The term “biomass” refers to materials derived from plant matter such as trees, grasses, and agricultural crops. These materials, grown using energy from sunlight, can be renewable energy sources for fueling many of today’s energy needs. The most common types of biomass that are available at potentially attractive prices for energy use at federal facilities are waste wood and wastepaper.

One of the most attractive and easily implemented biomass energy technologies is co-firing with coal in existing coal-fired boilers. In biomass co-firing, biomass can substitute for up to 20% of the coal used in the boiler. The biomass and coal are combusted simultaneously.

When it is used as a supplemental fuel in an existing coal boiler, biomass can provide the following benefits: lower fuel costs, avoidance of landfills and their associated costs, and reductions in sulfur oxide, nitrogen oxide, and greenhouse gas emissions. Other benefits, such as decreases in flue gas opacity, have also been documented.

Application

Biomass co-firing can be applied only at facilities with existing coal-fired boilers. The best opportunities for economically attractive co-firing are at coal-fired facilities where all or most of the following conditions apply:

(1) coal prices are high;

(2) annual coal usage is significant;

(3) local or facility-generated supplies of biomass are abundant;

(4) local landfill tipping fees are high, which means it is costly to dispose of Biomass.

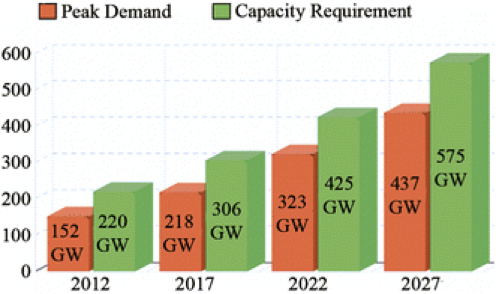

Energy Challenges in India

Sub-critical pulverized coal (PC) technology is used in most of the coal based thermal power plants. Coal is required in large quantities for power generation and India has abundant reserves of this fossil fuel. However, indigenous coal production hasn’t been able to meet the demands and hence significant proportion of coal is imported from overseas.

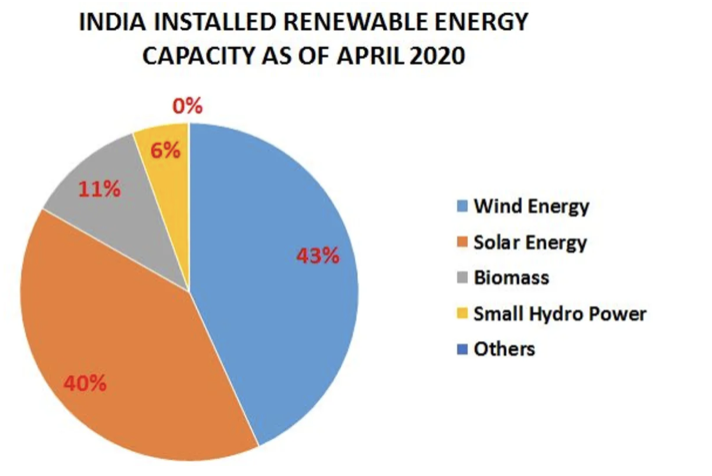

BioEnergy in India – Significance and potential

India is a land of agriculture. It also receives regular sunshine almost throughout the year and hence suitable for the growth of energy crops as well. Consequently, there is an abundant supply of bioenergy that has the potential to complement the fossil fuels, mainly coal, in generating power for the steadily increasing population in India.

As per a recent study sponsored by MNRE, the current availability of biomass in India is estimated at about 750 million metric tonnes per year. The Study indicated estimated surplus biomass availability at about 230 million metric tonnes per annum covering agricultural residues corresponding to a potential of about 28 GW. This apart, about 14 GW additional power could be generated through bagasse-based cogeneration in the country’s 550 Sugar mills, if these sugar mills were to adopt technically and economically optimal levels of cogeneration for extracting power from the bagasse produced by them.

Biomass has the potential to change the rural energy landscape of India in two ways:

• Electrification of nearly 75 million rural households currently un-electrified in India (25,000 MWe)

• Using bioenergy has a multiplier effect on the development of the economy as about 60% of the total plant cost is circulated back into the rural economy and could also offer employment opportunities to the rural community.

Issues in the bioenergy sector in India

- Rising biomass prices

- Lack of up-to-date information on availability of biomass resources.

- Biomass transportation and handling issues

Biomass supply cost

The price for primary biomass is determined by three factors:

1) the supply side factor (technically achievable biomass supply volume with associated cost),

2) the demand side factor (energy demand, land demand associated with food and feed production/energy crop production/and other usages, the price of competing usage (i.e., fossil fuel price, food price)), and

3) the policy factor (i.e., tax incentives, blending mandate).

All three factors are dynamically interlinked and require economic models for detailed assessment. In India, no reliable statistics is available for the price of the residue and waste biomass. The supply cost of each biomass type can be estimated for each region and a bottom-up approach can be applied to estimate the total cost.

Co-firing of coal and biomass – a better way to utilize the biomass resources in India:

Estimations show that significant percentage of coal, up to 30%, could be replaced by biomass; however, there exists optimum levels of biomass that can be co-fired with coal based on technical and economic limitations.

There are three major options generally available for co-firing biomass with coal. Each of them has its own advantages and disadvantages. All the options have been successfully employed either on a demonstration-or commercial-scale. In direct co-firing, both biomass and coal are combusted in the same furnace. Both coal and biomass may use the same fuel handling and feeding systems or different ones depending on the biomass characteristics. Direct co-firing is the cheapest and most commonly used method. Indirect co-firing utilises a gasifier to convert the solid biomass fuel into a gaseous fuel which could be co-combusted with coal in the same furnace. This method, although expensive, could be used for a broader range of biomass fuels; biomass fuels that are difficult to grind could especially be utilised through indirect co-firing.

Challenges in the implementation of co-firing in India

India has an ideal situation where co-firing of coal and biomass should be in optimal use. However, it has not been the case.

The big question that immediately arises is why this technology has been overlooked?

Has it been tried and tested enough to be ignored? A preliminary analysis on this issue points to the following factors:

• Technical problems arising from the combustion of biomass (even if minor) in furnaces designed for coal combustion

• Further capital investment in the power plant to accommodate biomass storage, processing, and feeding

• Fluctuating availability of biomass and unpredictable prices

• Diversity in the biomass available in India

• Utilities ‘concern about issues arising from the use of biomass and their effect on the plant availability and power production

• Utilities’ mindset to only adopt conventional pulverized coal technology that has proven to be successful over the years with indigenous coal and now with imported coal as well

Existing biomass power plants face the challenge of collecting vast amounts of crop residue for sustained power production. Some of the major barriers faced in faster realization of available biomass power potential for a variety of end user applications are,

(i) inadequate information on biomass availability,

(ii) absence of organized formal biomass markets,

(iii)problems associated with management of biomass collection, transportation, processing and storage; problems associated with setting up large size biomass plants,

(iv) non-availability of cost-effective sub megawatt systems for conversion of biomass to energy in a decentralized manner, and

(v) lack of capability to generate bankable projects on account of financial and liquidity problems,

(vi) Policy and regulatory framework, Local, social, and environmental instances of co-firing studies/trials in India

• Laboratory scale studies on combustion of Indian coal and biomass blends have been reported.

• Co-firing trials have also been performed previously in an industrial scale cogeneration unit in India with an aim to optimize the biomass/coal blending ratio from an emissions point of view

• Thermax biomass boilers have been used to fire both biomass (mainly bagasse) and coal mainly in cogeneration plants located in sugar mills.

• Indian coal-based thermal power plants have been co-firing indigenous and imported coal for quite some time now.

• India is currently focusing on reducing the CO2 emissions from its thermal power plants.

Government of India initiatives

The Ministry of New and Renewable Energy (MNRE) in India has taken up programmes on Biofuels through research, development and demonstration projects at various research, scientific and educational institutes, universities, national laboratories, industry, etc. India has adopted agenda and actions based on the UN post-2015 development agenda

Transforming our world: the 2030 Agenda for Sustainable Development, with 17 Sustainable Development Goals (SDGs) for the people, planet and prosperity reflecting the commitment of shifting on to a sustainable and resilient path. The overall aim of the Integrated Bio Energy Mission would be to contribute to achieve the GHG emissions reduction targets as agreed in the Nationally Determined Contributions at COP 21 through the progressive blending/ substitution of fossil fuels such as coal, petrol, diesel, natural gas and LPG with biomass pellets, bioethanol, biodiesel, biomethane, and similar green fuels, both for electrical and non-electrical uses. The indicative outlay for the Mission would be Rs 10,000 Crore from 2017-18 to 2021-22. The major goals of the National Policy on Biofuels are the development and utilization of indigenous non-food feed stocks raised on degraded or waste lands, thrust on research and development on cultivation, processing and production of biofuels and a blending mandate of 20% Ethanol and Bio-diesel by 2017. The objective of biofuel programme is to support R&D, Pilot plant/Demonstration projects leading to commercial development of 2nd Generation biofuels.

(Source: http://mnre.gov.in/filemanager/UserFiles/biofuel_policy.pdf).

The ministry supports R & D projects for development of technologies for production of biofuels through Biogas, Pyrolysis and Gasification, besides promoting deployment of technologies for pilot and full-scale projects on biofuels in general.

Rishikesh Deshpande, Managing Director and Project Consultant, Sustainable Biobrikets Pvt. Ltd

Vinod Kumar Garg

September 15, 2022 at 11:51 pmWant information for use of biomass fuel in Faridabad, delhi NCR