntary adoption and no enforcement is meant unless they are agreed upon between procuring agency and contractor as spelt out in the purchase order.

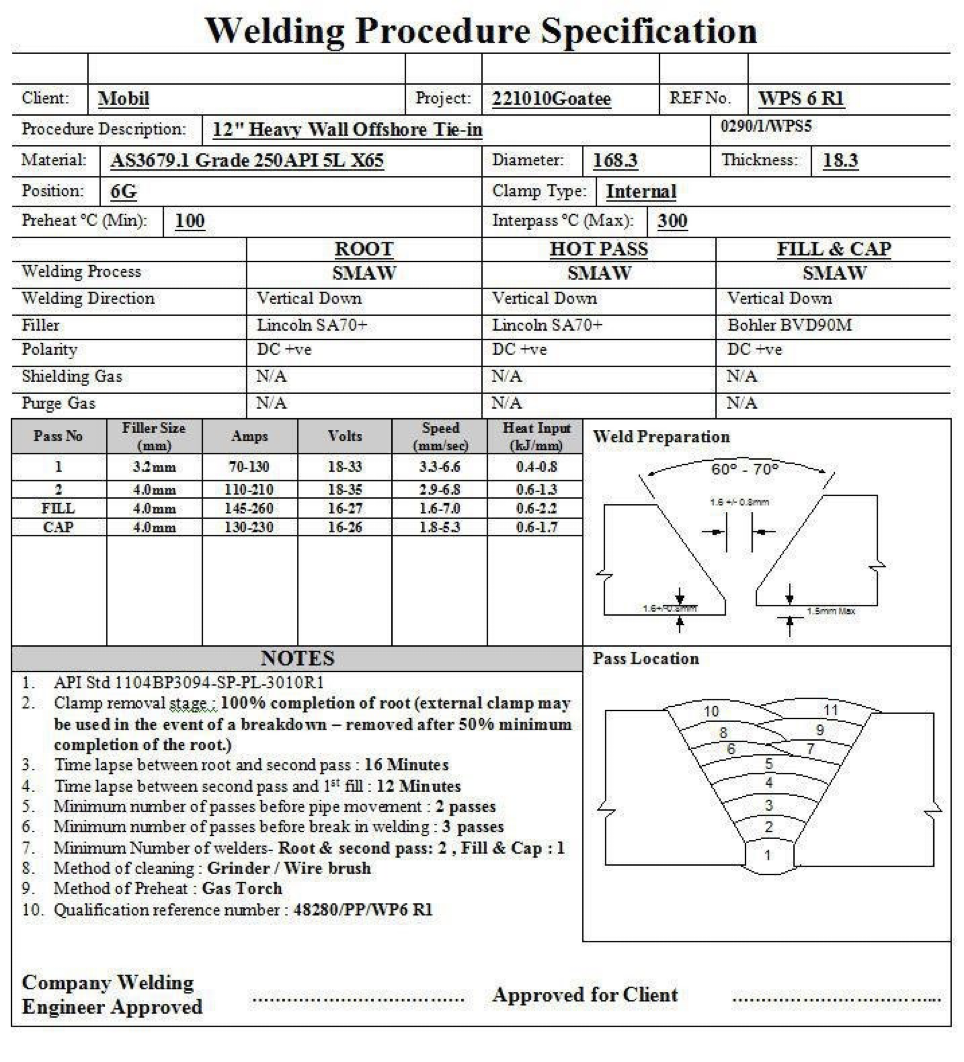

Welding Procedure Specification

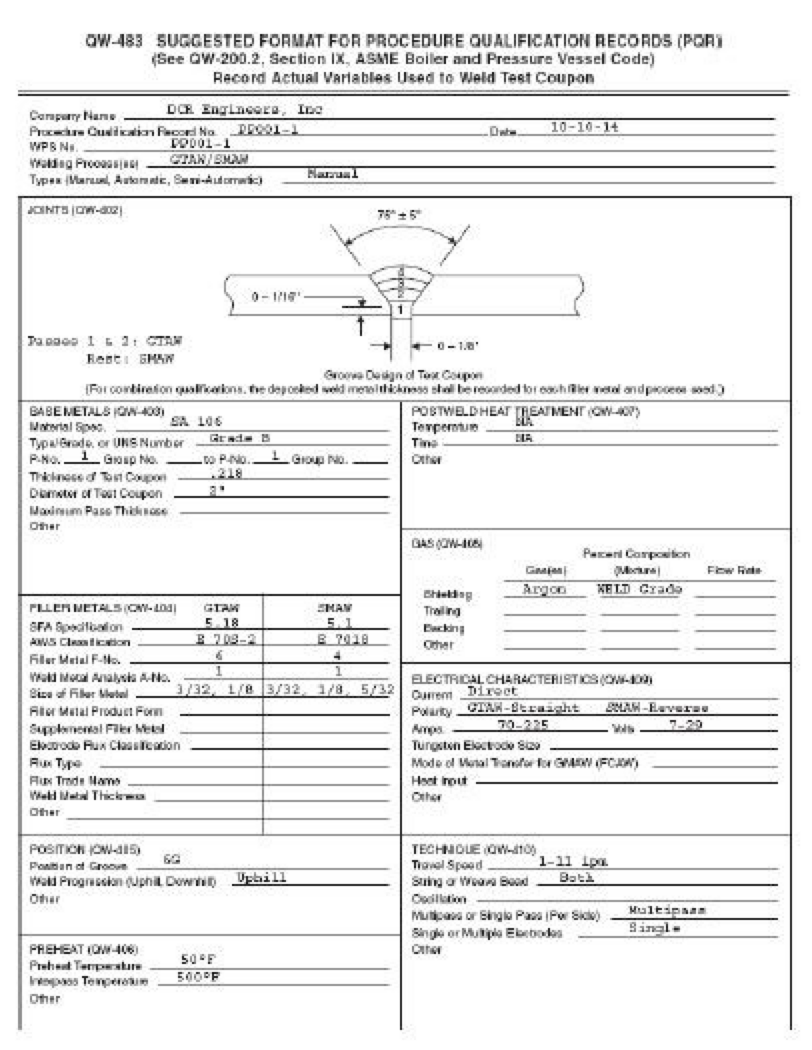

WPS (Welding Procedure Specification) is a written document to provide direction for making production welds which will meet code requirements.

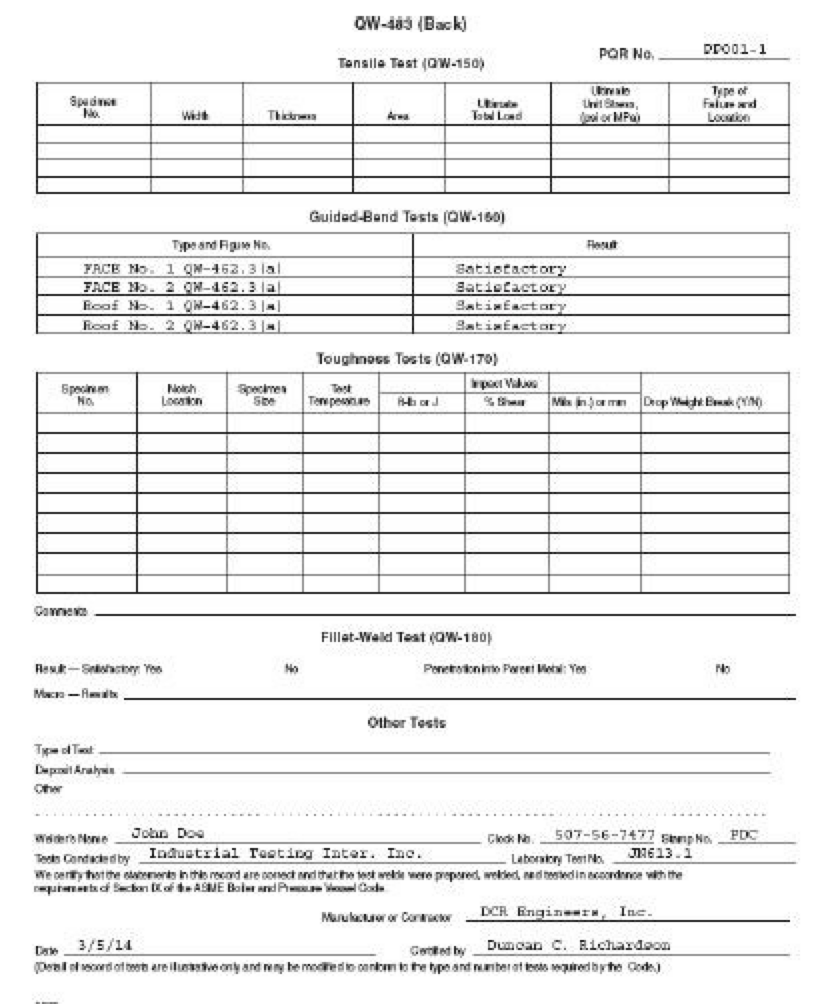

Procedure Qualification Record

PQR (Procedure Qualification Record) is the record of welding data used during the welding of test coupon and of test results.

Basic steps in Qualification of a Procedure

- Prepare preliminary WPS

- Prepare and weld a suitable test coupon using WPS

- Conduct required NDT and destructive testing

- Evaluate results of Testing

- Document results on PQR

- Issue approved PQR

- Issue approved WPS for production weld

PQR-WPS Variables Considered

- Base metal

- Welding Process

- Filler Metal

- Type of current/range

- Voltage

- Heat Input

- Travel speed

- Joint design and tolerances

- Joint and surface preparation

- Welding details

- Electrode size, passes, weave

- Position

- Post-weld heat treatment

- Shielding gas details

Need to check specific code for the list of essential variables

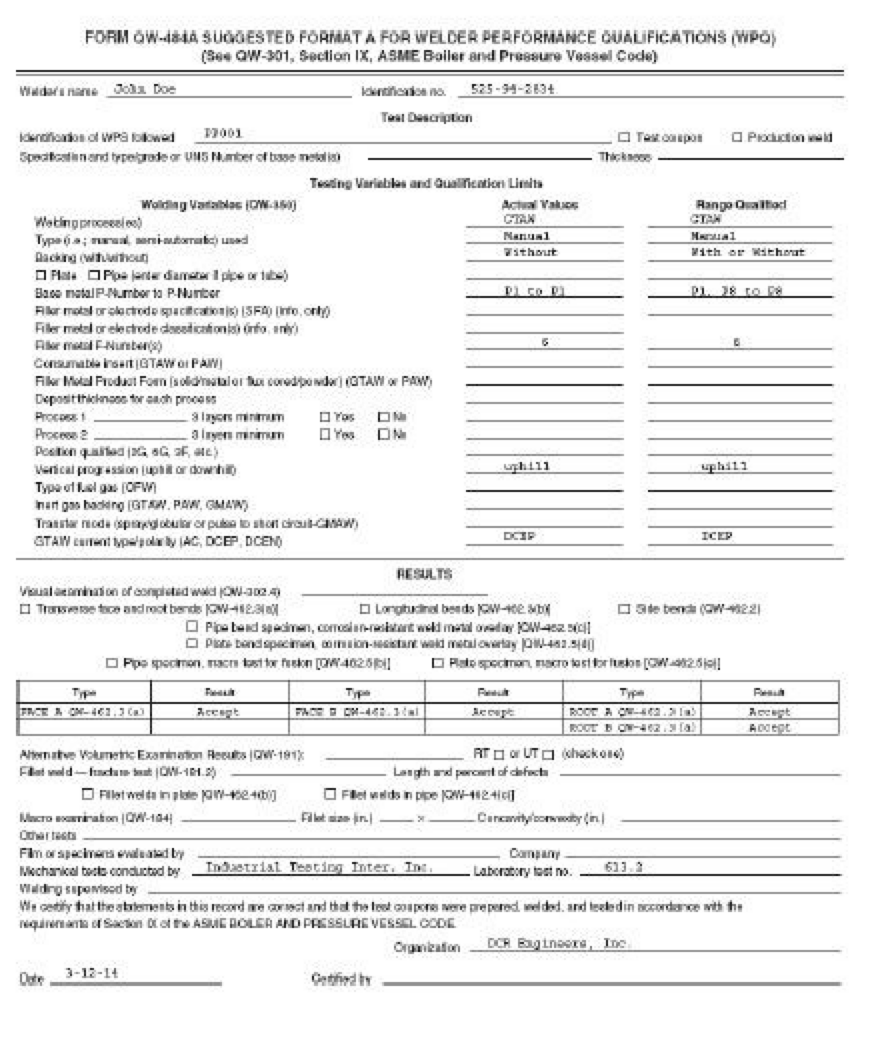

Welding Performance Qualification

Welder performance qualification tests are intended to determine the ability of a welder to deposit sound weld using qualified welding procedure specification

Variables:

- Welding process

- Filler metal

- Position

- Joint details

- Thickness

- Technique

Duration of Qualification:

Inactivity of 6 months requires re-qualification (as per ASME IX)