The dramatic increase in operational and fuel costs is undoubtedly the most common day-to-day challenge all sectors face. Due to global environmental pressure, reducing carbon emissions has also become a business imperative.

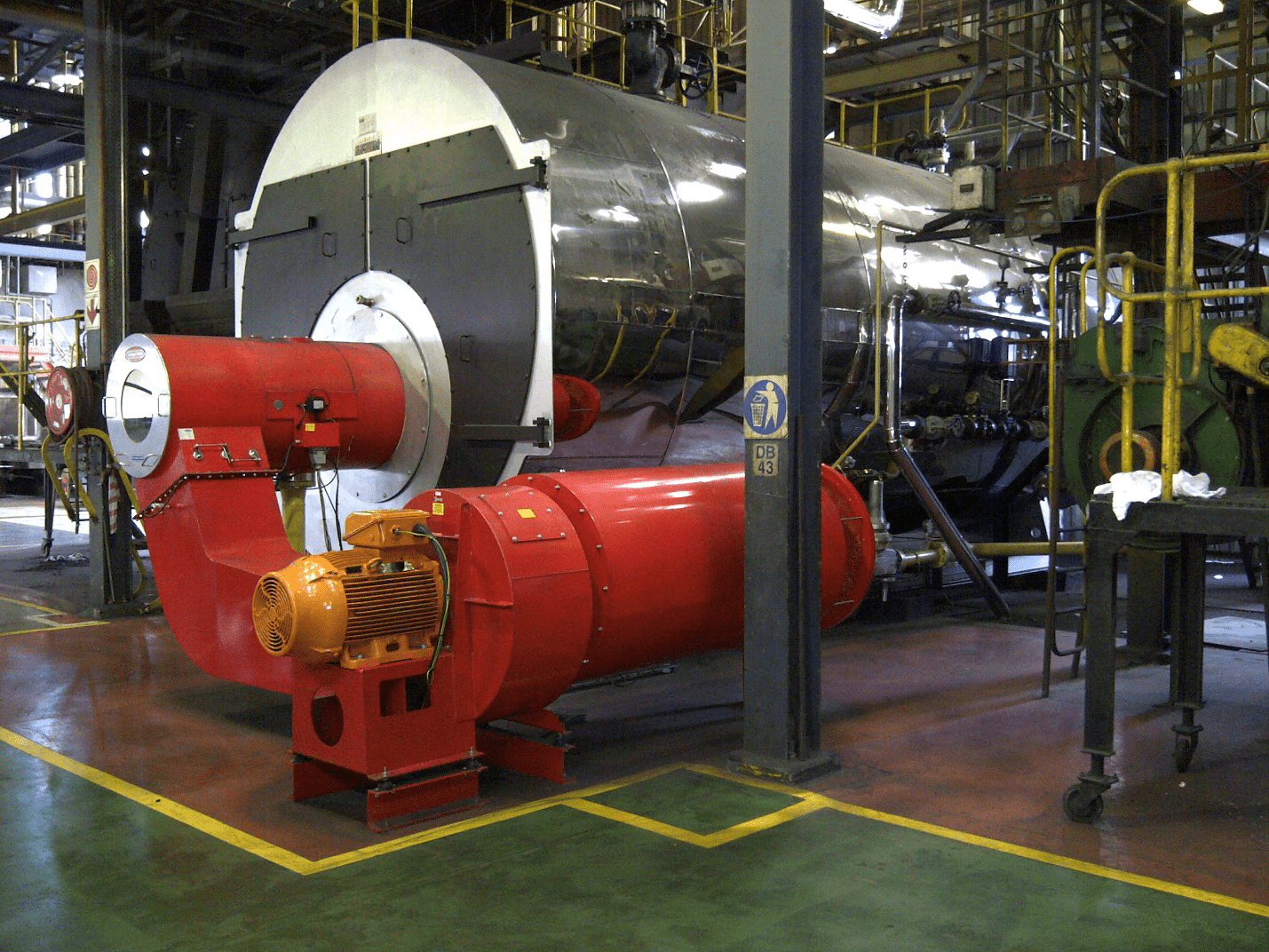

With over 35 years of experience in the boiler and burner industry, Grant Renecle, MD at Combustion Technology, and his team have been addressing these issues as a priority.

Together with their suppliers, Combustion Technology collectively tackles the most cutting-edge and impactful projects utilizing the most innovative products to address such everyday challenges.

“It is essential that we offer our customers innovative technology and customized/turnkey solutions as it plays a huge role in reducing those operational costs”, says Grant. “Energy efficiency is the distinguishing factor at all boiler plants. Our boiler management service and plant optimization delivers up to 15% reduction in fuel consumption.”

“Our solutions are well-known in the industry and guarantee – fuel saving, operational cost saving, optimization of boiler plants and reduced emissions,” says Grant Renecle, Managing Director at Combustion Technology.

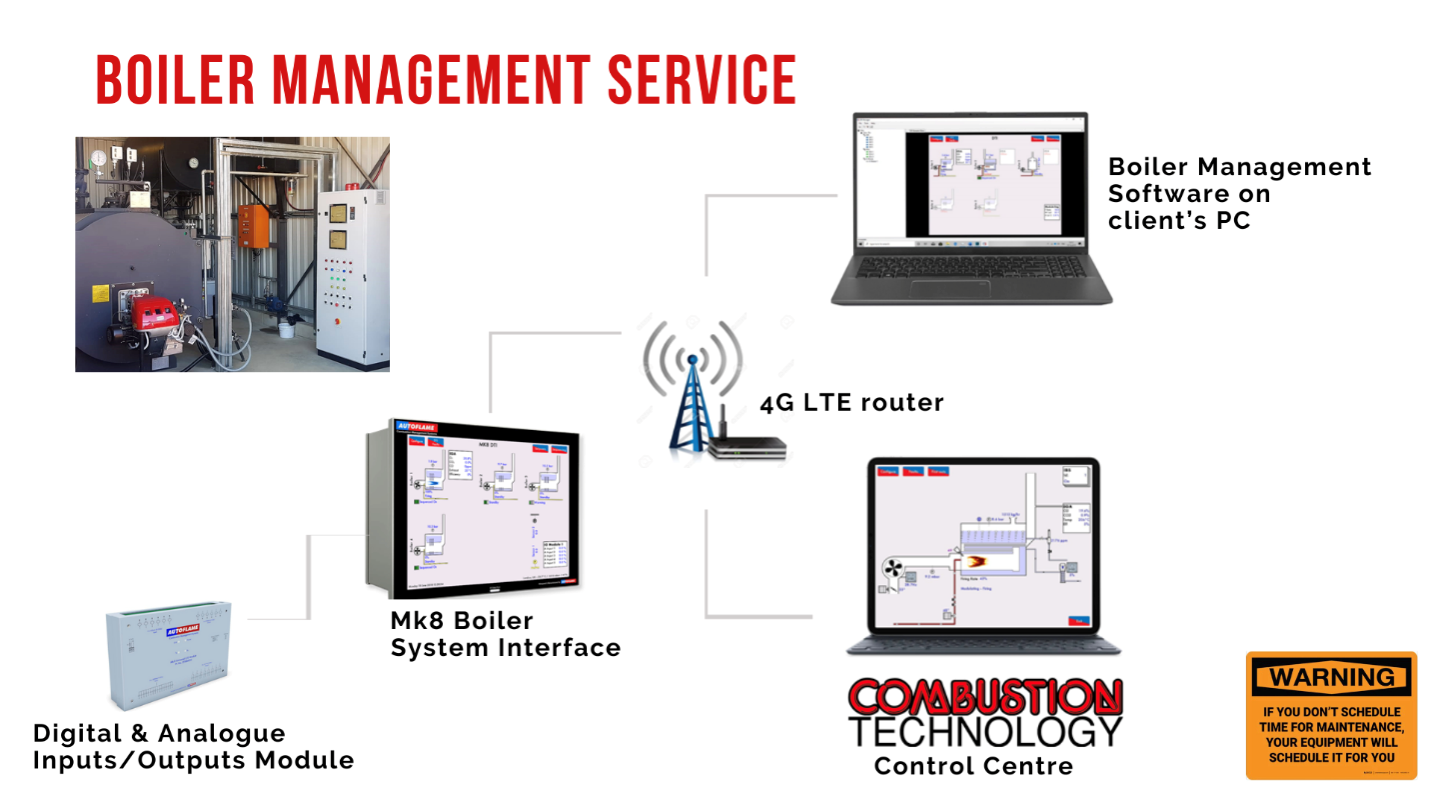

How does our boiler management system work?

Similar to a car’s onboard computer diagnostics, a boiler management system analyses all the boiler plant’s functions, alerting the ‘driver’ when there is a malfunction or actual values are outside normal operating parameters.

Our Engineers analyze this data and submit corrective action coupled with pre-emptive maintenance planning and preventative maintenance. Boiler management services are critical in today’s environment, providing round-the-clock monitoring of your boiler plant.

Remote management: To Maximise boiler plant efficiency, Combustion Technology’s Boiler Management System Interface enables 24/7 off-site monitoring of the plant performance and all the boiler’s essential functions – and as standard fitment, is included with all their boiler supplies.

From the comfort of the office or home kilometres away, customers are able to track and monitor what is happening on-site in real-time to ensure reliability and efficient performance: Such as:

- Steam flow metering

- Water level control

- Fuel consumption compared to steam generation

- Fuel pressure

- Stack temperature

- Ideal emissions (O2, CO2, CO)

- Tracking and monitoring of any element of importance

Built-in alarms alert the engineers at the Combustion Technology head office if set points drift off commissioned values. Immediate interventions are actioned to ensure that it continues to operate optimally.

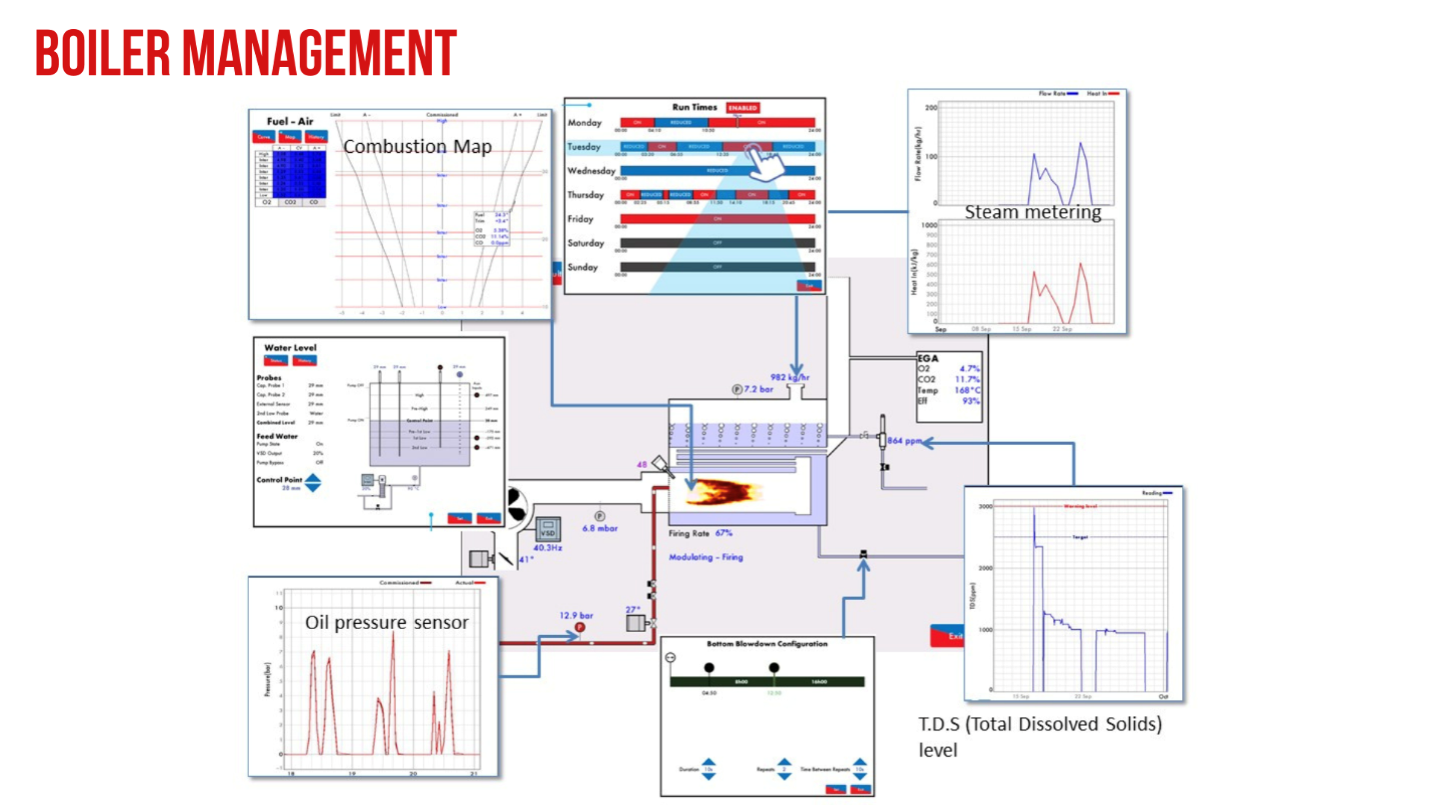

Fuel efficiency: With this service, the company offers further fuel bill savings thanks to the ability to read O2, CO and CO2 emissions and to continuously trim the air/fuel.

This enables users to know immediately when fuel is being wasted and also to track where and when any problems arise. Monitoring the changing ambient conditions, varying combustion values and the conditioning of fuel are all critical factors in an efficient operation.

“It is our commitment to deliver solutions that are real. Energy efficiency cannot just happen on paper; it has to translate into the balance sheet of the business and we guarantee to do exactly that.”

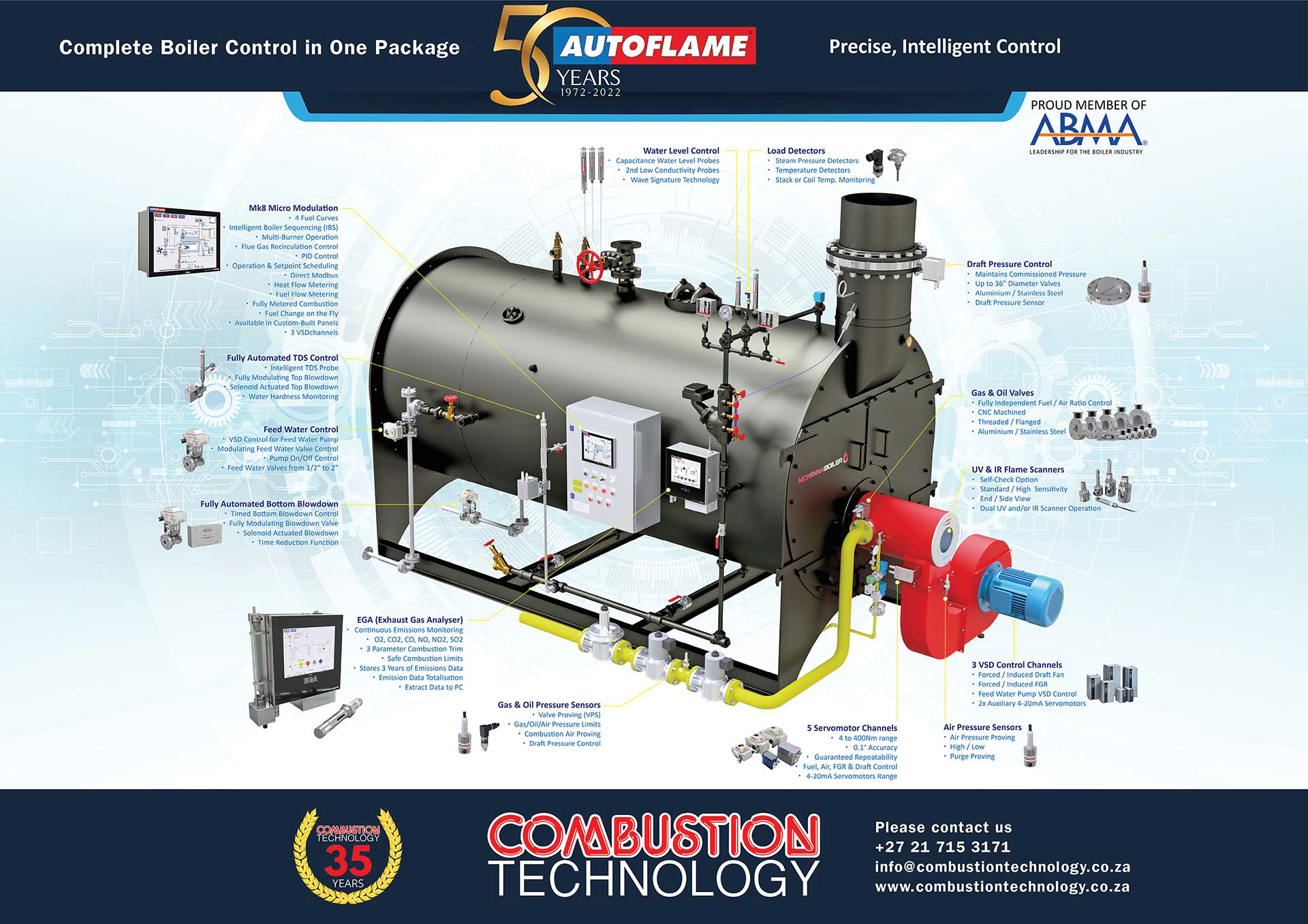

Its Autoflame Mk8 and Mini Mk8 controllers can manage all boiler functions of up to 10 boilers simultaneously.

“Our solution ensures that the boiler works at continuous levels of efficiency, throughout the boiler and burner’s firing range. We offer the products and services and guarantee to achieve exactly that and it’s what differentiates us and saves our clients’ money.”

In testimonials, customers say that their business “has benefited from the monthly boiler management service reporting with key findings. Features that stand out are water temperature alerts, burner service reminders, monitoring and reporting of all key sensor values (stack temperatures) and if cleaning is required”.

The company is regarded as an excellent partner and customers testify to them helping to reduce their annual fuel consumption.

Customers say that they find the boiler functionality and planned maintenance reporting in terms of boiler and burner performance very useful and that their service engineers who have excellent product and technical knowledge, are very quick to respond to site deviations.

“We have proven cost savings and efficiency time and again.” says Grant, “One of our customers recently reported a phenomenal 30 – 40% of fuel saved in one month!”

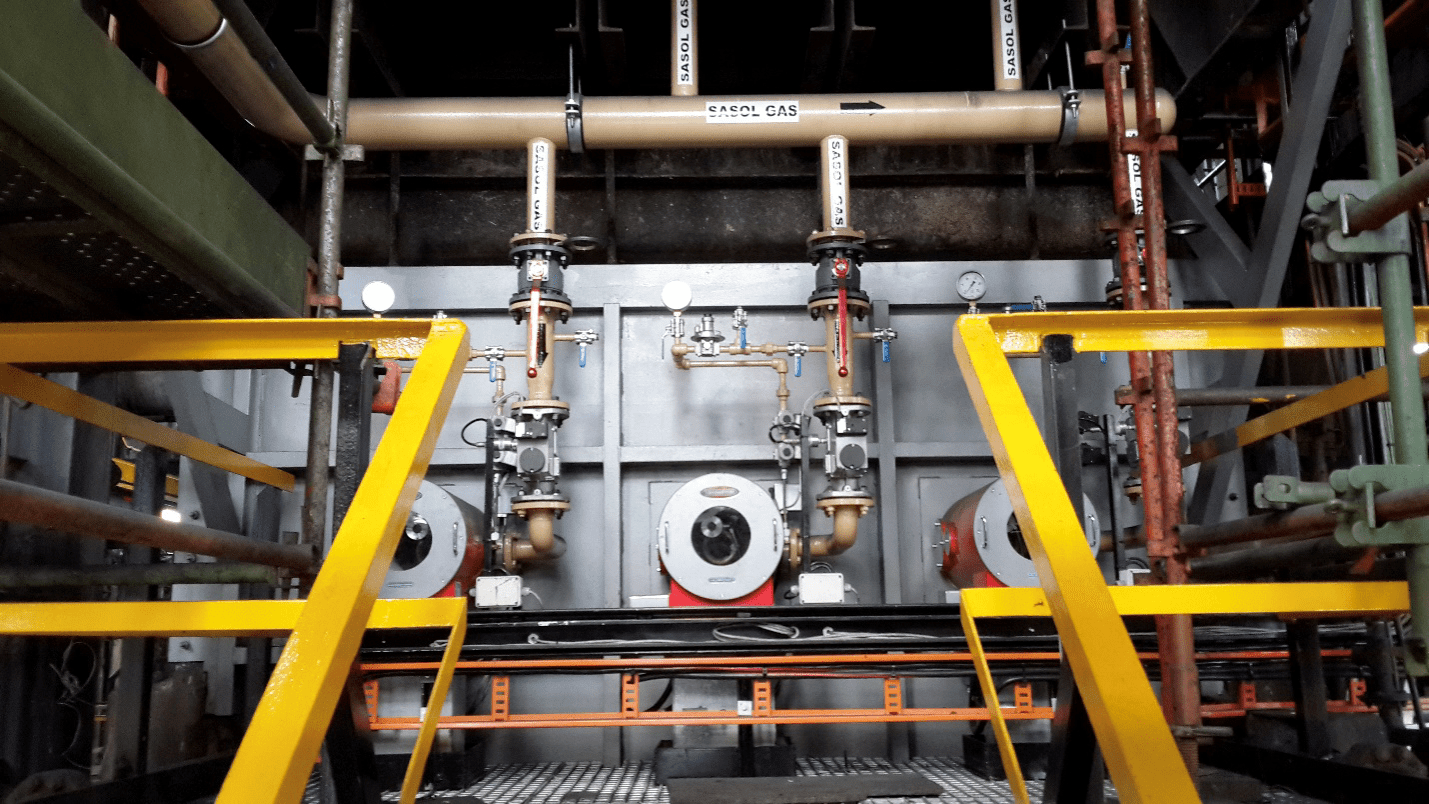

Combustion Technology’s innovative products and a broad range of services guarantee to streamline any boiler plant (business) and make it more cost-efficient. Some of the specialized products and services they offer:

- Boiler and burner sales and installations

- Complete boiler house commissioning

- 24/7 oiler management service

- Energy/emission audits

- Fuel efficiency audits

- Coal-to-gas conversions

- Boiler rentals

- Project management and system design

- Boiler and burner maintenance and service

- Statutory boiler and burner inspections

- Preventative maintenance and service level agreements

- Training

- Spare parts

Enquiries: +27 21 715 3171 | [email protected]

Flagship sites:

Testimonials from existing customers:

“The overall insights provided in the Boiler Management Report regarding Boiler Functionality and Planned Maintenance are very useful” Ernst Nortje – Upward Spiral, Johannesburg, SA

“The response rate to logged calls and support turnaround times of the Service Engineers are excellent. They display excellent product and technical knowledge” Johan Hatting – Clover, Cape Town, SA

“Combustion Technology is an excellent partner and has helped us reduce our annual fuel consumption on our HFO fuelled Boiler. Their service levels are top quality and I highly recommend them.” Lawrence Lombard – MPACT Ltd, Kuilsrivier, SA

“Our business has benefited from the monthly Boiler Management Service Reporting with key findings. Features that stand out are water temperature alerts, burner service reminders, monitoring and reporting of all key sensor values i.e. stack temperatures and if cleaning is required.” Antoine van Heerden – ButtaNutt, Paarl SA

“Combustion Technology’s 24/7 Boiler Management System excellent; they are very quick to respond to site deviations” Brian Richter – Johnson & Johnson, East London, SA

“I find the Boiler Functionality and Planned Maintenance reporting in terms of boiler and burner performance very useful” Brian Taylor – Desert Diamond Fishing, Cape Town, SA