Abstract:

In a thermal power plant, the maintenance managers strive to improve the reliability of their equipment by proper maintenance to reduce downtime. This is a big challenge, particularly when operating conditions are harsh. The boiler unit in a thermal power plant is a classic example of this type of challenge. Running the boiler unit smoothly without downtime is the ultimate objective. However, most of its accessories either demand frequent repair or replacement due to high operating temperature and wear conditions. This white paper introduces Henkel’s innovative, sustainable solution LOCTITE®PC 7000, which is primarily developed to protect parts and boiler accessories against harsh operating conditions. The paper also compares technological advantages over the conventional ‘Hardfacing’ technique used to protect coal burners.

The mentioned case study also highlights that the coal burner tips application with LOCTITE® PC 7000 results in 2X life of the coal burner tip over the conventional method. This improved life of burner tip results in a huge reduction of downtime cost which ultimately helps to increase the overall productivity and efficiency of a thermal power plant. Further, this metal mesh reinforced ceramic coating technology is extended to application areas such as furnaces, boilers, kilns, reactors and several material handling inlets and outlets channels.

About Coal Burner Erosion:

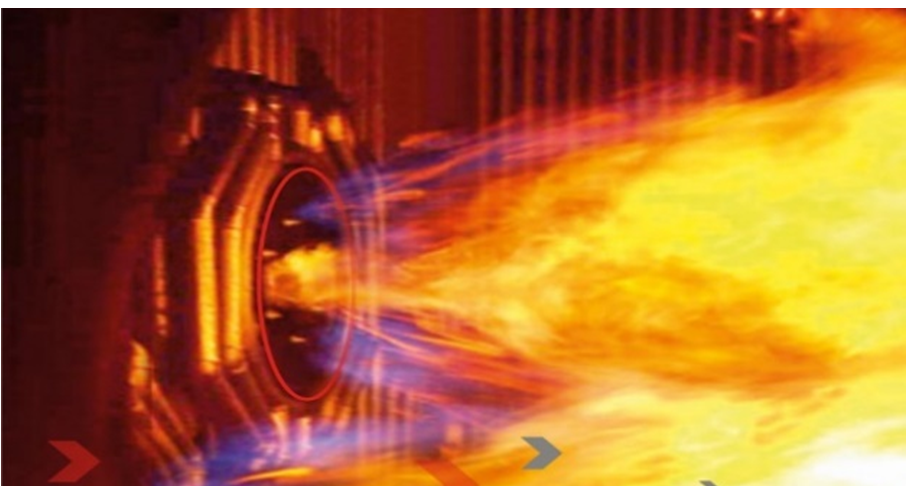

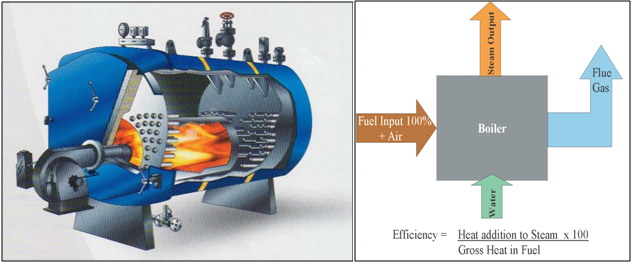

A pulverized coal-fired boiler unit generates thermal energy using pulverized coal particles as fuel and that is blown into the firebox. And this fireball is responsible for generating the steam and sending it to the power turbine for energy generation.

Most boilers use pulverized coal as the fuel which is injected through the burner at a very high velocity and at the tip of the burner, this pressured fuel is fired at an elevated temperature which is more than 1100°C. Under this harsh operating condition, this highly abrasive pulverized coal causes severe damage to the burner tip and it results in material loss and affects the operational performance in the long run. Beyond a certain point, adjusting the firing angle by tilting the burner tip does not help to maintain the fireball at the center. As a result of this, it may cause to overheat the boiler tubes and the uncontrolled flow of pulverized coal results in incomplete combustion. This means that to achieve the best efficiency, correct firing needs to be ensured by keeping the burner tip condition in its best shape.

The most common expectation from any boiler maintenance team is that the complete maintenance happens during the shutdown; as once the unit starts, it gets very difficult to repair and replace. Not only the front tip but also, the bend, pipes and nozzle box are subjected to an extremely high level of fine particle erosion.

Depending on the size and capacity of the boiler unit the number of firing burners will vary. For example, 500 MW boilers will have more burners as compared to 135 MW units. More the number of burners, the higher is the repair (36 burners X 2 times/year). This wear factor is also largely dependent on the quality of coal because different places of the world have different grades of coal with varied ash content in it. The average life of such a hard-faced burner is projected around 6 to 8 months.

Effect of Wear on Boiler Operational Performance:

- Frequent repair and replacement cost

- Lowering combustion efficiency

- Increases NOx & SOx percentages in the flue gases

- Frequent monitoring and control on burner

- Higher maintenance cost

Maintenance managers from the thermal power plant industry are commonly using conventional repair methods such as ‘hardfacing’ to prevent the above loss.

Repair with Hardfacing material:

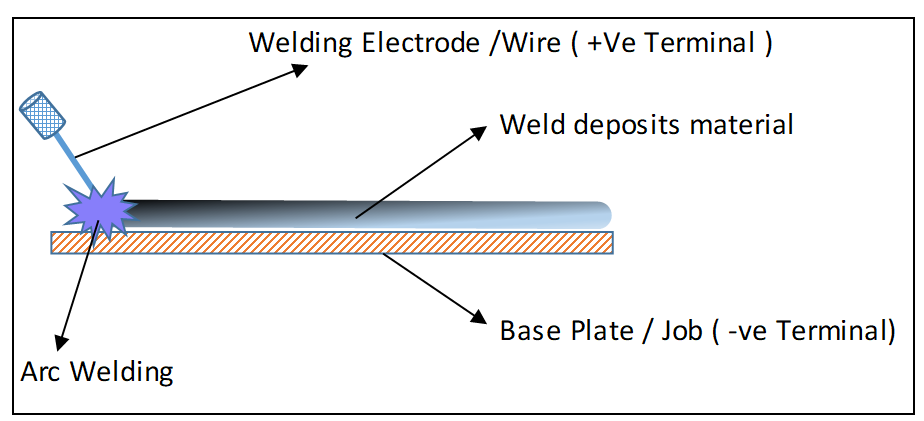

Hardfacing is also known as the weld overlay process, which is an economical method of depositing wear-resistant surfaces on metal components in single or multiple layers to extend service life. In this process, welding rods or welding wires of different metal compositions or alloys are selected and fused with the heat produced by an electric arc produced by applying voltage.

Need of innovation: Current hardfacing methods have certain limitations such as being prone to corrosion, adding extra weight to the equipment, skilled labour requirements and the involvement of hazardous welding or metal fusing processes. These limitations evolve areas of improvement and indicate the necessity to offer an innovative solution. Henkel’s innovation is made to fill the white spot. Hardfacing technology is widely used by maintenance managers to address issues like wear, leakages, surface rebuilding etc. The principle of hardfacing is iron-base alloys with manganese or chromium, molybdenum, tungsten, or titanium are fused on the metal surface to produce desired hardness. In manganese steel alloys, hardfacing wear resistance is developed because of the presence of chromium carbide particles. Some alloy compositions have tungsten carbide particles incorporated to further improve wear resistance. Hardfacing requires skilled welders to execute the job properly. Any deviation in the application procedure will result in weld defects like distortions, craters, cracks, or damage to the base plate with excessive heat. An average skilled welder can deposit manually approximately 2 lb./hr. Also, an investment in welding equipment is needed based on the automation level. As this is a completely electrically operated process, it consumes electrical energy of approximately 26KW/hr. This also varies based on the type and size of the electrode used. Proper ventilation and/or exhaust are required as high amount of fumes are produced during welding.

New Innovation of metal mesh reinforced Ceramic Composite called Loctite PC 7000:

This new innovation LOCTITE® PC 7000 is a unique three-component, rapid setting coating system which consists of silica-based binder, diluent, and high alumina content filler system. This unique 100% water-based system is designed to be set up at room temperature and develops a good compressive strength of 15 MPa within 24 hrs. Post curing at 100°C, the strength increases by several folds to 50 MPa so that coated assembly can go into service. The optimum performance is further enhanced with additional post-cure which can be achieved through in situ process heat.

The other key feature of this ceramic composite LOCTITE®PC 7000 is its strong adhesion to concrete, ceramic, refractory bricks with minimum surface preparation. The adhesion test was conducted by ASTM D2541 using a dolly pull tester on concrete as shown in Figure 6 below. The test yields the pull strength of 3MPa with concrete failure.

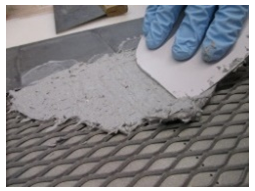

LOCTITE® PC 7000 also provides strong adhesion to metal by passivating the metal surface forming nanolayer coating at the metal interface. However, to withstand harsh operating conditions of high impact and higher abrasion, a higher coating thickness of 3 to 5 mm with a wire mesh, commonly known as the expanded mesh, is recommended which enhances adhesion and reinforcement as shown in Figure 7.

Upon mixing the three components together, it forms a pasty compound that can easily be applied to the substrate using a trowel or spatula as shown in Figure 7.

Unlike other water-based cementitious binder systems, this unique ceramic composite LOCTITE® PC 7000 exhibits very low shrinkage due to an optimum binder to filler ratio. The product forms a crack-free hard film under room temperature curing even when applied to a material having a thickness of 3 to 5 mm.

The shrinkage of this composite LOCTITE® PC 7000 was tested under various cure conditions to ensure that the coating integrity and adhesion are not sacrificed during its service life. As shown in Figure 8, LOCTITE® PC 7000 exhibits very low shrinkage even when subjected to temperatures up to 1200°C.

| Firing Temperature condition °C/hr | 110/24 | 800/5 | 1200/5 |

| Bulk Density-g/cc | 2.6 | 2.61 | 2.73 |

| Cold Crushing strength- MPa | 57.3 | 62.3 | 83 |

| Linear change in % post firing | -0.58 | -0.39 | -1.3 |

Figure 8: Linear shrinkage under different cure condition

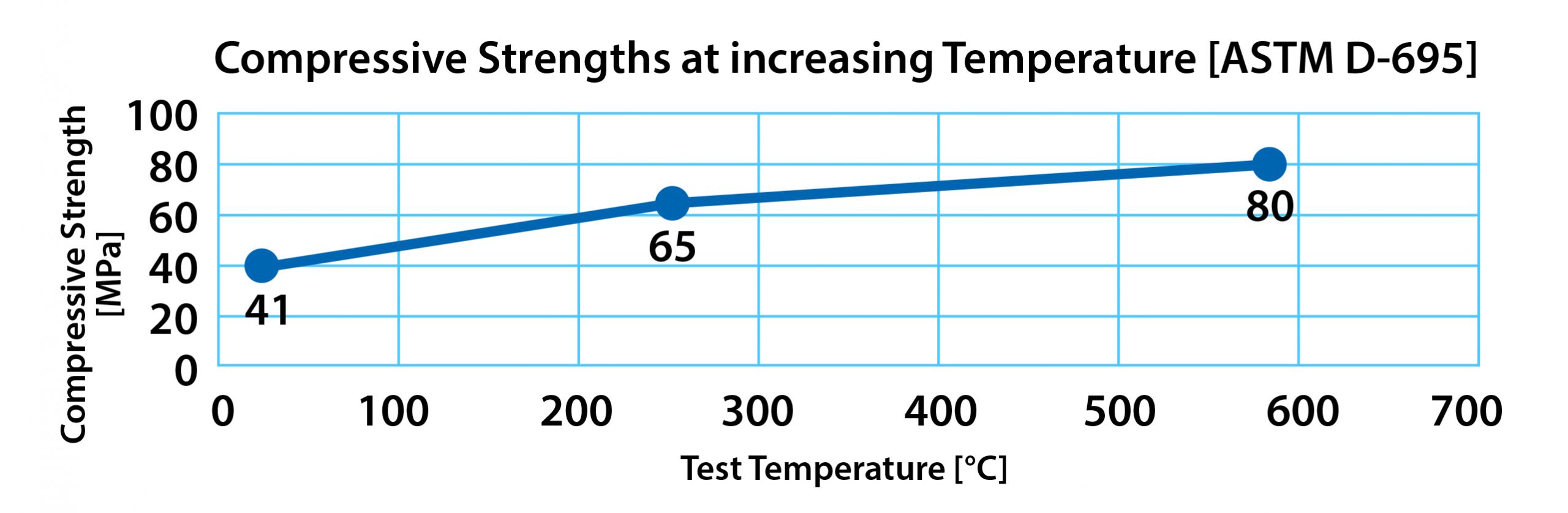

As shown in the Graph Figure 9 below, the compressive strength increases significantly with additional heat exposure due to increasing densification of the continuous ceramic matrix.

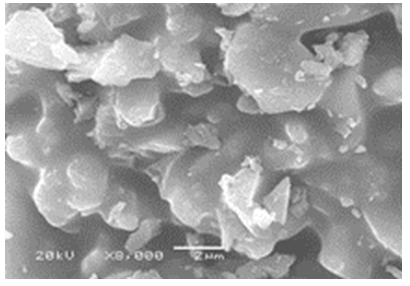

The scanning electron microscopy was conducted to understand the grain structure of the 800°C heat aged sample. SEM micrograph of 800°C aged LOCTITE® PC 7000 sample in Figure 10 shows continuous fused silica-alumina matrix with less porosity which is necessary to achieve high strength and excellent abrasion resistance.

Several key performance characteristics like heat resistance and abrasion resistance were tested internally to verify the suitability of this product LOCTITE® PC 7000 for coal burner tip application before proceeding for customer trial and validation.

The gas jet erosion test method (ASTM G-65) was used to assess high-temperature wear characteristics compared to conventional methods which are used in the industry. LOCTITE® PC 7000 ceramic composite and other conventional materials were tested at 800°C under continuous impingement of alumina powder for 15 minutes at 45° and 90° as per the standard. As shown in the graph Figure 11 below LOCTITE® PC 7000 ceramic composite clearly demonstrates the least weight loss compared to conventional materials.

The service temperature limit of PC 7000 was determined by the linear shrinkage method in accordance with DIN EN ISO 1927-1. The moulded specimen of 160 x 40 x 40 mm blocks was subjected to different temperatures and weight loss before and after firing was taken to calculate shrinkage. As shown in Figure 12, LOCTITE® PC 7000 was found to be suitable up to 1200°C based on acceptable criteria of less than 2% shrinkage and also found without any cracks.

| Firing Temperature condition °C/hr | 110/24 | 800/5 | 1200/5 |

| Bulk Density-g/cc | 2.6 | 2.61 | 2.73 |

| Cold Crushing strength- MPa | 57.3 | 62.3 | 83 |

| Linear change in % post firing | -0.58 | -0.39 | -1.3 |

Figure 12: Service temperature determination

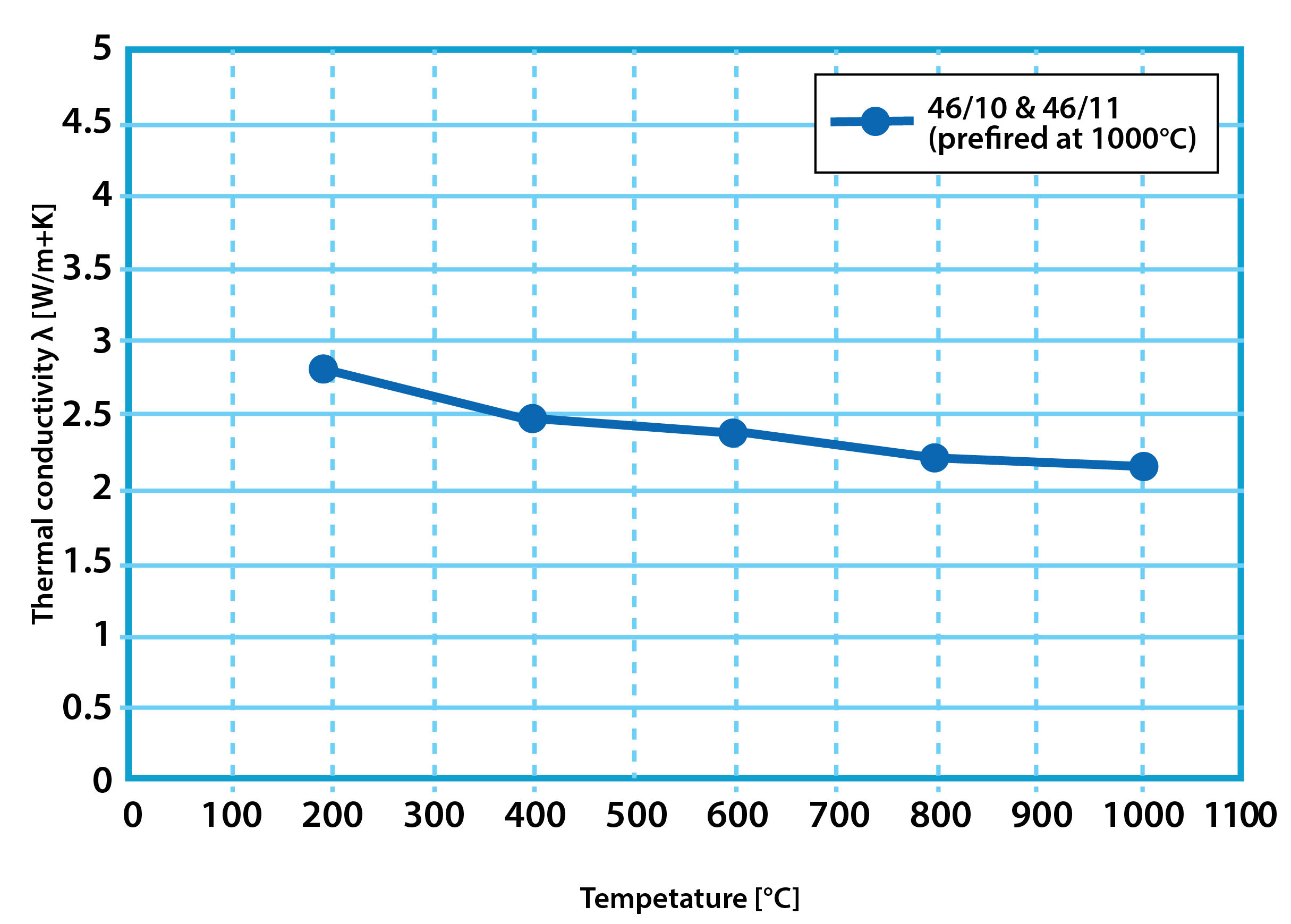

Thermal conductivity of LOCTITE® PC 7000 was also tested by EN 993-15 standards over temperature range for 200°C to 1000°C as shown in Figure 13. Due to high alumina content, LOCTITE® PC 7000 has a very good thermal conductivity of > 2.5 W/m°K and it remains fairly high at about 2.15 W/m°K even at 1000°C.

LOCTITE®PC 7000 is a unique, cold curing compound which offers many advantages and is a suitable solution for the protection of key boiler parts like coal burner tips to protect it against harsh conditions.

Key advantages:

- Sustainable formula

- Easy to apply

- No skilled labour needed

- Rapid installation

- In-situ repair

- High compressive strength and adhesion

- Excellent wear resistance

- Excellent temperature resistance

- Good impact strength

- Good thermal conductivity

Field testing & validation to evaluate the performance in harsh conditions:

A 250MW power plant in India was maintaining the boiler tip with frequent hardfacing welding material. However, it was replaced in every capital shutdown and the burner tips were repaired with a huge investment of scaffolding structure.

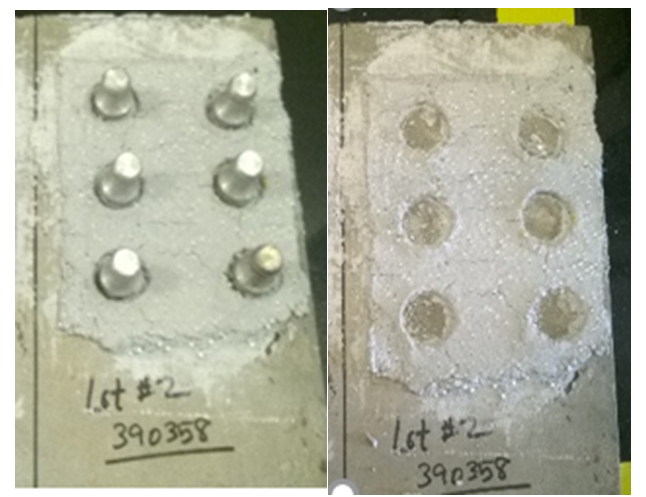

When the boiler maintenance team found out about LOCTITE® PC 7000, they wanted to see the actual performance of one of their boiler units. The team found product mixing, metallic mesh reinforcement and product application with a spatula very easy as compared to hardfacing. After lighting the boiler, close observation was made at regular intervals for fireball location and the coating thickness was inspected during every short shutdown period.

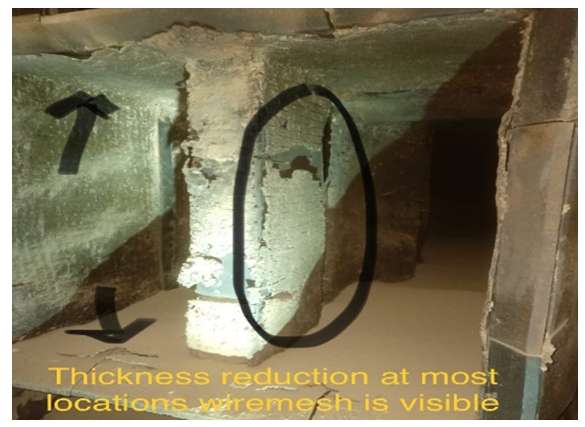

As shown in Figure 16, when the inspection was carried out after 13 months of PC 7000 application, coating existed on most of the areas. However, in the earlier case of hardfacing, the burner tip was fully damaged within 6-8 months of the application period. When this unit was fully equipped with this new innovation, the team also observed that there was a significant reduction in the scrap cost of the burner. Monitoring the level of unburnt coal particles in the ash pit, and reduction in the SOx & NOx gases due to incomplete combustion can be the future study scope for the boiler experts in order to quantify the increase in the overall productivity of the plant.

Result : The burner life is increased from 6- 8 months to 13 months with the use of sustainable LOCTITE® PC 7000.

Summary:

This white paper demonstrates many advantages of using sustainable, greener LOCTITE® PC 7000, a three-part silica-based composite system, over conventional wear-resistant materials. The lab test tribology testing and actual field trial on the boiler part, clearly demonstrate that LOCTITE® PC 7000 showed outstanding performance at elevated temperature and high abrasion conditions, which ultimately increased the life of the coal burner and various boiler accessories.

Jayesh Shah & Nilesh Adkar-Henkel Adhesive Technologies India Pvt Ltd. Pune, Maharashtra, India.

angel stefano

July 21, 2021 at 11:01 amexcelente informacion y presentacion de la mejora