Name: Mehran Izadkhah

Designation: Global Riskwise Engineering Product Manager, Asset Integrity Management

Organisation: TWI, Malaysia

Education: Bachelor of Science (Honours), Chemical Engineering, University of Tehran, Iran

Mehran started his career with the Iranian Offshore Oil Company in 2006 with some prior field experience and worked for around two years on offshore platforms as a Site Engineer. He then joined TWI Central Asia in January 2009. His site experience and the support from TWI led him to gain more responsibilities in asset integrity engineering of oil and gas production facilities. Since then, he has been responsible for risk-based inspection, damage mechanism identification, fitness-for-services in accordance with API 579, repair and maintenance relating to production equipment and offshore structural integrity assessment, as well as pipeline external/internal corrosion direct assessments, over 3000 km pipeline integrity assessment, materials selection, corrosion control, cathodic protection, protective coatings, and failure investigations.

Mehran was involved in developing procedures, methodologies, and software algorithms for a fully quantitative probability of failure and semi-quantitative consequence of failure for Onshore/Offshore Gas/Liquid pipelines following the requirements of relevant pipeline standards. Mehran and his colleagues published an article in “World Pipeline Magazine” in October 2018 named “A Game of Risk and Consequence” regarding the Risk assessment approach for onshore pipeline systems.

He also wrote an article with ADMA OPCO to develop a probabilistic study on the dead legs in ADMA’s process plants and offshore facilities subjected to internal thinning, presented at ADIPEC Exhibition in 2017.

With over fourteen (14) years of experience, he is now the Global RiskWISE Software Product Manager. Mehran leads and manages developments of TWI’s RBI and Integrity management software, supporting customers to maintain the integrity of their assets.

Introduction to Risk Based Inspection (RBI)

The inspection approaches for power plants, boilers, heat recovery systems, structures, and machinery are usually determined by custom industry practices based on prescriptive codes and health and safety legislation. The inspection frequency, methods employed, and locations examined were determined by the type of equipment with little consideration given to its age, specific duty, or likely damage. Ever-growing operational experience and a better appreciation of plant aging and associated hazards have led the industry to adopt a risk-informed approach to inspection planning. These modern-day approaches require specifying an inspection appropriate to manage the risk of failure within regulatory expectations.

The risk-based inspection involves developing a scheme of inspection based on knowledge of the risk of failure. The critical element in the process is to perform risk analysis for the asset. Risk analysis includes the assessment of the likelihood (probability) of failure due to flaws, damage, deterioration, or degradation and an assessment of the consequences of such failure.

The information gained from this process is then used to identify:

- the type of damage that may potentially be present

- where such damage could occur

- the rate at which such damage might evolve

- where failure may lead to catastrophe.

Areas at high risk usually have credible damage mechanisms combined with high consequences from structural failure, the release of hazardous substances, or stored energy. A suitable inspection scheme will deploy techniques at a frequency that provides adequate confidence about the condition, taking the damage mechanisms and the reliability of the inspection techniques into consideration.

Risk-based inspection can generally be utilized in any industry sector. However, there has been most interest from the power and petrochemical sectors. Some of the examples reflecting the need, approach, and benefits of RBI implantation may include:

A report on best practices for risk-based inspection as a part of plant integrity management. [www.hse.gov.uk/research/crr_pdf/2001/crr01363.pdf] published by the UK Health and Safety Executive in 2006.

The RIMAP project to develop risk-based inspection and maintenance procedures for European Industry was launched by the European Commission in 2000. [ Jovanovic A, Overview of the RIMAP project and its deliverables in the area of power plants, IntJPVP, vol 81, issues 10 and 11, pp815-824, 2004]

The American Petroleum Institute (API) has published recommended practices and a base resource document for risk-based inspection relevant to refineries [API Recommended Practice 580 and Base Resource Document 581].

Industry sees RBI as a way to obtain economic benefits from extended run lengths and as means of using inspection resources effectively through the use of suitable automated NDT techniques and/or thoughtfully developed non-invasive inspection schemes. Regulatory pressure will ensure that the process of RBI is carried out rigorously so that inspection decisions are based on adequate information and expertise. However, in some industry sectors (e.g., nuclear) with very high consequences of failure, an approach to assure safety based only on RBI may not be entirely tenable.

In addition, RBI is a risk assessment and management tool that focuses on risk management topics that are not entirely addressed in other organizational risk management efforts, such as process hazards analyses, IOWs, or reliability-centered maintenance. Integration of these risk management efforts, including RBI, is the key to a successful risk management program.

RBI produces equipment inspection and maintenance plans that identify the actions that should be taken to provide reliable and safe operations. An RBI effort can give input for an organization’s annual planning and budgeting to define the staffing and funds required to maintain equipment operation at acceptable performance and risk levels [API Recommended Practice 580 and Base Resource Document 581].

Implementation Approach

The Risk Based Inspection (RBI) can be applied qualitatively, quantitatively, or using an aspect of both, i.e. semi-quantitative. Each approach provides a systematic way to screen for risk, identify areas of potential concern and develop a prioritized list for more in-depth inspection or analysis. Each approach covers calculations of the Probability of Failure (POF) and the Consequence of Failure (COF) at the equipment level. The complexity of the risk calculation is a function of the number of factors that can affect the risk. In general, RBI focuses on a systematic determination of relative risks.

TWI is one of the world’s leading organizations for RBI implementation. It regularly contributes to standard committees towards developing various RBI methodologies for various equipment and structures such as Pipelines, Jacket legs, Well conductors, etc. TWI supports its clients in developing and implementing Asset Integrity Management plans, including RBI, Inspection, high-level Fitness for Service, Root Cause Analysis, and life extension approaches.

TWI provides RBI software as well as implementation for different types of equipment. Our main core RBI software – RiskWISE® – since its start of development in the late 1990s remains as RBI and Risk-Based Management (RBM) engineering software designed in accordance with industry-accepted and proven concepts of RBI and RBM. It covers the concepts detailed in API Recommended Practice (RP) 580 – Risk Based Inspection (RBI) and API RP 581 – Risk Based Inspection Technology. The user-friendly software has been designed by plant personnel to help improve your safety and facilitate increased run times while reducing expensive outage costs.

RiskWISE® automates the fully quantitative methods and procedures of risk-based inspection (RBI) in process plants, according to API RP 580, API RP 581, and semi-quantitative assessment as per industry best practice. It is used to enable the facility operators or owners to establish an optimum inspection strategy and inspection programs and make maintenance decisions. Software development incorporates years of experience and expertise in the inspection. It aligns with the requirements of relevant standards, including API 581, API RP 580, and ASME.

Providing a fully quantitative risk-based inspection assessment platform as per API RP 581:2016, RiskWISE uses a regularly updated database to include all relevant damage mechanisms along with guidance to help the integrity engineers formulate the probability and consequences of failure.

Boilers are one of the assets with a variety of failure mechanisms. Understanding these mechanisms will help power plant owners significantly reduce the number of required inspections while managing the risk of the whole plant in a cost-effective approach.

Executing the inspection and detailed assessment of boilers and boiler components gave TWI vast experience and knowledge to develop specific RBI methodologies quantitatively and semi-quantitatively for boilers and their components. This methodology covers all specific damage types in boiler components and heat recovery units, which are not addressed in API 581. Using this methodology, TWI together with its collaboration has developed a software called “POWER-RBI” to assess the risk and help the power plant owners to maintain the plant risk to the desired level. POWER –RBI will help the plant owners to:

- Avoid forced boiler outages and improve planned outage work

- Manage asset-related documents, P&IDs, MRBs, P&ID tagging and results

- Map and predict failures using available standards models

- Manage inspections and automate the flow of information/work

- 2D/3D visualization of the Corrosion Monitoring Locations (CMLs)

- Inspection planning based on Damage mechanisms

- Flexible RBI methodology based on the availability of data

To ensure all boiler threats are addressed in the methodology, all types of damage mechanisms were addressed in both Semi, and fully-quantitative RBI approaches in POWER-RBI. The main damage mechanisms are:

- General thinning

- Localized tube thinning

- Caustic SCC

- Chloride Stress Corrosion Cracking

- External chloride stress corrosion cracking

- Thermal fatigue

- Long-term and Short-term Creep

- Creep-fatigue

- Mechanical fatigue

- Low alloy steel embrittlement

- Softening

- Flow-induced turbulence damage

- Mechanical excitation

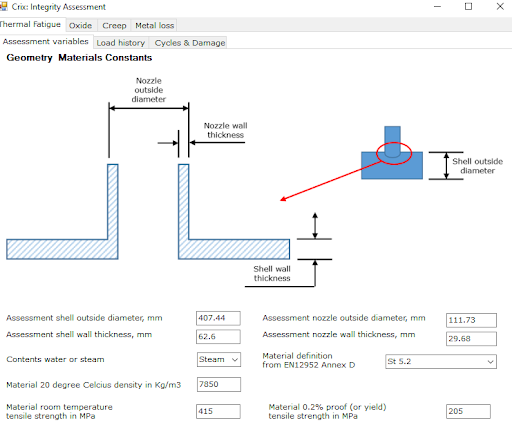

In addition to the RBI approach, a recently developed application called Crix calculates the remaining life of the components for Creep, Thermal Fatigue, oxidation, and metal loss will present.