Abstract

In thermal power plants, maintenance experts always strive for “Asset Integrity” which means right from the big giant turbine machine to the tiniest of fastener of a condenser. And it should perform efficiently without failure throughout its life cycle. If we talk about big critical equipment such as a Turbine, Boiler, Condenser and Pump, a very lengthy and detailed maintenance plan and worksheets are in place that are even followed rigorously. However, on many instances’ fasteners used for easy assembly & disassembly of these critical equipment are often neglected. A loose fastener may lead to safety issues and be responsible for huge downtime of the plant as well as a seized (jammed) fastener can equally be responsible for longer maintenance time and affect the integrity of assets. This article introduces new generation, metal-free, anti-seize compound that is suitable on a wide range of applications and materials.

Assembly & disassembly of fasteners:

The objective behind using various sizes of fasteners on different equipment is to enable easy assembly disassembly. In another word, open & close only on demand. There might be millions of bolts used in a thermal power plant, however, out of that, only a couple of thousands are reusable due to following main reasons:

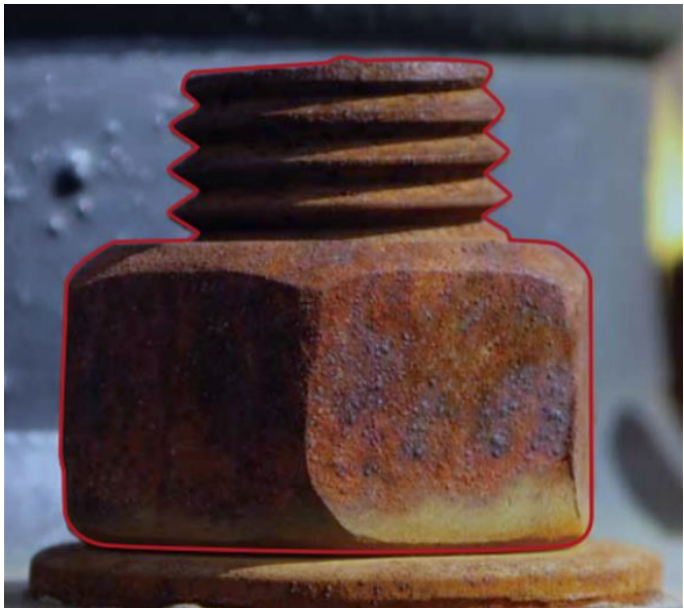

- Corrosion – environmental or harsh chemical exposure

- Seizure – elevated temperature

- Galling – friction/ heavy load

- Tampering of threads (to avoid loosening)

In order to achieve complete asset integrity, it is important to address all of the above factors that directly affect the life cycle of equipment, longer mean-time-to-maintenance, downtime cost and overall productivity of the plant. So, in order to keep the integrity of a fastener in all the harsh industrial environments, a proactive layer is necessary that covers the fasteners and easily facilitates assembly and disassembly when it is necessary.

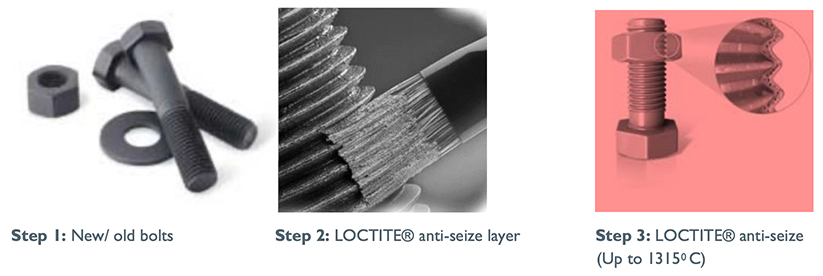

There are several types of Anti-Seize compounds used frequently within applications of high-temperatures and high-pressure loads where environmental exposure may accelerate potential seizure of components and fasteners. Anti- seize lubricating compounds are generally applied during assembly, and once again during reassembly after maintenance procedures.

LOCTITE® anti-seize compounds are a group of premium quality lubricants, developed to protect metal parts from rust, corrosion, galling, and seizing. They ease assembly and disassembly of slip-fit, press-fit, and threaded joints while reducing friction and wear on critical operating equipment. Formulated for severe industrial environments, these products protect against elevated temperatures, heavy loads, chemicals, pounding, and vibration.

Proper clamp load is an essential part of any bolted assembly for trouble-free operations. Torquing either a nut or bolt creates the clamp load. LOCTITE® anti-seize lubricant used on a bolt helps to develop greater clamp load for the same torque compared to an unlubricated bolt. An additional benefit is greater uniformity in clamp load among a series of bolts.

The relationship between torque and clamp load is expressed in the following equation:

T = KFD

Where:

T = Torque (in-lb., ft-lb, N-m)

F = Clamp Load (lb., N)

D = Nominal diameter of bolt (in, ft, m)

K = Torque coefficient or nut factor, determined experimentally

K factors can be obtained on Grade 8, 1⁄2″ steel bolts and grade 5 nuts by a test procedure which measures torque tension properties. Typically, the lubricant is applied to the bolt threads, and both faces of the washer.

Why metal-free (new generation) anti-seize is preferred?

General purpose anti-seizes used in the power plant are metal based like Copper, Nickle, Aluminum, Zinc etc., containing heavy metals. The dispersal of heavy metals, including lead, into the environment where contamination of soil and water supplies can occur is a growing concern for all types of industries.

Many countries have now adapted strict regulations and expect industries to behave more sustainably. Technically, nickel and copper base anti-seizes can be counter effective by causing corrosion when used on stainless steel, brass, and bronze metal.

That is why maintenance managers prefer to use metal free anti-seize, phasing out metallic contaminants.

Impurities vs Corrosion:

Very often technicians incorrectly believe that the same metal-based anti-seize they are familiar with can be used in every circumstance. Maintenance staff are not always properly trained to understand which anti-seize is appropriate for particular applications, nor why the right choice is important. But there is a high cost to the business for making an incorrect choice.

If incorrect metal-filled anti-seize lubricants are used on machinery, causing corrosion, the parts must be replaced. This can cause unscheduled shutdowns, meaning that profits are lost while the machines are down, and further costs the industry by requiring parts to be replaced with increased frequency, thereby decreased (MTBF) Mean Time Between

Failures. Corroded and rusty machine parts are also an increased Health & Safety risk, as greater force needs to be applied to loosen joints; and seizing, vibration and other inefficient operating difficulties can be encountered.

“There is a high cost to the business for making an incorrect anti-seize choice”

NEW GENERATION – LOCTITE® LB 8009TM (HEAVY DUTY METAL FREE ANTI-SEIZE):

Characteristics:

LOCTITE® LB 8009TM is a graphite/calcium fluoride formulation, which is metal-free, that means it is free from lead, copper, sulfur, and their compounds. It contains no free metals and is compatible with stainless steel and other nickel alloys. Typical applications of this product include bolts, screws, studs, pipe joints, nuts, plugs, bushings, extruding and forming dies, heat exchangers, shear blades, metal bending, mechanical packings etc. It is used in chemical plants, oil refineries, power plants, paper mills, steel mills and foundries, synthetic fiber plants, ship and aerospace manufacturing and service etc. This product is typically used in applications with an operating range of -29 °C to +1315 °C. It has an NLGI Grade of 1.

- Resistant to extremely elevated temperatures up to +1,315°C

- Unique brush top

- It has an NLGI grade of 1

- Metal-free

- Outstanding lubrication for all metals including stainless steel, aluminium, and soft metals.

Performance Advantages

✓ High resistance to galling, corrosion, and seizure

✓ Resistant to acids, ammonia, acetylene, and other corrosive chemicals ✓ Excellent lubrication to allow easy disassembly

✓ High operating temperature ranges

✓ Easy to apply through a range of application methods

Suitable for a broad range of metals on various equipments in power plant. These problems, including the need to comply with changing legislation, can be avoided by simply switching to the use of a metal free anti-seize lubricant product.

A high quality metal free anti-seize, such as those manufactured by Loctite, can also confer other benefits with its use. In addition to being competitively priced, Loctite’s range of metal free anti-seize products reduce wear and tear on machinery by using graphite which acts more effectively to evenly lubricate than metal-based products, thus lowering maintenance costs.

Loctite Heavy Duty Anti-Seize is widely used in mining, quarrying, and manufacturing plants, particularly in oil and gas where copper-based anti-seize use is prohibited. It has a reputation for quality and affordability and is available in both liquid and stick forms. A food grade metal free anti-seize is also available and beneficial to the food and beverage industry. Risks are reduced for workers, who are consequently not exposed to heavy metals, nor is the environment exposed to heavy metal pollution.

Loctite’s Heavy Duty Anti-Seize functions on all metals including galvanized iron, stainless steel, brass, aluminium and soft metals between -30 °C and +1315°C. Loctite’s Heavy Duty Anti-Seize has been formulated to resist higher temperatures than most other anti-seize products on the market. Loctite’s Heavy Duty Anti-Seize is also non-reactive with the catalyst used in petroleum refineries: traces of copper from metal based anti-seize products can theoretically contaminate and deactivate the catalyst used in these operations.

Conclusion:

Fasteners play a key role in the asset’s integrity. While selecting the correct lubricating anti-seize, it is important to select a metal free version of anti-seize compound that is suitable on a wide variety of applications and materials while avoiding soil & water contamination in the plant.

Acknowledgment

Thanks to experts for their valuable contributions & inputs to this article.

Matthew Miner – Lead Application Engineer North America,

Krishna Saraswat – Application Engineer India

Dilara Sacligil – Application Engineer Turkey Mirjana Fulir – Head of Market & Customer activation -EEIMEA

References

Henkel technical information reports.

All marks are trademarks and/or registered trademarks of Henkel and its affiliates in the U.S., Germany and elsewhere. ©2021 Henkel Corporation. All rights reserved DSGN0018478 (12/2021)

Nilesh Adkar – Application Engineering Manager (India/Turkey/GCC), Henkel Adhesive Technologies India Pvt Ltd. Pune, Maharashtra, India.