The spent wash incineration technology has proven to be the best technology in the presence of other technologies for the past years by being clean and zero effluent discharge system. Adding to it, spent wash incineration technology has also been the best revenue generation system. Advantages of spent wash incinerator by FIVES CAIL-KCP:

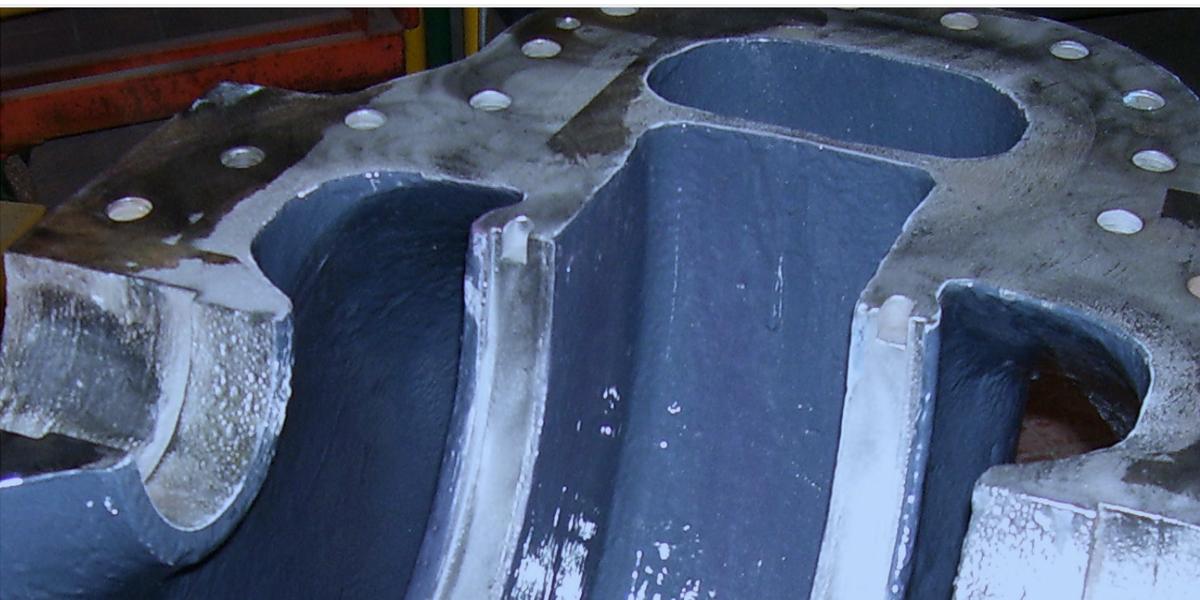

Travelling grate: The most successful firing technology for the spent wash incinerator

Travelling grate experienced as the most suitable technology for the firing of spent wash with biomass fuel, where bottom ash and potash rich fly ash is made available separately so that potash rich fly ash can be sold at a better commercial price.

Travelling grate as a multi-fuel firing boiler is an ideal solution for the high fibre content fuel like bagasse and also suitable for high calorific value fuel like coal.

In case of a shortage of spent wash, the boiler is capable of generating 100% Maximum Continuous Rating, MCR while firing only with bagasse or coal.

Brix value fluctuation is quite a common issue in distillery operations. For the same, it is observed that the spent wash with 42 – 45 degrees Brix is burnt in this boiler without much disturbance in the combustion and Spent wash with 60 Brix performs well in this boiler.

The simple movement of grates and a single hydraulic drive for the entire travelling grate movement makes the travelling grate technology the Least power consumption technology among its competitor.

No need for separate bed material, easy operation and maintenance of the boiler leads to the low maintenance cost when compared to other technologies.

No need for pressurized air fan, a rare possibility for clinker formation, no fuel leakage between the grate bars, etc. are the added advantages to the travelling grate technology spent wash incinerator.

Bagasse: Best suitable supporting fuel to the spent wash incinerator

The government is encouraging renewable energy or green energy as far as possible. The flexibility of using either bagasse, rice husk or any other biomass in place of coal supports this initiative. The use of fossil fuels is not a green initiative. If the use of fossil fuel comes under regulations in future, potential liabilities or taxes will be a regular additional burden at a later stage. It will be a costly solution to go for modification at a later stage.

Bagasse supported boiler will have lesser SOx (traces) in the flue gas.

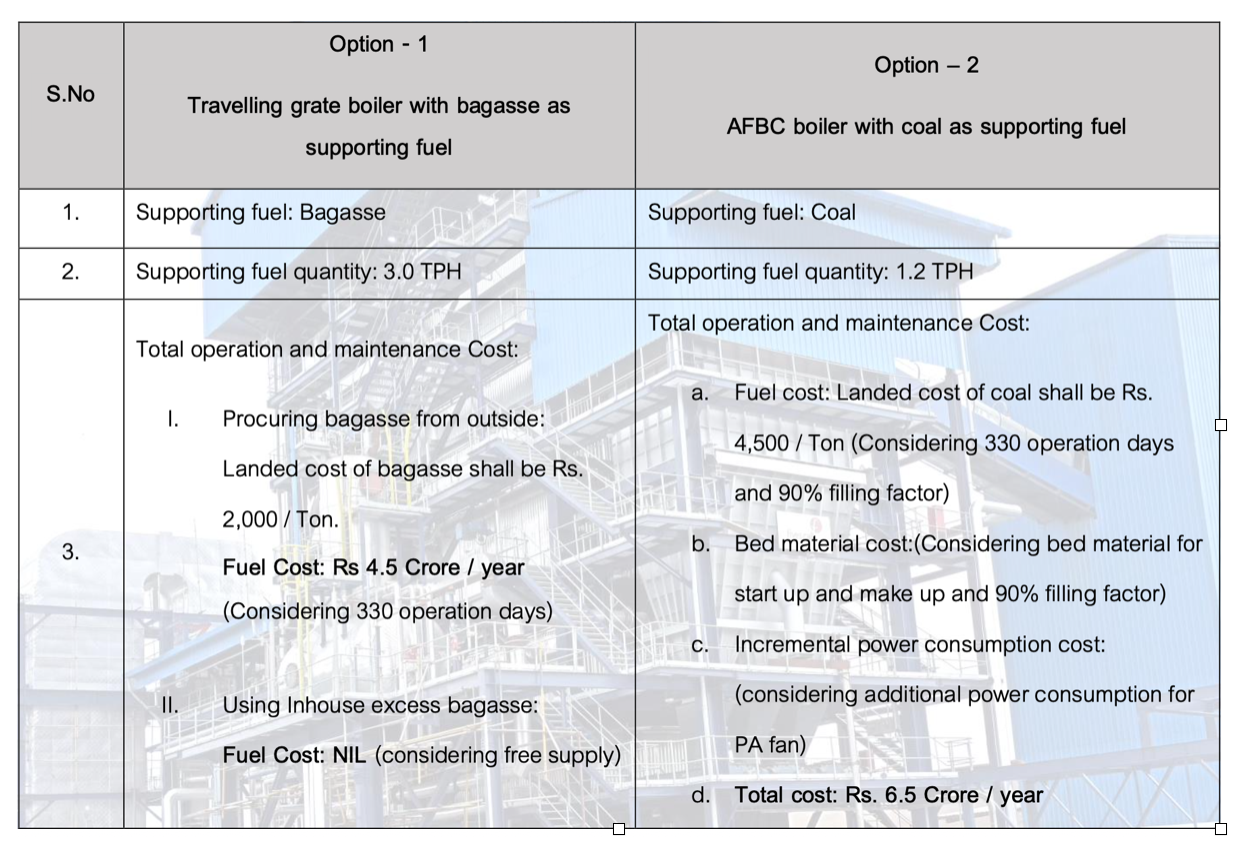

An OPEX comparison between the travelling grate and Atmospheric Fluidised Bed Combustion (AFBC) boiler for a typical 20 TPH spent wash incinerator

There is no major difference in the CAPEX between Travelling Grate Spent wash Incinerator and AFBC spent wash incinerator, only operation cost (OPEX) for both the technology is considered.

Procuring bagasse from outside: additional expenditure of INR 2 Crore (approx.) for every year for AFBC boiler. Using in-house excess bagasse: additional expenditure of Rs 6.5 Crore (approx.) for every year for AFBC boiler.

S. Manivannan-Head Marketing FIVES CAIL-KCP Limited