Introduction:

In the world of industrial operations, efficient maintenance, cleanliness plays a crucial role in ensuring equipment longevity and operational effectiveness. we’ll explore the fascinating technology of sonic soot blowers and how they are revolutionizing the way industries clean their equipment, especially in power plants and other facilities where soot and ash build-up can be a significant issue.

What is a Sonic Soot Blower?

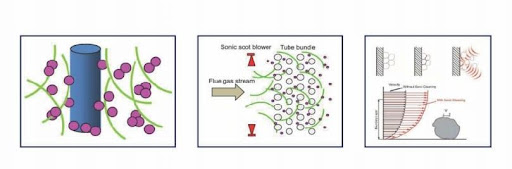

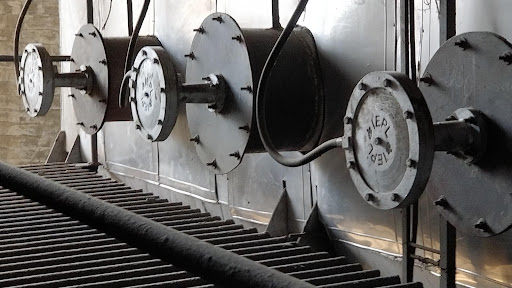

A sonic soot blower is a high-frequency sound wave-based cleaning system designed to remove soot, ash, and other debris from various surfaces, including heat exchanger tubes, boilers, and more. Unlike traditional methods that rely on physical force, such as steam or air, sonic soot blowers use the power of sound waves to dislodge and remove deposits.

Our Commitment to Sonic Soot Blowers:

We understand the critical role that efficient maintenance and cleanliness play in industrial operations, especially in sectors where soot and ash build-up can significantly impact performance. As a leader in the industry, we have made it our mission to harness the power of cutting-edge technologies like sonic soot blowers to revolutionize the way industries clean their equipment.

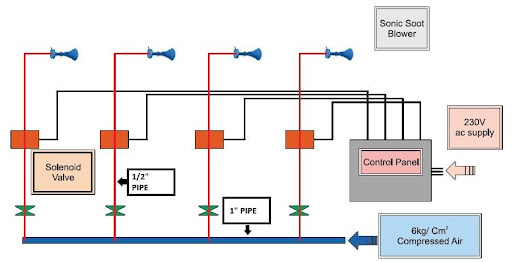

How Sonic Soot Blowers work:

- Sound waves: Sonic soot blowers generate high-frequency sound waves, typically in the ultrasonic range. These waves propagate through the targeted equipment’s tubes or surfaces.

- Energy transfer: The sound waves transmit their energy to the soot and ash deposits, causing them to vibrate and loosen from the surfaces.

- Debris removal: As the deposits become dislodged, they are blown away by the gas flow or another fluid medium, leaving the equipment clean and free from obstructions.

Benefits of Sonic Soot Blower in boilers:

- Facilitate energy management: Reduce unscheduled breakdown, and boiler damages, and increase overall plant safety, availability, reliability, and production stability.

- Improves operational economy: Better boiler efficiency, less capacity reduction, and sustains superheated steam temperature to improve turbine performance.

- Reduce consumption of: Steam, ID fan power, and lower system maintenance needs.

- Reduce air pollution: Through successive short-cycle cleaning to level out soot discharge peaks.

Advantages of Sonic Soot blowers:

- Efficiency: Sonic soot blowers can effectively remove deposits that might be difficult to reach with conventional methods, making them highly efficient.

- Energy savings: By preventing the build-up of soot and ash, industries can maintain optimal thermal efficiency, reducing fuel consumption and operating costs.

- Environmental benefits: Cleaner equipment produces fewer emissions, contributing to a cleaner and greener environment.

- Extended equipment life: Regular use of sonic soot blowers helps extend the life of industrial equipment by preventing corrosion and reducing wear and tear.

- Reduced downtime: Cleaning with sonic soot blowers can be performed while the equipment is still in operation, reducing downtime and increasing productivity.

Applications of Sonic Soot blowers:

- Power plants: Sonic soot blowers are widely used in power plants to keep boilers, economizers, and air preheaters clean, ensuring efficient energy production.

- Industrial furnaces: In facilities with high-temperature processes, such as steel mills and cement kilns, sonic soot blowers help maintain equipment performance.

- Chemical plants: Equipment like heat exchangers in chemical plants benefit from the regular use of sonic soot blowers.

- Waste-to-energy facilities: These facilities utilize sonic soot blowers to keep combustion chambers and heat recovery systems free from deposits.

Conclusion:

Sonic soot blowers have become a game-changer in industrial cleaning, helping industries across the board maintain their equipment’s efficiency and reliability. With their ability to efficiently remove soot and ash deposits through the power of sound waves, they offer numerous advantages, including energy savings, environmental benefits, and extended equipment life.

As technology continues to advance, we can expect sonic soot blowers to play an even more prominent role in industrial maintenance, contributing to cleaner and more sustainable operations.

If you’re involved in industrial operations, it’s worth considering the adoption of this innovative cleaning technology to ensure your equipment operates at its best while reducing environmental impact.

Author

PIYUSH KAKADIYA

Certified Energy Auditor by BEE

Director: INNOVATIVE ENERPRO PVT LTD

Email: [email protected]