In 2015, countries made commitments toward a more environmentally balanced future through the Sustainable Development Goals (SDGs), and now seek to expand policies for low-carbon development after the agreement reached in Paris at COP21. The year also marked a milestone in the bio-economy, as the point in time when the production of second-generation biofuels (2G) finally took off at a commercial scale. Developing countries now face a new set of market opportunities and policy dilemmas to enhance their usage of biomass, which can now be transformed into more valuable products.

Second-generation biofuels can be classified either by process type, estimated greenhouse gas (GHG) emission reductions compared to the fossil-fuel equivalent, or feedstock type. This report primarily looks at feedstock choice, which concerns fuels made from non-edible feedstocks, partially in reaction to the food versus fuel debate. Nevertheless, process improvements have been a key factor in decreasing costs for the industry and allowing market expansion.

Advanced biofuels are important tools to be considered in national policies in the coming decades. They are a renewable energy option with great potential to help de-carbonize transportation and other systems in developing countries. Advanced biofuels consequently relate to numerous SDGs and national commitments to limit climate change to tolerable levels. Their responsible development in the coming years should take into account lessons from first-generation biofuels (and other renewable energy technologies), which have received intense scrutiny in recent years. In particular, rules on trade and the sustainability aspects of advanced biofuels should be applied coherently with other regulations, both domestically and internationally.

With a considerable increase in biofuels trade since 2006, sustainability certification gradually became a new norm in the industry and a de-facto prerequisite for market access. After an intense debate on the formulation of sustainability regulations, certification, and labelling of biofuels and feedstocks, sustainability criteria for biofuels have evolved mainly through voluntary schemes compliant with legislation adopted in major markets.

While most countries discussed the pros and cons of biofuels, two approaches to sustainability in this area emerged in the period 2006 to 2015. One approach was to improve the current-generation biofuels. The second was to promote technological improvements that allowed for a broader scope of biomass to be processed into energy and biomaterials, reducing competition for food crops, which traditionally served as the main feedstock for biofuel production.

Moreover, the government is considering the creation of a National Biofuel Fund (NBF) for providing financial incentives such as subsidies and grants for new and second-generation biomass feedstocks, advanced technologies and conversion processes, and production units based on new and second-generation feedstocks. Moreover, the biofuel technologies and projects would be allowed 100 per cent foreign equity through automatic approval routes to attract Foreign Direct Investment (FDI), provided such biofuels produced are put only to domestic use.

Biofuel crops:

Dedicated energy crops represent an additional potential source of feedstock for biofuel production. Biofuel crops can be broadly classified between grassy (herbaceous or forage) and woody (tree) crops.

Perennial forage crop species are a promising source of feedstock for second-generation biofuels. Switchgrass (Panicum virgatum L.) is frequently mentioned because of its relatively low water and nutrition input and requirement costs, positive environmental impact, and adaptability to low-quality land.

Current status of biofuel production:

A large-scale blending of biodiesel with conventional diesel has not yet begun in India. Approximately, 20 biodiesel plants annually produce 140-300 million litres of biodiesel, which is mostly utilized by the informal sector locally for irrigation and electricity generation and by the automobile and transportation companies to run their experimental projects (USDA, 2010). The NBM primarily focused on the expansion of the Jatropha area in two phases. The first phase, which was the demonstration phase, included several micro-missions on Jatropha, including the promotion of its large-scale plantations in forests and wastelands, the procurement of seed and oil extraction, transesterification, blending, trade and technological research and development. The second phase of the expansion aims to make the program self-sustainable by producing enough biodiesel to meet the 20 per cent blending target. To ensure a fair price for Jatropha farmers, various state governments have offered MPP for Jatropha seeds.

Some subsidy programs and tax concessions/exemptions are also part of the government’s efforts to boost the production of feedstocks for biofuels.

Several public institutions, such as the National Oilseeds and Vegetable Oils Development Board (NOVOD), under the Ministry of Agriculture (MoA), State Biofuel Boards, State Agricultural Universities, and non-state actors, such as Non-Governmental Organizations (NGOs), self-help groups (SHGs), and co-operative societies, are also actively supporting the biofuel program in various capacities.

Biodiesel:

Biodiesel is considered an important bioenergy option for India. There is a potential to increase biodiesel production by tapping into the existing resources of Tree-borne Oilseeds (TBOs) in the country as well as by establishing new plantations. The efforts towards biodiesel production are focused on using non-edible oils obtained from Jatropha, Pongamia, and other TBOs. The emphasis has been on encouraging the use of wastelands and other unproductive lands for the cultivation of these relatively hardy ‘new’ biofuel crops. The Indian government does not want biofuel feedstock crop cultivation to compete with food crops for scarce agricultural land and water (MNRE, 2009). Government policy is also driven by the vast rural population in India, considering their needs for food security, energy access, and gainful employment. There is some concern about the definition of ‘wastelands’ in land use statistics, as informal uses, such as some grazing or less intensive dryland farming, may be taking place on these lands.

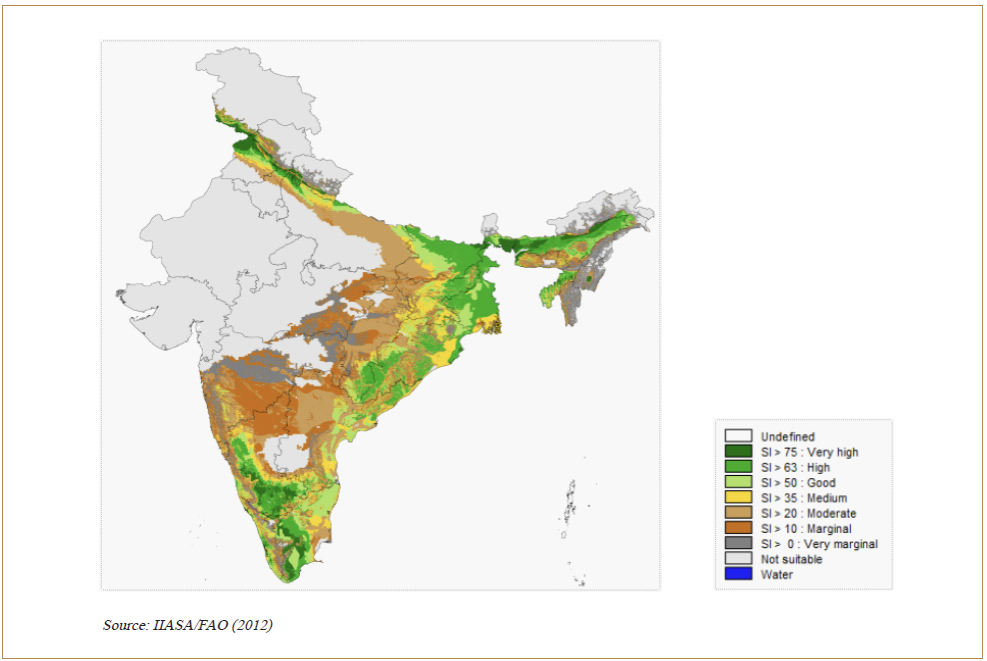

This FAO/IIASA global agro-ecological zone modelling framework (GAEZ v3.0) has been used to assess the spatial availability and suitability of culturable wastelands for Jatropha production in India. The figure presents estimates of wasteland by different suitability classes (very suitable, suitable, and moderately suitable), its potential production, and the average attainable oil yields. The total extent of culturable wasteland (excluding protected areas) is taken from district level land utilization statistics.

The Jatropha seed distribution channels are currently underdeveloped, and there is an insufficient number of processing plants in operation. Although several private companies have ventured into Jatropha cultivation and biodiesel production, their involvement is still very low. There are no specific markets for Jatropha seed supply, and hence, the middlemen play a major role in taking the seeds to the processing centres, which inflates the marketing margin. The processing industry suffers from low backward integration with the seed market and forward integration with biodiesel distribution channels. The distribution channels are almost non-existent, as most of the biofuel produced is used either by the producing companies for self-use or by certain transport companies on a trial basis. Unless the large scale use of biodiesel commences or a demand-pull from the mandatory blending of biodiesel comes, these channels will remain under-developed. Furthermore, the cost of biodiesel depends substantially on the cost of seeds and the economy of scale at which the processing plant is operating.

Second-Generation Biofuel Production in India:

Currently, the production of biofuels is limited to the so-called first-generation biofuels, comprising biodiesel from vegetable oils and bioethanol from sugar or starch-containing plants. The production of feedstocks and first-generation biofuels relies on well-known technologies, and the actual exploitation of the final products is well established. However, these biofuels have significant costs and disadvantages mainly due to the limited feedstock species suitable for first-generation conversion.

Furthermore, there is great concern about feedstock competition between the biofuel and food industries, the risks to food security, and another potential – mainly economical – impacts that the use of food crops for fuel production would have on the food industry and society in general. The discussion triggered by the 2008 global food crisis highlighted that feedstock for first-generation biofuels requires large amounts of land, water, and chemical fertilizers, with substantial environmental and economic costs and with highly uncertain outcomes for GHG mitigation. Second-generation biofuels derived from lignocellulosic feedstocks can overcome the problem of feedstock availability, enabling the use of a much broader variety of biomass sources.

Second-generation biofuels originate from agricultural residues and by-products, organic wastes, and materials derived from purposely grown energy plantations, offering a more preferable variety of woody, grassy, and waste materials as feedstock. Major national biofuel programs have been initiated to produce cost-efficient ethanol and other fuels from agricultural and forest lignocellulosic biomass in countries such as the USA and China. Although second-generation biofuels are still under technological investigation regarding conversion technologies and process operation, they are expected to meet the requirements for lower land use and much better CO2 emission reduction potential after commercialization.

Second-generation biofuels: Sustainability issues

Second-generation biofuels are novel and innovative but have their own sustainability impacts. While they are typically non-traditional commodities, higher-yielding and often non-food crops that do not compete with food markets, they may not fit neatly into traditional biofuel definitions. Nonetheless, dangers with second-generation feedstocks can include highly invasive crops that could be higher yielding than first-generation feedstocks, but can still cause issues or damage to ecosystems. Second-generation biofuels from agricultural wastes can encourage the removal of excess crop residues from the land. For example, if all crop residues can be converted to cellulosic ethanol and removal is excessive, potential impacts such as damage to soil quality and waterways could occur. Schemes such as the Roundtable on Sustainable Biomaterials address this risk by requiring that the usage of lignocellulosic material does not occur at the expense of long-term soil stability and organic matter content.

Sustainability schemes should be rigorous, but with an element of flexibility in their implementation, to allow waste material originating from a wide range of producers to be eligible. The upstream verification needs to be economically feasible to encourage their uptake in the biofuels sector.

Logistical and cost assessment of second-generation biofuel:

The general framework for the biofuel supply chain is as follows. Biomass feedstocks are first collected and processed into a bale (e.g., maize stover) or pellets (woody biomass) for easier storage and transportation.

For example, maize stover bales typically have a moisture mass fraction of 30 per cent. The bales are stored on the farm before being transported to pre-processing facilities. In the pre-processing facility, maize stover is chopped into small pieces of 2.5-5.0 cm and then further dried to a moisture content of approximately 7 per cent and crushed to 1-2 mm. Preprocessed biomass is then sent to bio-refinery facilities to be converted into drop-in 13 biofuels. The drop-in biofuels can be transported to the end-use locations for

blending.

Supply chain design and operational planning are among the greatest challenges in cellulosic biofuel. Feedstock production and logistics constitute 35 per cent or more of the total production costs of advanced biofuel, and logistics costs can make up 50-75 per cent of the feedstock costs. To facilitate the commercialization of biofuel production, it is important to investigate the optimal number and locations for bio-refinery facilities and to find the optimal allocation of feedstock and biofuel. There has been emerging literature on biofuel supply chain design.

The potential biofuel production and associated number of production plants in a region can be defined based on the current and projected availability of agricultural residues. It may be noted that the calculations are based on actual material flows and represent only a theoretical estimation. Not all types of residues are currently considered suitable for the available second-generation biofuel options. However, because using a wide range of feedstocks is the aim of further R&D, all residue types were assumed to be used for biofuel production in the future.

The number of second-generation biofuels indicated in this study could theoretically easily meet the current 20 per cent blending target across the country if all unused (i.e., after subtracting feed and other uses) residues were converted into cellulosic-ethanol. The results show that sustainable second-generation biofuel production from agricultural residues,

even when effectively used, can only provide a limited share of total transport fuels. This share might increase in the long term through technology improvements and higher conversion efficiencies.

The costs of biomass feedstock supply at biofuel production facilities strongly depend on regionally specific conditions, such as biomass potentials and density of feedstock availability related to the total area of the region, infrastructure with regard to the transport network and its utilization, and the availability of multimodal plant sites that have access to roads, rail, and/or harbours. Because there are no established markets for most of the primary agricultural residues, there is no reliable data for costs.

Typically, the complexity of logistics and transport requirements of biomass supply increase when scaling up biofuel plant sizes, e.g., with an annual biomass demand of approximately 600,000 tons/yr for a large commercial BTL plant, due to increased transport distances, and it often involves more handling and higher storage demand. Moreover, a complex land property structure and the predominance of small landholdings may increase the complexity of feedstock logistics.

Considering that the cultivation of biomass as fuel stock on agricultural land is not a feasible option in the Indian context, selling unutilized agricultural residues for bioethanol production can create additional income for farmers. Farmers cultivating marginal areas for biodiesel feedstock (e.g., Jatropha), however, do stand to benefit from the additional income they can obtain through selling oil seeds and oil cake. The major competition for lignocellulosic agricultural residues, especially those discussed in earlier Chapters of this report, comes from their use in pulp and paper manufacturing. There is further competition for these resources for farmers’ own applications at the source, such as roof thatching, fodder for cattle, household fuel and heating. There are also other minor applications where the residues are used in areas such as packaging and handicrafts.

Despite having a large supply potential for many feedstocks, particularly agricultural residues, India is struggling to ramp up the collection of feedstocks to meet the strong growth in domestic demand for bioenergy for both power sector applications and biofuel production. In the IEA projections, India looks set to become a significant importer of solid biomass for power generation, where the demand for solid biomass will reach 37 Mtoe, nearly triple current levels, requiring some 100 million tonnes of dry biomass feedstocks. While a similar order of magnitude of agricultural residues is available, the IEA concludes that it will be difficult to collect and transport a high proportion of these residues to power plants at reasonable costs.

Compared with current-generation biofuels, the new technologies demand more highly skilled workers because the quality of feedstock and process technologies is more complex for thermo-chemical or biochemical conversion technologies compared with first-generation biofuels. India has highly skilled engineers due to the country’s lengthy experience in energy industries, and the need for having skilled labour should not complicate the establishment of a second-generation biofuel industry with regard to human resources for second-generation biofuel production.

Unlike fuel-free technologies (e.g., wind and solar PV), which mainly create jobs distant from their point of application, biofuel production is more labour-intensive at the point of feedstock growth and production. For developing countries or even developed countries that seek to promote investment in rural areas, this characteristic of biofuels is of value. Important in the development context, although labour productivity is evolving through time, studies have shown that renewable energy technologies are currently more labour intensive than fossil fuel technologies.

The use of residues is bound by different constraints because biomass is taken away from the site rather than added. Using secondary residues as feedstock (e.g., bagasse, rice husks) is expected to have only a small negative impact on the environment because these residues are usually not returned to the field. The use of primary residues, however, could lead to nutrient extraction that has to be balanced with synthetic fertilisers to avoid decreasing productivity.

Agricultural systems need to maintain soil health to be sustainable in the long term. In large scale farming, however, the emphasis is generally on boosting production with management practices that include the choice of high yielding varieties combined with tillage, use of heavy machinery, fertilisers, herbicides, pesticides, and irrigation.

Compared with current-generation biofuels, the new technologies demand more highly skilled workers because the quality of feedstock and process technologies is more complex for thermo-chemical or biochemical conversion technologies compared with first-generation biofuels. India has highly skilled engineers due to the country’s lengthy experience in energy industries, and the need for having skilled labour should not complicate the establishment of a second-generation biofuel industry with regard to human resources for second-generation biofuel production.

Unlike fuel-free technologies (e.g., wind and solar PV), which mainly create jobs distant from their point of application, biofuel production is more labour-intensive at the point of feedstock growth and production. For developing countries or even developed countries that seek to promote investment in rural areas, this characteristic of biofuels is of value. Important in the development context, although labour productivity is evolving through time, studies have shown that renewable energy technologies are currently more labour intensive than fossil fuel technologies.

The use of residues is bound by different constraints because biomass is taken away from the site rather than added. Using secondary residues as feedstock (e.g., bagasse, rice husks) is expected to have only a small negative impact on the environment because these residues are usually not returned to the field. The use of primary residues, however, could lead to nutrient extraction that has to be balanced with synthetic fertilisers to avoid decreasing productivity.

Agricultural systems need to maintain soil health to be sustainable in the long term. In large scale farming, however, the emphasis is generally on boosting production with management practices that include the choice of high yielding varieties combined with tillage, use of heavy machinery, fertilisers, herbicides, pesticides, and irrigation.

Water quantity and quality are factors that determine the extent to which bioenergy can contribute to the overall energy mix. For example, in a world already facing water stress, largely due to over 70% of freshwater being consumed by the agricultural sector, bioenergy development is likely to add to this – through feedstock production and conversion processes – and hence increase the pressure.

Moreover, access to freshwater is a growing concern in rapidly developing countries such as China, India, South Africa, etc. Therefore, in countries like India, feedstock sources such as agricultural and forestry residues that do not require irrigation or additional land should be given priority, and water requirements during the biofuel production process need to be considered carefully. Extreme weather events (inundation, droughts) due to climate change might increase uncertainty in terms of available water resources (UNEP, 2009). In addition to exacerbating water scarcity, the intensification of agricultural production induced by growing non-food biomass demand and the associated application of agrochemicals may increase the risks of water pollution and related threats to human health and aquatic ecosystems.

At the same time, there are opportunities to harness bioenergy development to help increase access to water by leveraging the introduction of efficient water management techniques, increasing soil absorption capacity in dry areas, selecting appropriate crops, and providing energy for water pumping and cleaning water.

Rishikesh Deshpande, Managing Director and Project Consultant, Sustainable Biobrikets Pvt. Ltd

Vinod Kumar Garg

September 15, 2022 at 11:59 pmWant information regarding biomass as fuel for steam boiler in Faridabad, Delhi NCR

Vinod Garg

September 16, 2022 at 12:36 amBiomass Briquet