Name: Vivek Shinde

Forbes Marshall

Group Head

The basic theory of combustion

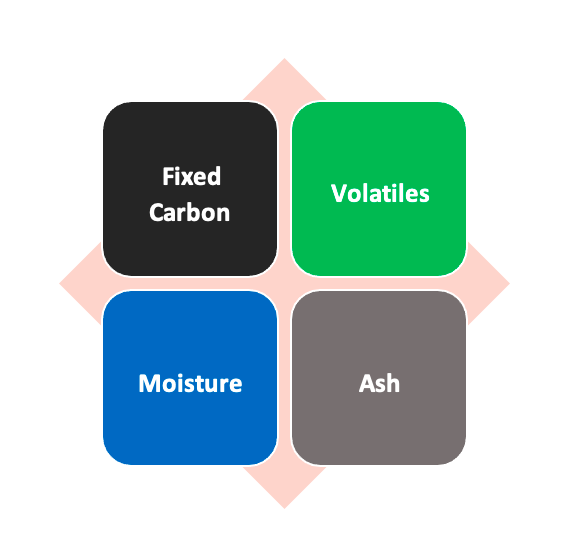

Fuels are composed of the following:

Family of fuels

Biomass Family

Fossil Fuel Family

Combustion Cycle

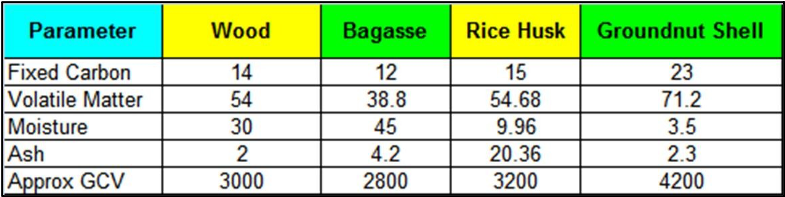

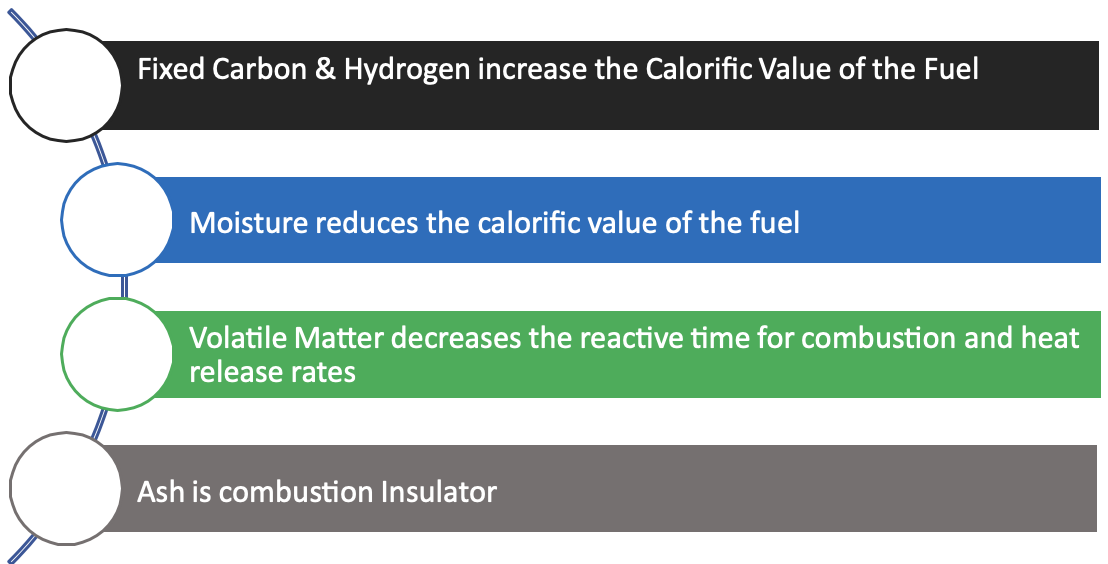

Properties of the Fuel & their Effects

Summary of properties

- Does a high calorific value mean quick combustion and quick heat release rates? No…

- Higher volatiles – quick combustion and quick heat release rates

- Higher volatiles in fuel also has the advantage of the lower unburnt left in ash during the combustion process

- Volatiles constitute the flame and fixed carbon are the glowing embers seen during the combustion process

- Fixed Carbon takes higher temperatures and a longer time to burn

- Size and porosity of the fuel – highly porous fuels have lower energy per unit volume and require larger volume and surface for combustion

- The active surface area of fuel for combustion – the fuel should be sized to provide the most optimum active surface area for combustion. Ideal fuel sizing is 5mm to 20 mm based on the combustion technology used

- Fuels < 5 mm result in very high un-burnt as the fuel becomes very light and the combustion process fails to offer the desired residence time

- Fuel > 20 mm results in incomplete combustion on account of lower active surface area

- The higher the moisture, the higher the heat lost from the combustion process

Types of Combustion

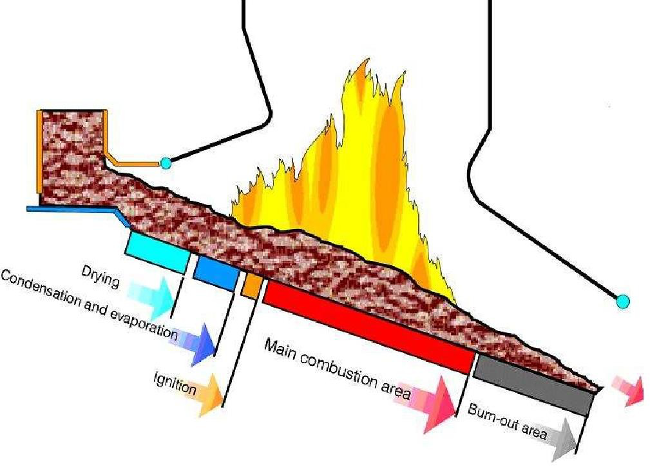

Progressive Combustion

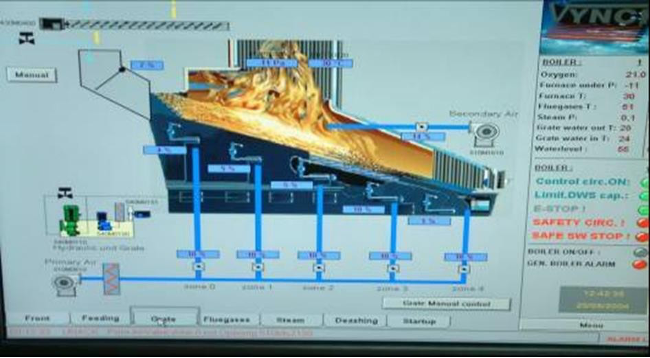

The type of combustion where there is progressive movement of the fuel and the grate and where there is relative movement between the grate and the fuel move during the process of combustion.

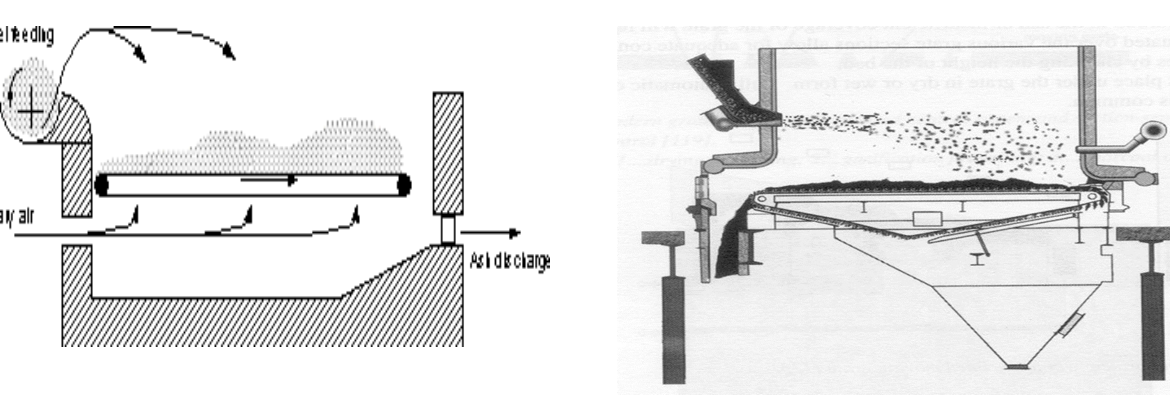

Semi-Progressive Combustion

The type of combustion where there is progressive movement of the grate but there is no movement of the fuel on the grate i.e., no relative movement between the grate and the fuel move during the process of combustion.

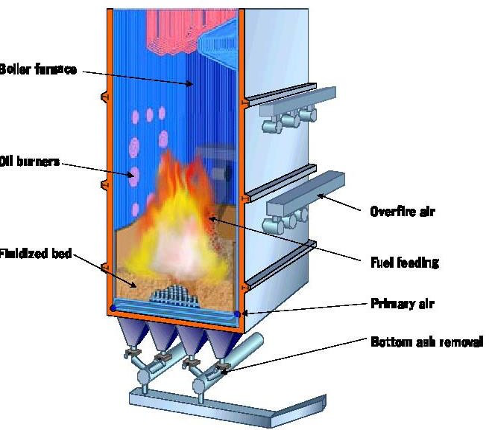

FBC

The type of combustion where there is NO progressive movement of the grate and of the fuel on the grate and no relative movement between the grate and the fuel move during the process of combustion.

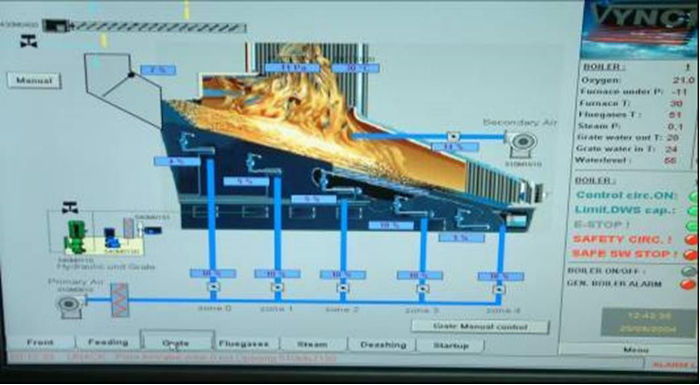

The Air-to-Fuel Ratio Control

- Fully automatic fuel control of up to 30% of the load on the boiler

- Fully automatic primary air control per zone (4 fully automatic motorized dampers)

- Fully automatic secondary air control (2 fully automatic motorized dampers)

- Tertiary air control (1 Damper)

Heat Recovery Unit – APH

Heat Recovery Unit – Economiser