Introduction

The need to abate global warming mandates the prudent usage of fossil fuels. Coal-powered thermal power plants are under pressure to perform efficiently and reduce emissions. Currently, the power generation sector alone is responsible for nearly 41% of global CO₂ emissions, with coal power being the largest contributor of nitrogen oxides (NOx), sulphur oxides (SOx), mercury (Hg) and particulate matter. Increased deployment of carbon capture, sequestration and utilization (CCUs) technologies can improve the sustainability quotient but may be insufficient to meet the climate goals set in the Paris Agreement.

Coal is still expected to provide 22% of global power and account for 68% of carbon dioxide (CO₂) emissions even in 2040. Leveraging the right technology can help thermal power plants reduce CO₂ emissions from 20% to 80%. Adoption of the latest digital technologies can help improve thermal plants’ performance by reducing the consumption of fuel, auxiliary power, consumables, and greenhouse gas emissions. Existing thermal power plants, therefore, need to be equipped with these technologies to mitigate global warming.

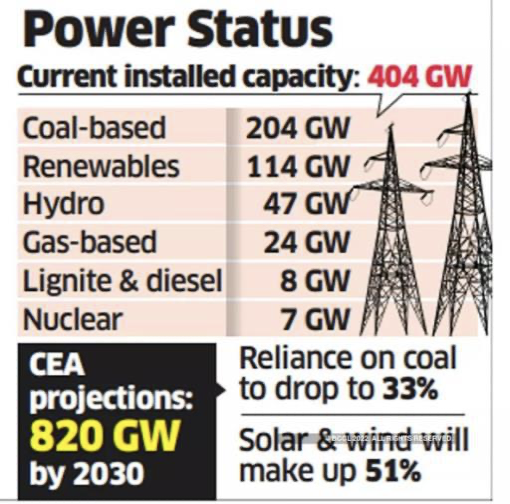

On 3rd Aug 2022, the Indian federal cabinet approved the new national emissions pledges, known as Nationally Determined Contributions (NDCs). The new NDC will commit India to reducing the emissions intensity of its GDP by 45% from its 2005 level in the next 7 years – a 10% increase over its previous 2016 pledges. India will also aim to meet half of its energy demands from renewable sources, such as solar and wind by 2030. This too is a boost over its previous target of 40%, which the government said it had achieved in December 2021. The updated NDC proposes about 50% cumulative electric power installed capacity from non-fossil fuel-based energy resources by 2030.

How to transition Coal-fired boilers to low carbon economy?

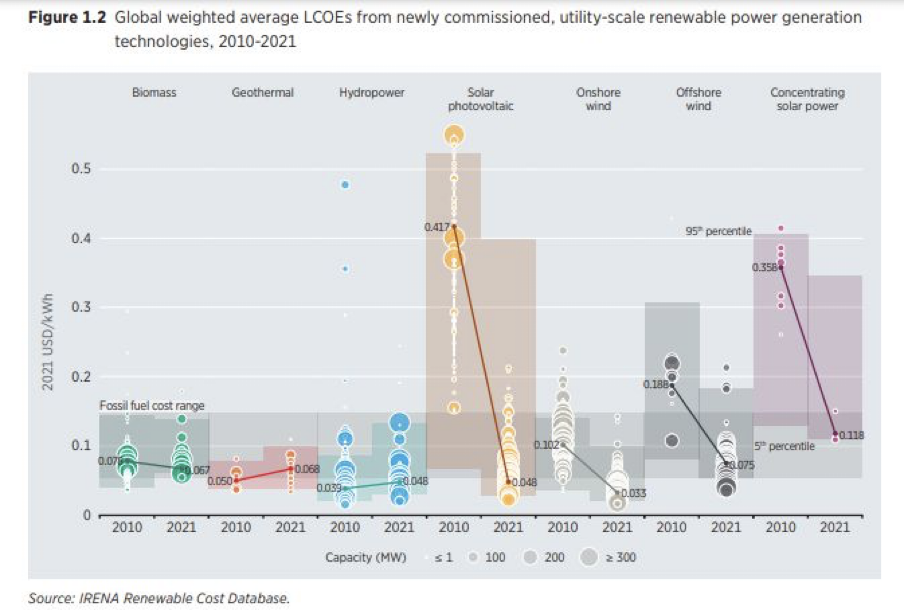

The energy dynamics will rapidly change in the next 10 years and looking at the trend of the last 10 years, this journey can be even faster. There are two fundamental ways in which coal-fired boilers can transition into a more sustainable energy:

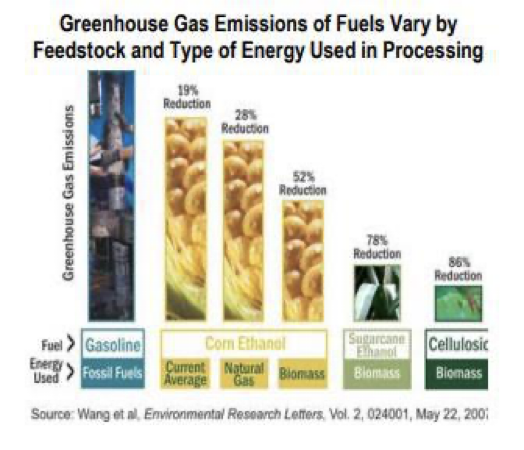

- Use of alternative fuels such as biomass, bio-gas, derived fuel, bio-diesel, etc. and this was the traditional fuel before coal was discovered.

- Deployment of Carbon Capture and Sequestration technologies, which are now beginning to get commercialized.

The term “biomass” refers to materials derived from plant matter such as trees, grasses, and agricultural crops. These materials, grown using energy from sunlight, can be renewable energy sources for fuelling many of today’s energy needs. The most common types of biomasses that are available at potentially attractive prices for energy use at federal facilities are waste wood and waste paper.

One of the most attractive and easily implemented biomass energy technologies is co-firing with coal in existing coal-fired boilers. In biomass co-firing, biomass can substitute for up to 20% of the coal used in the boiler. The biomass and coal are combusted simultaneously. Coal co-firing was successful with up to a 20% biomass mix and most of the large corporates have already started to use the bio-mass in the boilers.

Results of extensive applications have shown that the co-firing of biomass with coal has accomplished the following:

- Reduce GHG emissions,

- Significantly reduce fuel costs compared to coal or other fossil fuels (FO, NG, oil).

- Reduced emissions of NOx and SOx.

Every ton of biomass co-fired directly reduces fossil CO2 emissions by over 1 ton. Woody biomass contains virtually no sulphur, so SO2 emissions are reduced in direct proportion to the coal replacement. Biomass is a regenerative biofuel. When a fossil fuel is replaced by a biofuel, there is a net reduction in CO2 emissions. Biomass can contain considerable alkali and alkaline earth elements and chlorine, which, when mixed with other gas components derived from coal such as sulphur compounds, promotes a different array of vapour and fine particulate deposition in coal-fired boilers.

Application

Biomass co-firing can be applied at facilities with existing coal-fired boilers. The best opportunities for economically attractive co-firing are at coal-fired facilities where all or most of the following conditions apply:

- annual coal usage is significant

- local or facility-generated supplies of biomass are abundant, across the seasons

- local landfill tipping fees are high, which means it is costly to dispose of Biomass

Energy Challenges in India

Sub-critical pulverized coal (PC) technology is used in most of the coal-based thermal power plants. Coal is required in large quantities for power generation and India has abundant reserves of this fossil fuel. However, indigenous coal production hasn’t been able to meet the demands and hence significant proportion of coal is imported from overseas.

Bio Energy in India – Significance and Potential

India is a land of agriculture. It also receives regular sunshine almost throughout the year and hence suitable for the growth of energy crops as well. Consequently, there is an abundant supply of bioenergy that has the potential to complement fossil fuels, mainly coal, in generating power for the steadily increasing population in India.

As per a recent study sponsored by the Ministry of New and Renewable Energy (MNRE), the current availability of biomass in India is estimated at 750 million metric tonnes per year. The study indicated estimated surplus biomass availability at about 230 million metric tonnes per annum covering agricultural residues corresponding to a potential of about 28 GW. This apart, about 14 GW of additional power could be generated through bagasse-based cogeneration in the country’s 550 sugar mills, if these sugar mills were to adopt technically and economically optimal levels of cogeneration for extracting power from the bagasse produced by them.

The Union Ministry of New and Renewable Energy (MNRE) announced central finance assistance for projects utilising biomass like bagasse, agro-based industrial residue, crop residues, wood produced through energy plantations, weeds as well as wood waste produced in industrial operations for power generation.

Biomass has the potential to change the rural energy landscape of India in three ways:

- Electrification of nearly 75 million rural households currently un-electrified in India (25,000 MWe)

- Using bioenergy has a multiplier effect on the development of the economy as about 60% of the total plant cost is circulated back into the rural economy and could also offer employment opportunities to the rural community

- Help Reduce global warming which is already having a detrimental impact on farming due to disturbed rainfall, flooding, famine, etc.

Issues in the bioenergy sector in India:

- Lack of infrastructure to collect and process biomass resources forcing farmers to burn in fields.

- Biomass transportation and handling issues

- Changes in availability and nature of agri-waste with the season

The price for primary biomass is determined by three factors:

- The supply side factor (technically achievable biomass supply volume with associated cost)

- The demand side factor (energy demand, land demand associated with food and feed production/energy crop production/and other usages, the price of competing usage (i.e., fossil fuel price, food price)

- The policy factor (i.e., tax incentives, blending mandate)

All three factors are dynamically interlinked and require economic models for detailed assessment. The supply cost of each biomass type needs to be estimated for each local region.

Co-firing of coal and biomass Options:

Estimations show that a significant percentage of coal, up to 30%, could be replaced by biomass without any significant modifications in boilers and there would be an optimum level of biomass that can be co-fired with coal based on technical and economic limitations that need to be arrived at for each boiler by a process of optimization.

There are three major options generally available for co-firing biomass with coal. Each of them has its advantages and disadvantages. All the options have been successfully employed either on a demonstration or commercial scale. In direct co-firing, both biomass and coal are combusted in the same furnace. Both coal and biomass may use the same fuel handling and feeding systems or different ones depending on the biomass characteristics.

Direct co-firing is the cheapest and most commonly used method. Many companies are using the bio-mass as such after grinding, whereas some companies prefer to convert it into briquettes. Using the bio-mass as such is a cheaper option but has problems associated with handling and feeding and may limit the use by up to 15% in several cases. Converting into briquettes could be easier to handle but adds to the cost, Indirect co-firing utilises a gasifier to convert the solid biomass fuel into a gaseous fuel which could be co-combusted with coal in the same furnace. This method, although expensive, could be used for a broader range of biomass fuels; biomass fuels that are difficult to grind could especially be utilised through indirect co-firing.

Environmentally, the use of biomass briquettes produces much fewer greenhouse gases, specifically, 13.8% to 41.7% CO2 and NOx. There was also a reduction from 11.1% to 38.5% in SO2 emissions when compared to coal from three different leading producers, EKCC coal, Decanter coal, and Alden coal. Biomass briquettes are also fairly resistant to water degradation, an improvement over the difficulties encountered with the burning of wet coal. However, the briquettes are best used only as a supplement to coal.

Challenges in the implementation of co-firing in India

India has an ideal situation where co-firing of coal and biomass should be in optimal use. However, this has not been the case.

The big question that immediately arises is why this technology has been overlooked. Has it been tried and tested enough to be ignored? A preliminary analysis of this issue points to the following factors:

- Technical problems arising from the combustion of biomass (even if minor) in furnaces designed for coal combustion

- For higher than 15% co-firing, increased capital investment in the power plant to accommodate biomass storage, processing, and feeding

- The fluctuating availability of biomass, unpredictable prices and the absence of organised biomass market

- Utilities are concerned about issues arising from using certain biomass with high alkali or ash content.

- Utilities’ mindset to only adopt conventional pulverized coal technology – need for change management.

Also, there is a lack of support from boiler OEMs (Original Equipment Manufacturers) on co-firing and sometimes they can dissuade the co-firing citing the reliability issues in the long term. Co-firing has been in existence in India and globally for more than 20 years now and the standard operating procedures have been developed that allow the safe use of biomass-based fuels in boilers to the extent of 30% or some companies are going beyond these limits as well. It is important to set the control parameters and procedures for handling, feeding and boiler operations to achieve high boiler efficiency and reduce costs. Different types of biomass may need to be fed at different feed zones in boilers.

Government of India initiatives

The Ministry of New and Renewable Energy (MNRE) in India has taken up programmes on Biofuels through research, development and demonstration projects at various research, scientific and educational institutes, universities, national laboratories, industry, etc. India has adopted an agenda and actions based on the UN post-2015 development agenda.

Transforming our world: the 2030 Agenda for Sustainable Development, with 17 Sustainable Development Goals (SDGs) for the people, planet and prosperity reflecting the commitment to shifting onto a sustainable and resilient path. The overall aim of the Integrated Bio Energy Mission would be to contribute to achieving the GHG emissions reduction targets as agreed in the Nationally Determined Contributions at COP 21 through the progressive blending/ substitution of fossil fuels such as coal, petrol, diesel, natural gas and LPG with biomass pellets, bioethanol, biodiesel, biomethane, and similar green fuels, both for electrical and non-electrical uses.

The indicative outlay for the mission would be Rs 10,000 Crore from 2017-18 to 2021-22. The major goals of the national policy on biofuels are the development and utilization of indigenous non-food feedstocks raised on degraded or wastelands, thrust on research and development on cultivation, processing and production of biofuels and a blending mandate of 20% ethanol and bio-diesel by 2017. The objective of the biofuel programme is to support R&D and pilot plant/demonstration projects leading to the commercial development of 2nd Generation biofuels. Considerable potential exists in the country for the utilisation of materials such as municipal refuse, paddy husk, coffee husk, sawdust, bark, wood waste, etc., as fuels in boilers.

In the conventional stoker-type boiler, when agricultural waste such as paddy husk, bamboo dust, bagasse, and wood chips are to be burnt, a separate furnace is required from which the flue gas is led into the boiler. With FBC (fluidised bed consumption) boilers, there is no need for a separate furnace.

This waste can effectively be combusted in an FBC boiler without the use of supplementary fuel. Hence, it is one of the advantages of fluidised bed combustors, that they can be used for the combustion of any kind of fuel to produce heat as incinerators of combustible materials or for heat recovery proposals. Depending on the fuel characteristics, a specific combustor design is required to burn agro waste either independently or in combination either high or low-quality fuel like coal lignite, etc. in an effective way.

The advantages of fluidised bed combustion boilers are

- Ability to burn low-grade fuels

- High thermal efficiency

- Ability to burn fines

- Flexibility to burn agro-waste fuel

- Less excess air, higher Co2 in flue gas

Converting waste into Bio-gas

Biogas systems use the natural, biological process of anaerobic digestion to recycle organic waste, turning it into biogas, which is used for energy. Biogas is composed primarily of methane (50–70%) and carbon dioxide (30–50%), with trace amounts of other particulates and contaminants. Biogas can be produced from a variety of sources, including agricultural digesters, wastewater treatment facilities, and landfills. Biomass energy is derived from the combustion of organic material.

Sources of biomass include forest wood and crop residues; organic animal and municipal waste; crops cultivated to serve as biomass fuel; and by-products such as black liquor, from the pulp and paper industry. Direct combustion is the most established and commonly used technology for converting biomass to heat. Renewable natural gas (RNG) is a pipeline-quality gas that is fully interchangeable with traditional natural gas and compatible with pipeline infrastructure.

There are two principal technology platforms for producing renewable gas:

(1) Thermal gasification and

(2) Anaerobic digestion. Each platform involves the production of raw gas (i.e., biogas) that is then upgraded (i.e., impurities like carbon dioxide are removed).

Waste-to-energy is created when municipal solid waste is combusted and the heat from the resulting combustion converts water to steam, which is sent to a turbine to generate electricity and thermal heat. After this combustion process, the remaining ash from waste is processed to remove particulate matter before being trucked to a landfill.

The above graph shows the relative GHG emissions of some typical sources of biomass compared to fossil fuel.

Carbon Capture and Sequestration Technology Development

There are several developments happening to capture the carbon emission from flue gases and sequester CO2 or use the CO2 to make polymers that can replace crude oil which is conventional feedstock. A similar facility is operated by Mitsubishi Heavy Industries (MHI) Hiroshima R&D centre. This plant has boilers, dust separators, flue gas processing apparatuses, and the desulfurizing system of the wet limestone gypsum method (FGD).

The CO2 recovery system includes a rinse tower to remove sulphur oxides present in the flue gas, a cooling tower to cool the flue gas, an absorbing tower to capture CO2 by “KS-1 solvent,” a water washing tower to recover solvent components accompanying the flue gas from the CO2 absorbing tower and a regenerating tower to strip CO2 by heating the solvent absorbing CO2 with steam.

The purity of the CO2 captured from the flue gas of the coal-fired boilers is approx. 99.8%-dry, which meets the requirement of 95% or higher in purity generally required for CO2 EOR. When the concentration of sulphur oxides flowing into the CO2 recovery system is high, the accumulation of heat-stable salt, particularly sulphate, increases to cause the deterioration of the solvent. To solve this problem, sulphur oxides must be pre-processed and removed on the downstream side of the CO2 recovery system beforehand.

Coal is one of the most abundant fossil fuels and thus has a long history of use, from heating to steel production to power generation. Though coal use is both reliable and inexpensive, it is also a major producer of carbon dioxide (CO2) emissions. Research into carbon capture and storage technologies, often termed “clean coal,” has soared since the implementation of the Clean Air Act, designed to regulate airborne contaminants.

CRF scientists Chris Shaddix, Ethan Hecht and postdoc Manfred Geier, in collaboration with professors at the National University of Colombia and the University of Sydney, recently announced the results of their experimental and computational work showing how CO2 influences nitrogen oxide (NOx) formation, coal particle stream ignition, and char particle combustion in unexpected ways during the combustion process.

Over the past two years, improvements in the efficiency of traditional coal power plants have been made through the development of strong, nickel-based superalloys used for steam pipes in the combustion furnace. The development of these advanced steel alloys has allowed the steam turbine to operate at higher input temperatures and pressures, in which the steam is in a supercritical state.

Thus, new “ultra-supercritical” coal power plants have recently been built throughout the world; these plants have thermal efficiencies of 44%, compared to the 32% average efficiency of U.S. coal power plants (which were built 35 years ago). This level of efficiency gain corresponds to a 27% reduction in CO2 emissions (and, indeed, of all pollutant emissions) from the coal power plant.

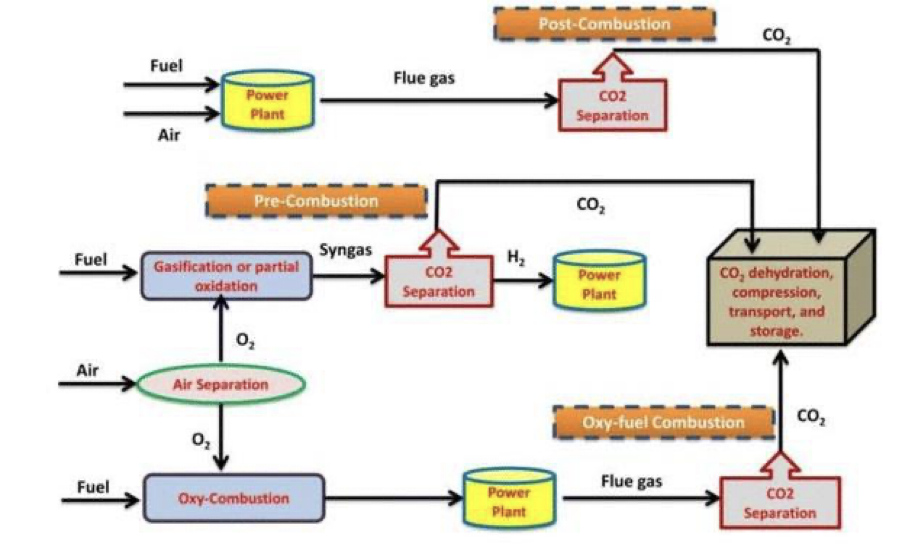

In the US, the conversion approaches constitute two of the three basic routes for fossil fuel carbon capture, namely the ‘oxy-combustion’ and ‘pre-combustion’ routes shown in Figure 3. Recent cost estimates suggest that implementation of any of these approaches to carbon capture would add 40-50% to the cost of electricity relative to a new supercritical coal boiler without carbon capture, and would reduce the plant-wide thermal efficiency back down to nearly 32%.

While CCS technology can significantly mitigate anthropogenic GHG emissions, CCS installations are expected to impose new water stresses due to additional water requirements for chemical and physical processes to capture and separate CO2. In addition to these processes, the parasitic loads imposed by carbon capture on power plants will reduce their efficiency and thus require more water for cooling the plant. Groundwater contamination due to CO2 leakage during geologic sequestration is an additional concern when adapting CCS into power plants.

A review of recent studies highlights three main challenges that would impact water sustainability due to CCS installation:

- Water requirements needed for different stages of CCS

- Changes in groundwater quality due to carbon leakage into geologic formations

- Opportunities for using desalinated brine from saline sequestration aquifers to provide new freshwater sources and offset the CCS-induced water stress

CCS technology is a viable mitigation option for reducing GHG emissions in fossil-fuel power plants. There are three main components of the CCS process: capturing CO2 arising from the combustion of fossil fuels, transporting CO2 to the storage site, and storing CO2 for a long time, rather than being emitted to the atmosphere.

The three common technologies for CO2 capture in CCS systems are the following: post-combustion capture, pre-combustion capture, and oxy-fuel capture. In post-combustion capture, CO2 is separated from the flue gases before they are discharged into the atmosphere. The most commercially common method, amine scrubbing is based on using amine gas treatment to remove CO2 by aqueous solutions of amines.

The CO2 removed from the amine solvent is then dried and compressed to reduce its volume before being transported to a safe storage site. The pre-combustion capture of CO2 is based on the ability to gasify all types of fossil fuels with oxygen or air and/or steam to produce a synthesis gas (syngas) or fuel gas composed of carbon monoxide and hydrogen. Additional water (steam) is then added and the mixture is passed through a series of catalyst beds for the water–gas shift reaction to approach equilibrium, after which CO2 can be separated to leave a hydrogen-rich fuel gas.

This hydrogen can be sent to a turbine to produce electricity or used in hydrogen fuel cells of vehicles. Although the energy requirements in pre-combustion capture systems may be of the order of half that required in post-combustion capture, the precombustion process requires more water for the water–gas shift reaction. In oxy-fuel capture, pure oxygen is used for combustion instead of air and gives a flue gas mixture of mainly CO2 and condensable water vapour, which can be separated and cleaned relatively easily during the compression process.

Conclusion

Transitioning to a low-carbon economy is a reality globally and is necessary to mitigate the risks that are arising from Climate Change. India also has set aggressive targets to reduce the GHG emissions by 2030, we all need to plan for this transitional journey. This is visible in all walks of life, whether it is renewable power of electric vehicles or alternative fuels, or consumers’ preference for low GHG emission products.

Author

Mukul Agrawal

Deepak Fertilisers and Petrochemicals Corporation Ltd.

President – Operations