Introduction

As the world grapples with climate change’s effects, the search for more sustainable and eco-friendly energy sources has become more urgent than ever. One of the most promising alternatives is biomass, which uses organic matter such as agricultural residues, wood chips, sawdust and industrial waste to produce energy.

Biomass has been proven to be a renewable and ideal fuel source for energy systems and retrofitting existing fossil fuel systems to biomass offers a cost-effective way to reduce emissions, particularly carbon and sulphur emissions. By switching to biomass, industries can save at least 50% on fuel bills and governments may offer financial incentives and carbon credits for using renewable energy sources.

In India, some state pollution control boards have already banned oil and coal-fired boilers due to their harmful environmental impact, leading many industries to consider biomass as an alternative heating source. Retrofitting oil and gas-fired boilers to biomass is a promising measure to cut costs and reduce harmful emissions, making it a win-win solution for industries and the environment.

Retrofitting: Transforming Fossil Fuel Systems:

Retrofitting a boiler with biomass is a simple alteration work that allows one to convert an existing oil-fired or gas-fired boiler to run on biomass fuel instead. The process of retrofitting involves modifying the existing boiler and heating system to accommodate the new fuel source; and includes the installation of a biomass fuel delivery and feeding system, along with a modified combustion system in the boiler to burn biomass fuel effectively.

Besides, the retrofitting process also alters the air pollution control devices to keep the emissions within the prescribed limits. Thus, retrofitting allows industries to use biomass in their existing boilers.

Greening the Heat: The Benefits of Retrofitting Oil-Fired Boilers to Biomass:

Accounting for its benefits in terms of emission reductions and cost-saving, retrofitting in boilers is considered for a variety of reasons, including:

- Cost savings: Running a boiler on biomass reduces the fuel cost by up to 60% as biomass fuels are generally cheaper than fossil fuels like oil or gas. Retrofitting results in significant cost savings for the customer.

- Environmental concerns: Retrofitting is often considered a way to reduce the carbon footprint of the boiler and decrease greenhouse gas emissions. By upgrading the existing boiler or heating system to burn these carbon-neutral biofuels, the industries can reduce their overall emissions and earn carbon credits. These credits can be sold in carbon markets to offset the initial cost of retrofitting or used to offset emissions.

- Regulatory compliance: In some cases, local or national regulations may require shifting to biomass. For instance, CAQM has banned using any fuel other than biomass and natural gas in the NCR region. The majority of the industries in NCR have thus started shifting to biomass as it is the most cost-effective option.

- Low CAPEX: Retrofitting an existing boiler to biomass is generally more cost-effective than purchasing a new one. A new biomass boiler requires a significant capital investment while retrofitting an existing boiler involves much lower capital costs.

- Minimal Disruption: Retrofitting an existing boiler to biomass requires minimal disruption to the existing system, as the boiler and other infrastructure are already in place. This means that the retrofitting process can be completed quickly and with minimal downtime.

A Closer Look at the Retrofitting Process:

In simple words, the process of retrofitting includes swapping the oil-or-gas burner with a biomass combustor. This combustor includes fuel and air handling systems, an external furnace and a secondary combustion control mechanism for controlling the flame. The outlet of the combustor is fitted to the inlet of the boiler’s heating chamber, which carries the combusted flame into it.

This retrofitting kit computer allows the end user to customize heat by controlling the inlet air flow rate and biomass feed rate as per the requirement. With controlled combustion and appropriate consumption of biomass, the overall efficiency of the combustion chamber is significantly improved, the rate of fuel consumption is reduced and levels of unwanted emissions have been reduced abruptly.

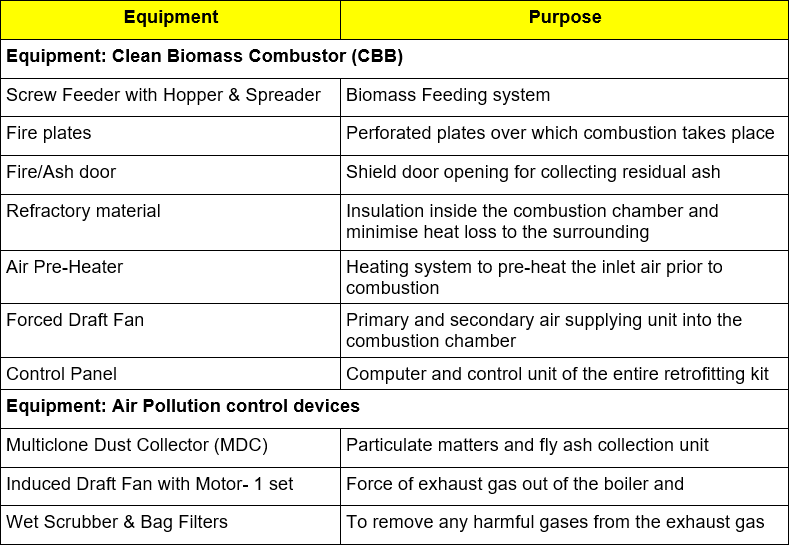

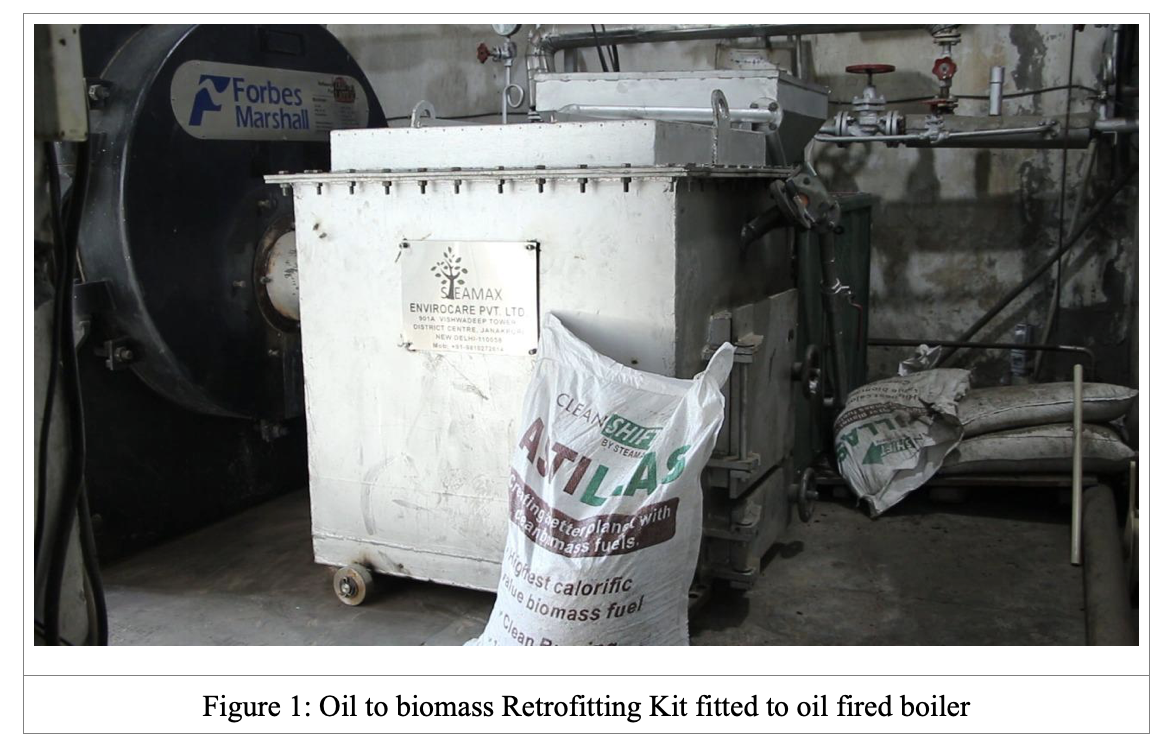

In addition, the retrofitting kit also employs modified air pollution control devices such as a multi-clone dust collection system, bag filter, scrubber, etc., to keep the emissions within the prescribed limits. The entire combustor system is mounted on a trolley, to facilitate easy movement during the periodic service and cleaning. Table 1 lists the various components involved in the OBR kit. Figure 1 portrays the pictographic view of the installed OBR kit in an oil-fired boiler.

Table 1: List of components used in retrofitting kit

Technical performance of Retrofitted Boilers:

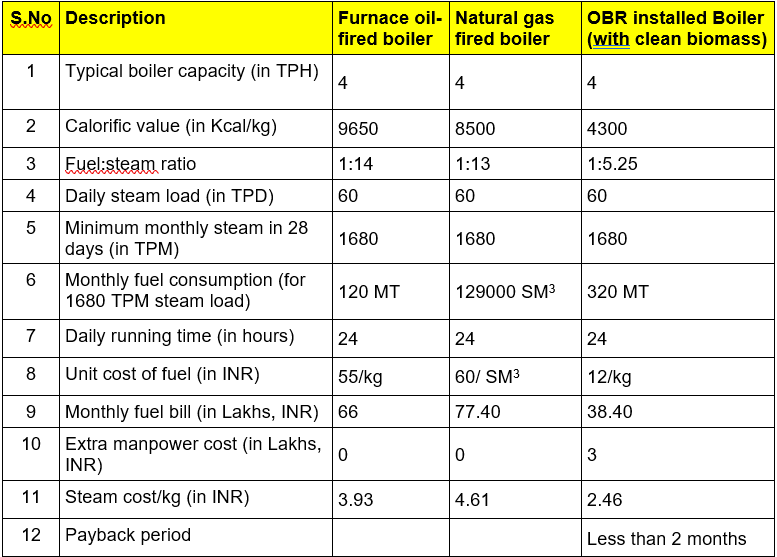

Table 2 summarises numerous technical features and performance results of biomass retrofitting kits in furnace oil and natural gas-fired boilers, operating for a boiler capacity of 4 TPH.

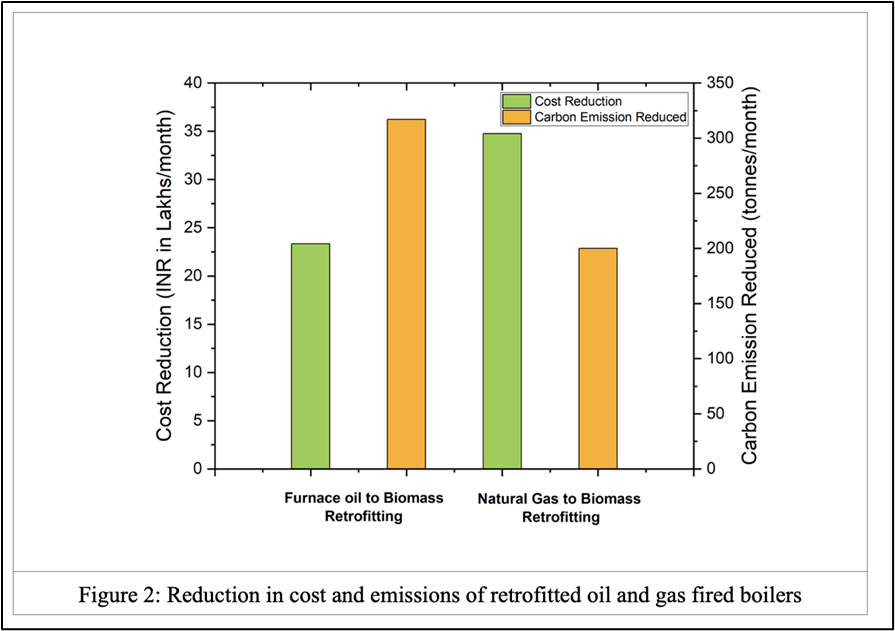

Fairly evidently, retrofitting boilers with OBR kits indeed reduces the overall operation and fuel costs of the boilers, citing the less cost of biomass fuel. Figure 2 depicts the reduction in cost and emissions upon choosing the retrofitting kit for the boiler, fired using both furnace oil and natural gas.

Table 2: Technical specifications and performance of oil-fired, gas-fired, retrofitted boilers

Simply put, introducing retrofitting kit to a boiler fired either using oil or gas helps enhance the overall rate of combustion, reducing the overall consumption of fossil fuel, cut harmful toxic gases along with carbon emissions, and the cost invested on fuels. Here, at Steamax, the primary focus is always given to using biofuels in energy systems and following the guidelines as framed by pollution control bodies and government agencies to control pollution emitted into the environment.

Author

Aditya Mahajan

(Steamx India)