Without system resistance and ducting, centrifugal fans were built and tested in a shop. However, the fan ought to function with system resistance after it is set up on the field. Here, we developed various scenarios that could influence the fan performance.

- Improper suction ducting

- Immediate bent in the discharge duct

- Undersized ducting

- Dampers close to fan discharge point

- Too many bends close to each other.

- Smaller suction box

- Improper filling of impeller

Here is the case we came across with the defect in the discharge duct, after taking corrective measures in the ducting, fan performance improved.

This boiler, an AFBC, has two 100% capacity FD fans installed, and both fans are running to meet the bed fluidization requirement. Based on the fan design capacity, 1X100% ought to meet the specifications. The boiler has been running with two fans ever since it was commissioned. The plant team claims that the bed will not be adequately fluidized with a single fan operating.

After reviewing the ducting system, we found that there were numerous short radius bends, undersized dampers, and a large pressure drop in the ducting. Each fan discharge duct for the 2×100% fan configuration must be able to handle 100% air volume. Here, we found that the discharge duct cannot accommodate 100% of the air volume.

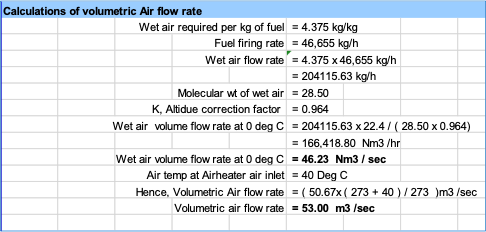

The air volume required for 100% boiler loading was calculated and the design capacity of the fan was higher than the air required, so it was ruled out.

Undersized dampers were located in the undersized ducts, which caused higher turbulence and higher pressure drop. We studied the system and revised ducting system drawings were recommended.

| FD fan load comparison | ||||||||

| Before shutdown | After shutdown | |||||||

| Date | FD fan 3A Per day consumption (MW) | FD fan 3B Per day consumption (MW) | Total power consumed by both FD fan (MW) | Date | FD fan 3A Per day consumption (MW) | FD fan 3B Per day consumption (MW) | Total power consumed by both FD fan (MW) | |

| 07.09.2023 | 9.915 | 10.226 | 20.141 | 02.11.2023 | 10.54 | 0 | 10.54 | |

| 08.09.2023 | 10.066 | 10.085 | 20.151 | 03.11.2023 | 15.553 | 0 | 15.553 | |

| 09.09.2023 | 9.726 | 10.031 | 19.757 | 04.11.2023 | 14.814 | 0 | 14.814 | |

| 10.09.2023 | 9.351 | 9.983 | 19.334 | 05.11.2023 | 15.692 | 0 | 15.692 | |

| 11.09.2023 | 10.205 | 10.068 | 20.273 | 06.11.2023 | 15.694 | 0 | 15.694 | |

| 12.09.2023 | 10.254 | 9.934 | 20.188 | 07.11.2023 | 15.803 | 0 | 15.803 | |

| 13.09.2023 | 10.061 | 9.927 | 19.988 | 08.11.2023 | 15.938 | 0 | 15.938 | |

| 14.09.2023 | 9.918 | 9.958 | 19.876 | 09.11.2023 | 15.574 | 0 | 15.574 | |

| 15.09.2023 | 10.069 | 10.074 | 20.143 | 10.11.2023 | 15.614 | 0 | 15.614 | |

| 16.09.2023 | 10.078 | 10.136 | 20.214 | 11.11.2023 | 15.97 | 0 | 15.97 | |

| 17.09.2023 | 10.137 | 10.058 | 20.195 | 12.11.2023 | 15.748 | 0 | 15.748 | |

| 18.09.2023 | 10.187 | 10.051 | 20.238 | 13.11.2023 | 15.86 | 0 | 15.86 | |

| 19.09.2023 | 8.493 | 11.721 | 20.214 | 14.11.2023 | 15.311 | 0 | 15.311 | |

| 20.09.2023 | 8.147 | 12.599 | 20.746 | 15.11.2023 | 15.44 | 0 | 15.44 | |

| 21.09.2023 | 8.122 | 12.026 | 20.148 | 16.11.2023 | 14.816 | 0 | 14.816 | |

| 22.09.2023 | 8.109 | 12.34 | 20.449 | 17.11.2023 | 15.378 | 0 | 15.378 | |

| 23.09.2023 | 7.894 | 12.248 | 20.142 | 18.11.2023 | 15.408 | 0 | 15.408 | |

| 24.09.2023 | 8.094 | 12.404 | 20.498 | 19.11.2023 | 15.498 | 0 | 15.498 | |

| 25.09.2023 | 8.007 | 12.438 | 20.445 | 20.11.2023 | 15.093 | 0 | 15.093 | |

| 26.09.2023 | 7.922 | 12.498 | 20.42 | 21.11.2023 | 15.285 | 0 | 15.285 | |

| 27.09.2023 | 7.998 | 12.583 | 20.581 | 22.11.2023 | 15.338 | 0 | 15.338 | |

| 28.09.2023 | 8.021 | 12.667 | 20.688 | 23.11.2023 | 15.19 | 0 | 15.19 | |

| 29.09.2023 | 7.775 | 12.202 | 19.977 | 24.11.2023 | 15.592 | 0 | 15.592 | |

| 30.09.2023 | 7.996 | 12.665 | 20.661 | 25.11.2023 | 15.276 | 0 | 15.276 | |

| Average Power Consumption | 20.23 | Average Power Consumption | 15.27 | |||||

| Total Saving / Day | 4.96 | MW | ||||||

Total Power saving achieved 4960 KW/ day.

| There is a spiritual aspect to our lives — when we give, we receive — when a business does something good for somebody, that somebody feels good about themCALL US, WE WILL IMPROVE YOUR SYSTEM |

Author

R.Nagarajaprasath

Boilertech Energy Services