Name: Yohan Engineer

IB Turbo Pvt. Ltd.

President (Operations)

Pressure Reducing Turbines for Incidental Power Generation

There are 2 types of steam turbines in operation within industrial plants- Power plants and Industrial CHP. Power plants suffer from poor cycle efficiency and the resultant power cost is between Rs 5-7/unit for power plants in the 3-15 MW range. Whereas power is the only output from the power plant, combined heat and power plants have higher energetic efficiency.

The steam required for the process is generated by a boiler and passed through a steam turbine to generate electricity and the heat is subsequently used by the process. These include textile mills, paper mills, rice, solvent, refineries, chemical plants, sugar and distilleries and are gaining increasing prominence today. When properly configured and designed, the turbine can meet 100% of the electrical needs of some plants. IBL offer their Magnum single drum boiler and Multiple impulse & reaction turbines for CHP applications and has over 330 installations. These plants are usually between 12 Ton/Hr to 100 Ton/Hr, with a working pressure of 51 Kg/cm2 and 69 Kg/cm2 and power from 800 KW up to 10 MW.

Despite their superior economics, back-pressure turbines suffer from the following limitations:

- Additional investment: 4-5 times that of a low-pressure Boiler

- First-time boiler users consider it a “risk” and do not have the appetite for it

- Operational issues at Part load – below 60%

- Unsuitable for processes with large fluctuations in steam flow

- Standalone machines require continuous load management

This leads to some industries opting for low-pressure boilers for their plant steam consumption.

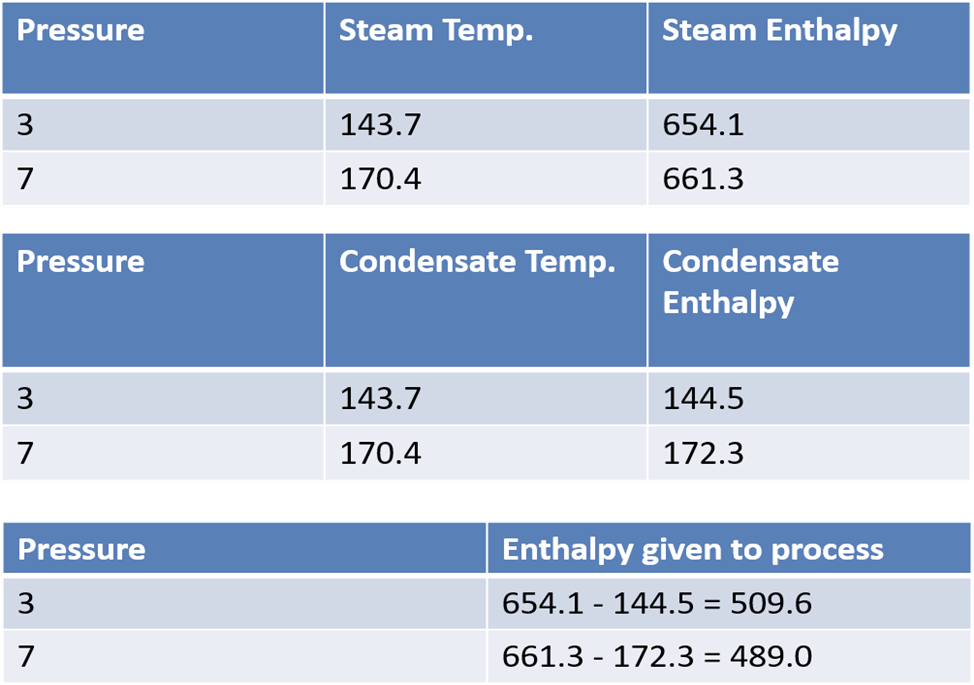

Steam tables elaborate that producing steam at the highest pressure ensures maximum dryness. Producing steam at a higher pressure does not require additional enthalpy and fuel consumption.

| Pressure | Saturation Steam Temp. | Steam Enthalpy | % Increase compared to 10Bar |

| 3 | 143.7 | 654.1 | – |

| 10 | 179.4 | 663.0 | – |

| 17 | 203.4 | 667.1 | 0.6 % |

| 21 | 213.8 | 668.2 | 0.78 % |

Steam should also be consumed at the lowest pressure. The temperature of condensate depends on the temperature of steam, which depends on the pressure of steam. E.g., condensate from 3 bar steam will have a lower Enthalpy than condensate from 7 bar steam. This can be concluded as – consuming steam at lower pressures results in reduced fuel consumption.

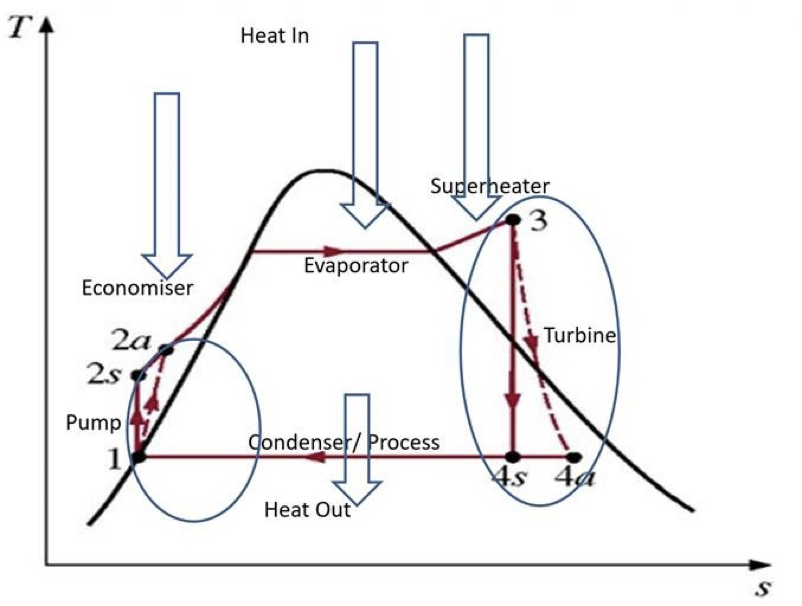

For the conversion of steam from high pressure to low pressure, it is important to understand the importance of Entropy. Entropy is a thermodynamic quantity representing the unavailability of a system’s thermal energy for conversion into mechanical work, often interpreted as the degree of disorder or randomness in the system. The entropy of an object is a measure of the amount of energy which is unavailable to do work.

For example – you can’t unscramble an egg

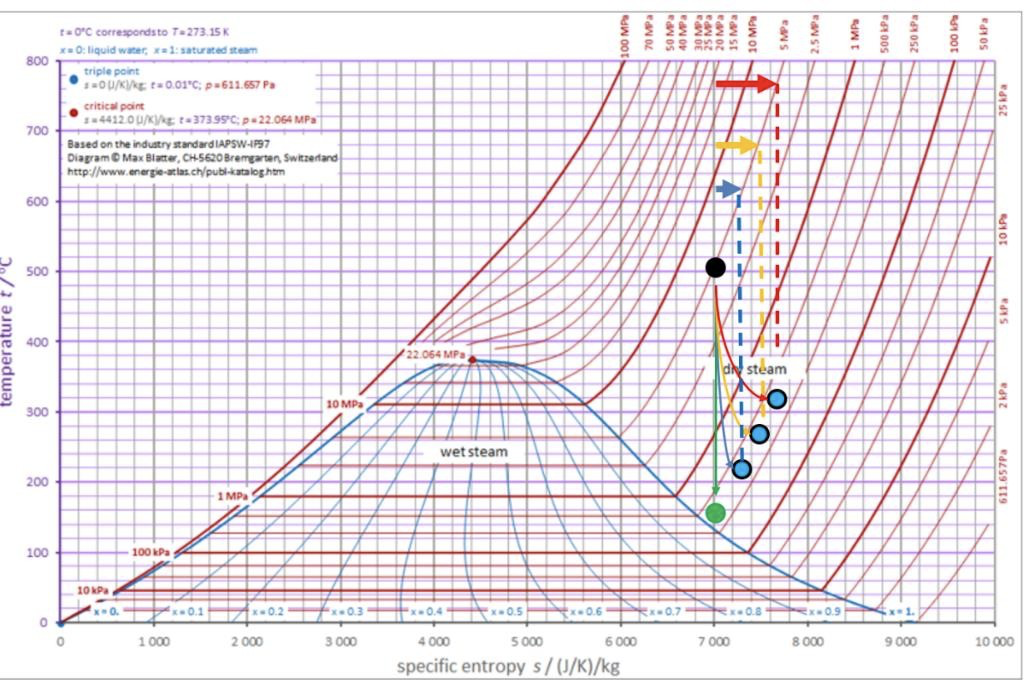

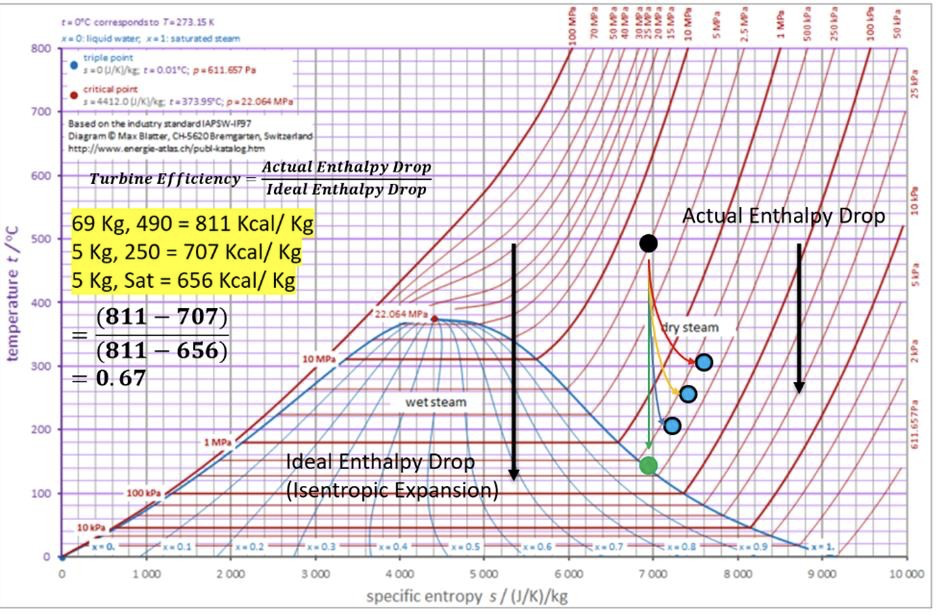

The T-s diagram or Mollier chart demonstrates the change in enthalpy and entropy during pressure reduction.

The figure below demonstrates the increase in Entropy during pressure reduction. The green line represents ideal expansion with no increase in Entropy. Redline expresses inefficient expansion with a maximum increase in Entropy.

The figure below represents the decrease in Enthalpy. The green line represents ideal expansion with complete conversion of Enthalpy. Redline expresses complete conversion of Enthalpy.

An Actual case with 63% expander efficiency is also shown.

Traditionally, process industries undertake pressure reduction using Pressure Reducing Valves (PRVs). IB Turbo’s PRT represents a novel way of recovering this lost energy.

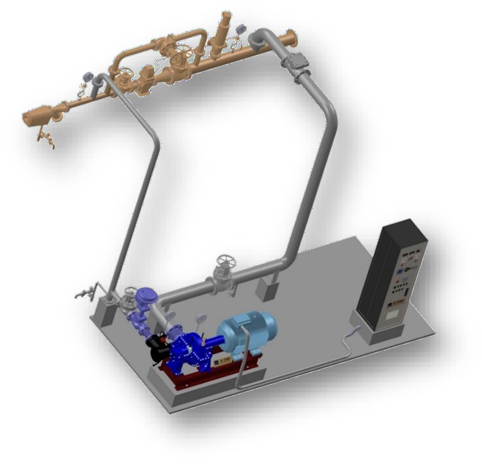

A PRT is a special-purpose turbine designed to reduce pressure while generating power at the same time.

| Pressure | Temperature | Entropy | |

| Kg/cm2a | Deg C | KJ/ K | |

| From Boiler | 10 | 184 | 6.5635 |

| Using PRV | 2 | 157 | 7.114 |

| Using PRT | 2 | 133.6 | 6.723 |

Entropy increases in the system using PRV = 7.11 – 6.56 = 0.55 KJ/K

Entropy increases in the system using PRT = 7.11 – 6.73 = 0.38 KJ/K

This means the losses in the system are far less when we use a PRT. These losses are converted into electric power generation.

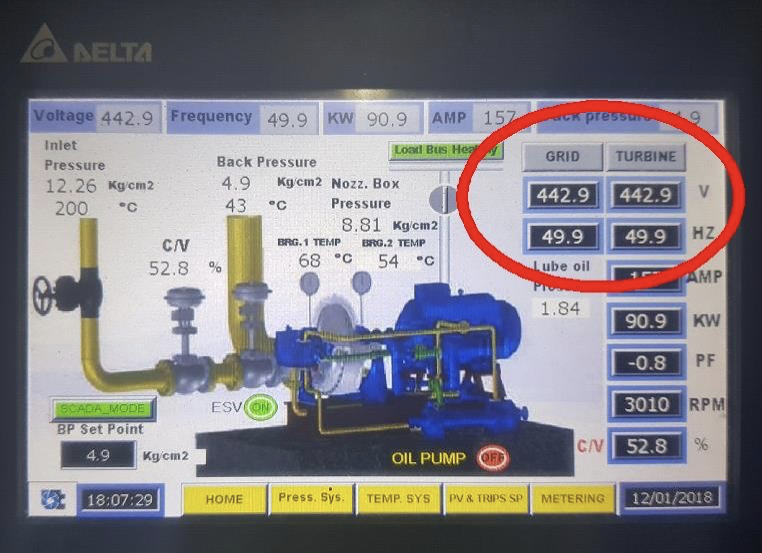

Process steam demand is maintained by a control valve using a user-defined back pressure set point.

Grid voltage and frequency are perfectly maintained by the induction generator.

The PRT is installed in parallel to the stand-by PRDS station.

All user operation is handled via a 7” / 10” touch screen HMI display. The user-friendly gadget displays turbine and grid synchronizing data in a clear, easily understandable format. The position of the steam flow control valve is also indicated on the display. The metering page quantifies daily & shift-wise power generation, savings and return on investment.

To achieve the highest possible efficiency for multiple plant configurations, IB Turbo has a range of turbine frames to provide the highest possible power generation from the customer’s steam conditions.

- PRT – 4 (3-8 TPH Flow)

- PRT – 6 (8-15 TPH Flow)

- PRT – 6SS (API 611 compliant)

- PRT – 8 (15-30 TPH Flow)

- HBPRT – 8

Referring to the limitations of high-pressure Cogen systems, PRTs have the following advantages:

- Additional Investment: 4-5 times that of a low-pressure Boiler

Only 1.2x additional investment required

- First-time boiler users consider it as a “risk” and do not have the appetite for it.

The good learning curve for process steam boiler users

- Operational issues at Part load – below 60%

Can be operated as low as 30% flow

- Unsuitable for processes with large fluctuations in steam flow

The induction generator adjusts power generation based on process steam flow. Therefore, we call it “incidental power generation”

- Standalone machines require continuous load management to balance process steam demand

PRT’s control system varies the power generation for a fixed process set point.

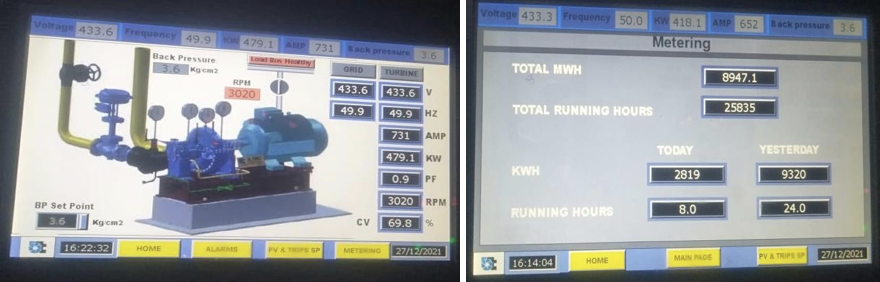

Case study – Om Shree Papertek Hyderabad – 250 TPD kraft paper plant. Steam is mainly used for drying and pulping applications. This plant has a 17 Bar 20 TPH Industrial Boilers Ltd (IBL) make Boiler. PRT -8 frame with 450 KW Induction generator supplied in 2019.

Daily power generation is more than 9000 units per day. Lifetime power generation is 8947 MWh, considering a power cost of Rs 7/unit this translates into savings of Rs 6.63 Cr over 3 years. Payback was achieved in less than 6 months. In brief, the boiler house is converted from a liability to a profit centre.

IBL has supplied 250 low-pressure boiler + PRT turbine sets.

Usually, they are in the range of:

- 6 Ton/Hr up to 20 Ton/Hr

- Boiler pressure of 10 Kg/cm2 and 21 Kg/cm2

- Power from 100 KW up to 800 KW

- Process steam pressure of 2 Kg/cm2 and up to 6 Kg/cm2

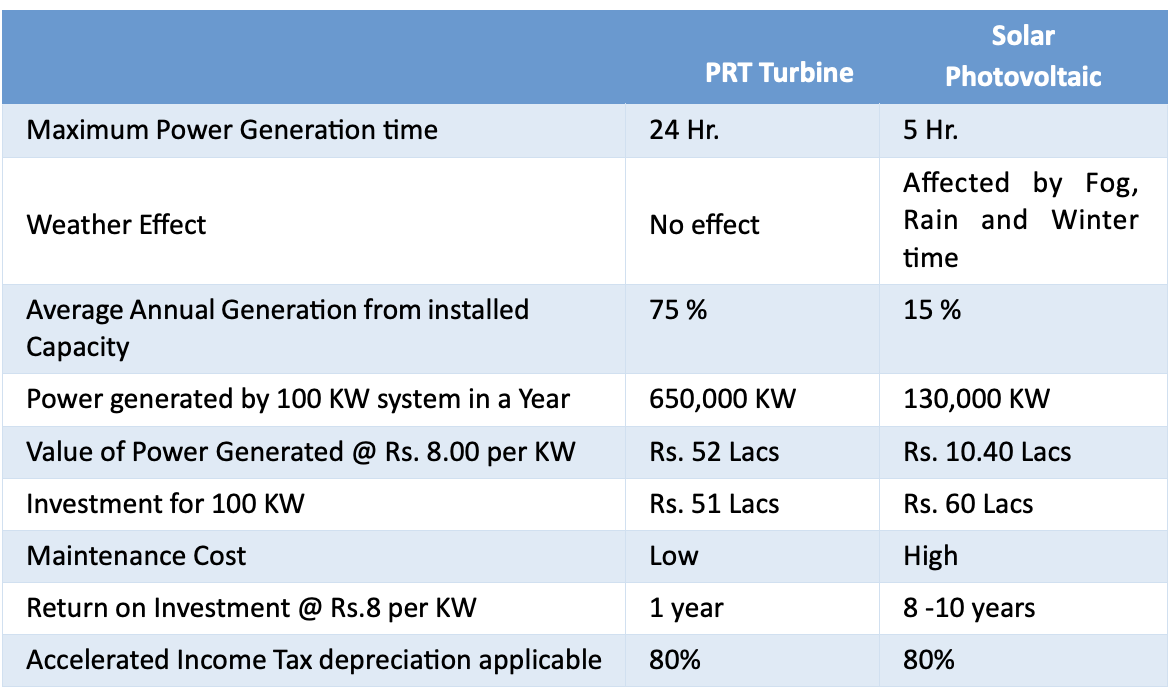

The table below elaborates on the superior economics of PRTs compared to solar PV modules.